正在加载图片...

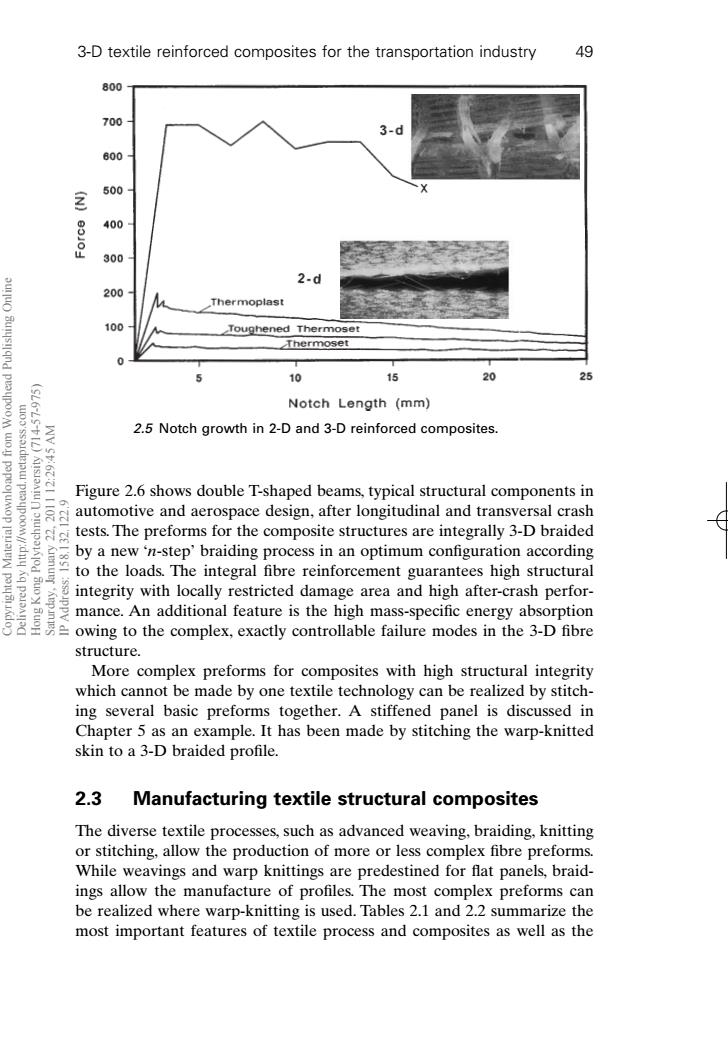

3-D textile reinforced composites for the transportation industry 49 800 700 3-d 600 500 三 400 300 2-d 200 Thermoplast 100 Toughened Thermoset Thermoset 10 15 20 25 Notch Length (mm) 2.5 Notch growth in 2-D and 3-D reinforced composites. WV St:6 202 Figure 2.6 shows double T-shaped beams,typical structural components in automotive and aerospace design,after longitudinal and transversal crash tests.The preforms for the composite structures are integrally 3-D braided by a new'n-step'braiding process in an optimum configuration according to the loads.The integral fibre reinforcement guarantees high structural 具 integrity with locally restricted damage area and high after-crash perfor- mance.An additional feature is the high mass-specific energy absorption owing to the complex,exactly controllable failure modes in the 3-D fibre structure. More complex preforms for composites with high structural integrity which cannot be made by one textile technology can be realized by stitch- ing several basic preforms together.A stiffened panel is discussed in Chapter 5 as an example.It has been made by stitching the warp-knitted skin to a 3-D braided profile. 2.3 Manufacturing textile structural composites The diverse textile processes,such as advanced weaving,braiding,knitting or stitching,allow the production of more or less complex fibre preforms. While weavings and warp knittings are predestined for flat panels,braid- ings allow the manufacture of profiles.The most complex preforms can be realized where warp-knitting is used.Tables 2.1 and 2.2 summarize the most important features of textile process and composites as well as theFigure 2.6 shows double T-shaped beams, typical structural components in automotive and aerospace design, after longitudinal and transversal crash tests. The preforms for the composite structures are integrally 3-D braided by a new ‘n-step’ braiding process in an optimum configuration according to the loads. The integral fibre reinforcement guarantees high structural integrity with locally restricted damage area and high after-crash performance. An additional feature is the high mass-specific energy absorption owing to the complex, exactly controllable failure modes in the 3-D fibre structure. More complex preforms for composites with high structural integrity which cannot be made by one textile technology can be realized by stitching several basic preforms together. A stiffened panel is discussed in Chapter 5 as an example. It has been made by stitching the warp-knitted skin to a 3-D braided profile. 2.3 Manufacturing textile structural composites The diverse textile processes, such as advanced weaving, braiding, knitting or stitching, allow the production of more or less complex fibre preforms. While weavings and warp knittings are predestined for flat panels, braidings allow the manufacture of profiles. The most complex preforms can be realized where warp-knitting is used. Tables 2.1 and 2.2 summarize the most important features of textile process and composites as well as the 3-D textile reinforced composites for the transportation industry 49 2.5 Notch growth in 2-D and 3-D reinforced composites. RIC2 7/10/99 7:25 PM Page 49 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9