正在加载图片...

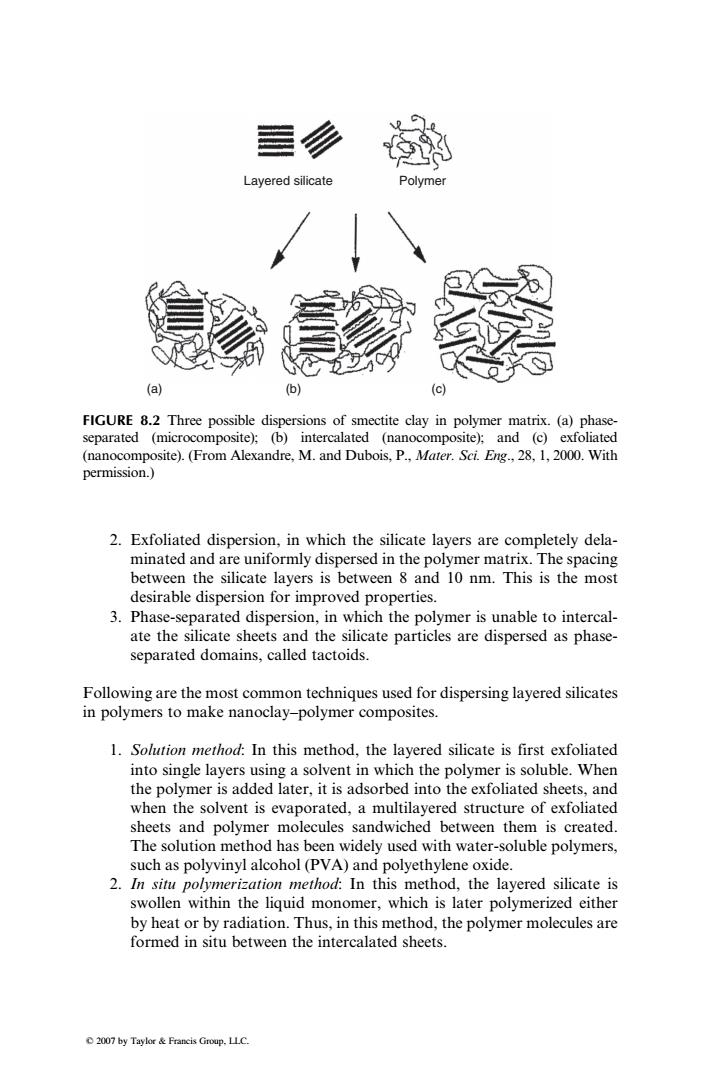

Layered silicate Polymer (a) (b) (c) FIGURE 8.2 Three possible dispersions of smectite clay in polymer matrix.(a)phase- separated (microcomposite):(b)intercalated (nanocomposite):and (c)exfoliated (nanocomposite).(From Alexandre,M.and Dubois,P.,Mater.Sci.Eng.,28,1,2000.With permission.) 2.Exfoliated dispersion,in which the silicate layers are completely dela- minated and are uniformly dispersed in the polymer matrix.The spacing between the silicate layers is between 8 and 10 nm.This is the most desirable dispersion for improved properties. 3.Phase-separated dispersion,in which the polymer is unable to intercal- ate the silicate sheets and the silicate particles are dispersed as phase- separated domains,called tactoids. Following are the most common techniques used for dispersing layered silicates in polymers to make nanoclay-polymer composites. 1.Solution method:In this method,the layered silicate is first exfoliated into single layers using a solvent in which the polymer is soluble.When the polymer is added later,it is adsorbed into the exfoliated sheets,and when the solvent is evaporated,a multilayered structure of exfoliated sheets and polymer molecules sandwiched between them is created. The solution method has been widely used with water-soluble polymers, such as polyvinyl alcohol(PVA)and polyethylene oxide. 2.In situ polymerization method:In this method,the layered silicate is swollen within the liquid monomer,which is later polymerized either by heat or by radiation.Thus,in this method,the polymer molecules are formed in situ between the intercalated sheets. 2007 by Taylor&Francis Group.LLC.2. Exfoliated dispersion, in which the silicate layers are completely delaminated and are uniformly dispersed in the polymer matrix. The spacing between the silicate layers is between 8 and 10 nm. This is the most desirable dispersion for improved properties. 3. Phase-separated dispersion, in which the polymer is unable to intercalate the silicate sheets and the silicate particles are dispersed as phaseseparated domains, called tactoids. Following are the most common techniques used for dispersing layered silicates in polymers to make nanoclay–polymer composites. 1. Solution method: In this method, the layered silicate is first exfoliated into single layers using a solvent in which the polymer is soluble. When the polymer is added later, it is adsorbed into the exfoliated sheets, and when the solvent is evaporated, a multilayered structure of exfoliated sheets and polymer molecules sandwiched between them is created. The solution method has been widely used with water-soluble polymers, such as polyvinyl alcohol (PVA) and polyethylene oxide. 2. In situ polymerization method: In this method, the layered silicate is swollen within the liquid monomer, which is later polymerized either by heat or by radiation. Thus, in this method, the polymer molecules are formed in situ between the intercalated sheets. Layered silicate Polymer (a) (b) (c) FIGURE 8.2 Three possible dispersions of smectite clay in polymer matrix. (a) phaseseparated (microcomposite); (b) intercalated (nanocomposite); and (c) exfoliated (nanocomposite). (From Alexandre, M. and Dubois, P., Mater. Sci. Eng., 28, 1, 2000. With permission.) 2007 by Taylor & Francis Group, LLC