正在加载图片...

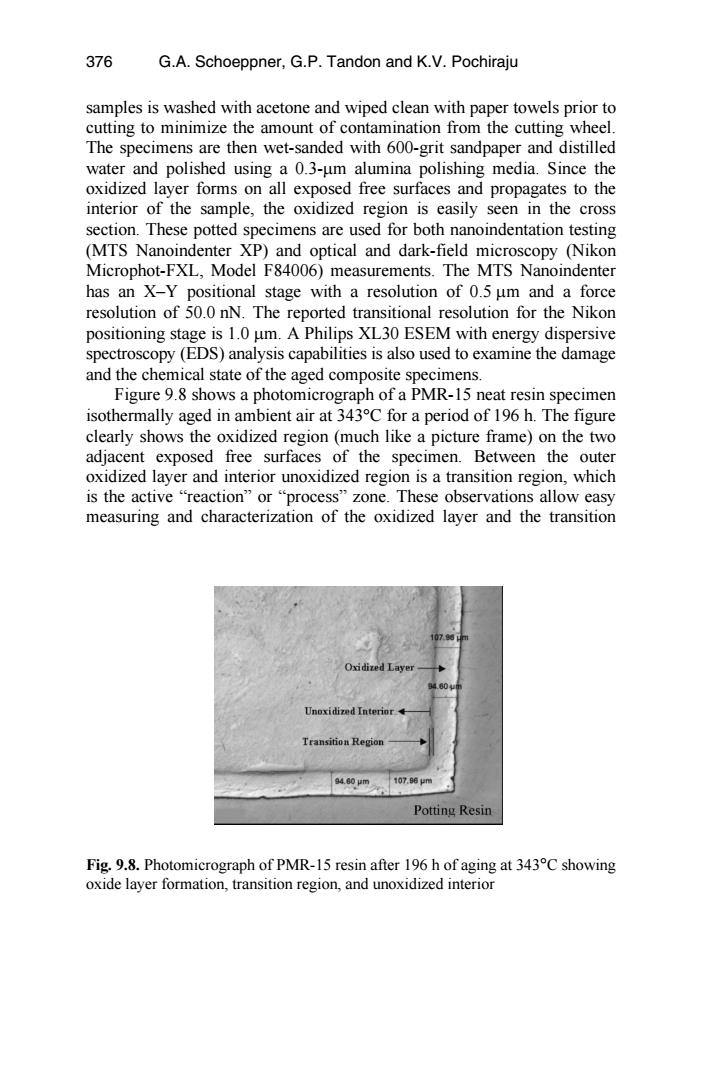

376 G.A.Schoeppner,G.P.Tandon and K.V.Pochiraju samples is washed with acetone and wiped clean with paper towels prior to cutting to minimize the amount of contamination from the cutting wheel. The specimens are then wet-sanded with 600-grit sandpaper and distilled water and polished using a 0.3-um alumina polishing media.Since the oxidized layer forms on all exposed free surfaces and propagates to the interior of the sample,the oxidized region is easily seen in the cross section.These potted specimens are used for both nanoindentation testing (MTS Nanoindenter XP)and optical and dark-field microscopy (Nikon Microphot-FXL,Model F84006)measurements.The MTS Nanoindenter has an X-Y positional stage with a resolution of 0.5 um and a force resolution of 50.0 nN.The reported transitional resolution for the Nikon positioning stage is 1.0 um.A Philips XL30 ESEM with energy dispersive spectroscopy(EDS)analysis capabilities is also used to examine the damage and the chemical state of the aged composite specimens. Figure 9.8 shows a photomicrograph of a PMR-15 neat resin specimen isothermally aged in ambient air at 343C for a period of 196 h.The figure clearly shows the oxidized region(much like a picture frame)on the two adjacent exposed free surfaces of the specimen.Between the outer oxidized layer and interior unoxidized region is a transition region,which is the active "reaction"or "process"zone.These observations allow easy measuring and characterization of the oxidized layer and the transition Oxidized Laye Unoxidized Interior Transition Region 94.60m107.6pm Potting Resin Fig.9.8.Photomicrograph of PMR-15 resin after 196 h of aging at 343C showing oxide layer formation,transition region,and unoxidized interiorsection. These potted specimens are used for both nanoindentation testing (MTS Nanoindenter XP) and optical and dark-field microscopy (Nikon Microphot-FXL, Model F84006) measurements. The MTS Nanoindenter has an X–Y positional stage with a resolution of 0.5 µm and a force resolution of 50.0 nN. The reported transitional resolution for the Nikon positioning stage is 1.0 µm. A Philips XL30 ESEM with energy dispersive spectroscopy (EDS) analysis capabilities is also used to examine the damage and the chemical state of the aged composite specimens. Figure 9.8 shows a photomicrograph of a PMR-15 neat resin specimen isothermally aged in ambient air at 343°C for a period of 196 h. The figure clearly shows the oxidized region (much like a picture frame) on the two adjacent exposed free surfaces of the specimen. Between the outer oxidized layer and interior unoxidized region is a transition region, which is the active “reaction” or “process” zone. These observations allow easy measuring and characterization of the oxidized layer and the transition Fig. 9.8. Photomicrograph of PMR-15 resin after 196 h of aging at 343°C showing oxide layer formation, transition region, and unoxidized interior water and polished using a 0.3-µm alumina polishing media. Since the oxidized layer forms on all exposed free surfaces and propagates to the interior of the sample, the oxidized region is easily seen in the cross samples is washed with acetone and wiped clean with paper towels prior to cutting to minimize the amount of contamination from the cutting wheel. The specimens are then wet-sanded with 600-grit sandpaper and distilled 376 G.A. Schoeppner, G.P. Tandon and K.V. Pochiraju