正在加载图片...

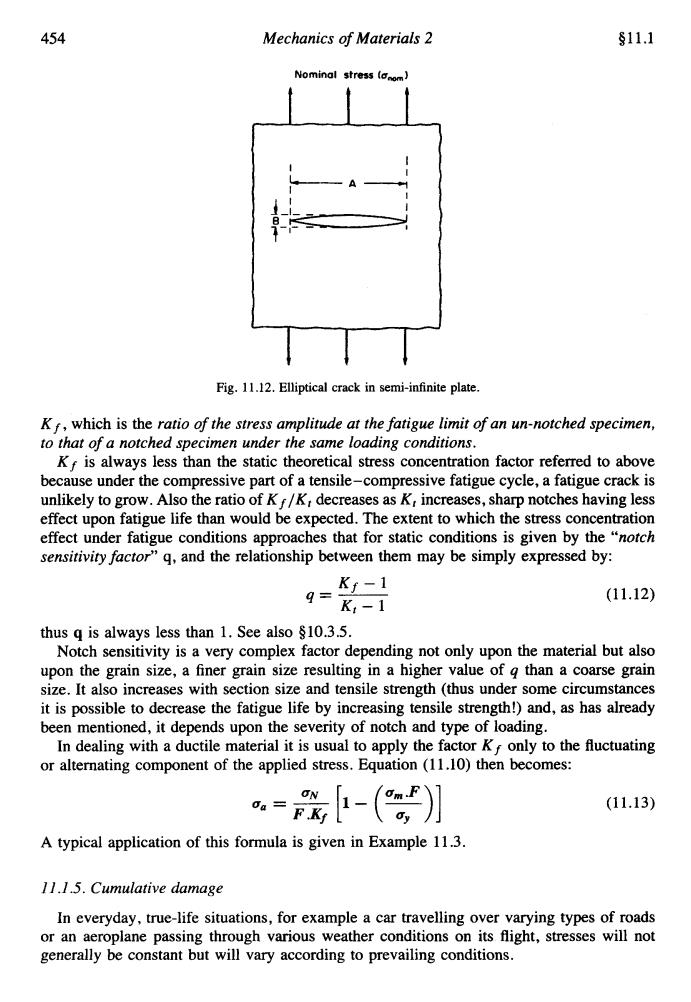

454 Mechanics of Materials 2 $11.1 ominal stress(aoom】 Fig.11.12.Elliptical crack in semi-infinite plate. Kf,which is the ratio of the stress amplitude at the fatigue limit of an un-notched specimen, to that of a notched specimen under the same loading conditions. K is always less than the static theoretical stress concentration factor referred to above because under the compressive part of a tensile-compressive fatigue cycle,a fatigue crack is unlikely to grow.Also the ratio of K/K,decreases as K,increases,sharp notches having less effect upon fatigue life than would be expected.The extent to which the stress concentration effect under fatigue conditions approaches that for static conditions is given by the "notch sensitivity factor"q,and the relationship between them may be simply expressed by: K1-1 g=K-1 (11.12) thus q is always less than 1.See also $10.3.5. Notch sensitivity is a very complex factor depending not only upon the material but also upon the grain size,a finer grain size resulting in a higher value of g than a coarse grain size.It also increases with section size and tensile strength (thus under some circumstances it is possible to decrease the fatigue life by increasing tensile strength!)and,as has already been mentioned,it depends upon the severity of notch and type of loading. In dealing with a ductile material it is usual to apply the factor Kf only to the fluctuating or alternating component of the applied stress.Equation (11.10)then becomes: =x-(】 (11.13) A typical application of this formula is given in Example 11.3. 11.1.5.Cumulative damage In everyday,true-life situations,for example a car travelling over varying types of roads or an aeroplane passing through various weather conditions on its flight,stresses will not generally be constant but will vary according to prevailing conditions.454 Mechanics of Materials 2 $11.1 Nominal stress (am) Fig. 11.12. Elliptical crack in semi-infinite plate. Kf, which is the ratio of the stress amplitude at the fatigue limit of an un-notched specimen, to rhat of a notched specimen under the same loading conditions. Kf is always less than the static theoretical stress concentration factor referred to above because under the compressive part of a tensile-compressive fatigue cycle, a fatigue crack is unlikely to grow. Also the ratio of Kf/Kr decreases as K, increases, sharp notches having less effect upon fatigue life than would be expected. The extent to which the stress concentration effect under fatigue conditions approaches that for static conditions is given by the “notch sensitivity factor” q, and the relationship between them may be simply expressed by: Kf - 1 q=- Kt - 1 (1 1.12) thus q is always less than 1. See also $10.3.5. Notch sensitivity is a very complex factor depending not only upon the material but also upon the grain size, a finer grain size resulting in a higher value of q than a coarse grain size. It also increases with section size and tensile strength (thus under some circumstances it is possible to decrease the fatigue life by increasing tensile strength!) and, as has already been mentioned, it depends upon the severity of notch and type of loading. In dealing with a ductile material it is usual to apply the factor Kf only to the fluctuating or alternating component of the applied stress. Equation (1 1 .lo) then becomes: ON u,,, .F 0, = - [l- (--)I FXf (11.13) A typical application of this formula is given in Example 11.3. I1 .I .5. Cumulative damage In everyday, true-life situations, for example a car travelling over varying types of roads or an aeroplane passing through various weather conditions on its flight, stresses will not generally be constant but will vary according to prevailing conditions