正在加载图片...

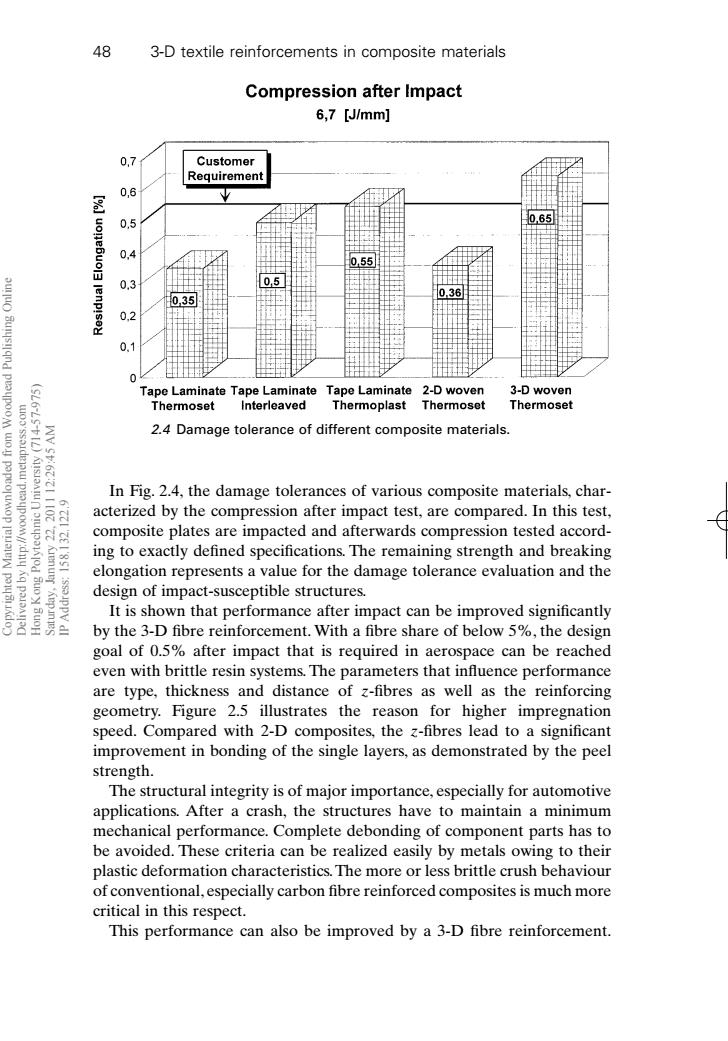

48 3-D textile reinforcements in composite materials Compression after Impact 6,7 [J/mm] 07 Customer Requirement 0,6 V 0.5 0.65 0,4 0.55 0.3 0,5 0.36 0,35 0.2 0.1 十 Tape Laminate Tape Laminate Tape Laminate 2-D woven 3-D woven Thermoset Interleaved Thermoplast Thermoset Thermoset 2.4 Damage tolerance of different composite materials. WV St:6Z 210e In Fig.2.4,the damage tolerances of various composite materials,char- acterized by the compression after impact test,are compared.In this test, 网 composite plates are impacted and afterwards compression tested accord- ing to exactly defined specifications.The remaining strength and breaking elongation represents a value for the damage tolerance evaluation and the design of impact-susceptible structures. It is shown that performance after impact can be improved significantly by the 3-D fibre reinforcement.With a fibre share of below 5%,the design goal of 0.5%after impact that is required in aerospace can be reached even with brittle resin systems.The parameters that influence performance are type,thickness and distance of z-fibres as well as the reinforcing geometry.Figure 2.5 illustrates the reason for higher impregnation speed.Compared with 2-D composites,the z-fibres lead to a significant improvement in bonding of the single layers,as demonstrated by the peel strength. The structural integrity is of major importance,especially for automotive applications.After a crash,the structures have to maintain a minimum mechanical performance.Complete debonding of component parts has to be avoided.These criteria can be realized easily by metals owing to their plastic deformation characteristics.The more or less brittle crush behaviour of conventional,especially carbon fibre reinforced composites is much more critical in this respect. This performance can also be improved by a 3-D fibre reinforcement.In Fig. 2.4, the damage tolerances of various composite materials, characterized by the compression after impact test, are compared. In this test, composite plates are impacted and afterwards compression tested according to exactly defined specifications. The remaining strength and breaking elongation represents a value for the damage tolerance evaluation and the design of impact-susceptible structures. It is shown that performance after impact can be improved significantly by the 3-D fibre reinforcement. With a fibre share of below 5%, the design goal of 0.5% after impact that is required in aerospace can be reached even with brittle resin systems. The parameters that influence performance are type, thickness and distance of z-fibres as well as the reinforcing geometry. Figure 2.5 illustrates the reason for higher impregnation speed. Compared with 2-D composites, the z-fibres lead to a significant improvement in bonding of the single layers, as demonstrated by the peel strength. The structural integrity is of major importance, especially for automotive applications. After a crash, the structures have to maintain a minimum mechanical performance. Complete debonding of component parts has to be avoided. These criteria can be realized easily by metals owing to their plastic deformation characteristics. The more or less brittle crush behaviour of conventional, especially carbon fibre reinforced composites is much more critical in this respect. This performance can also be improved by a 3-D fibre reinforcement. 48 3-D textile reinforcements in composite materials 2.4 Damage tolerance of different composite materials. RIC2 7/10/99 7:25 PM Page 48 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:29:45 AM IP Address: 158.132.122.9