正在加载图片...

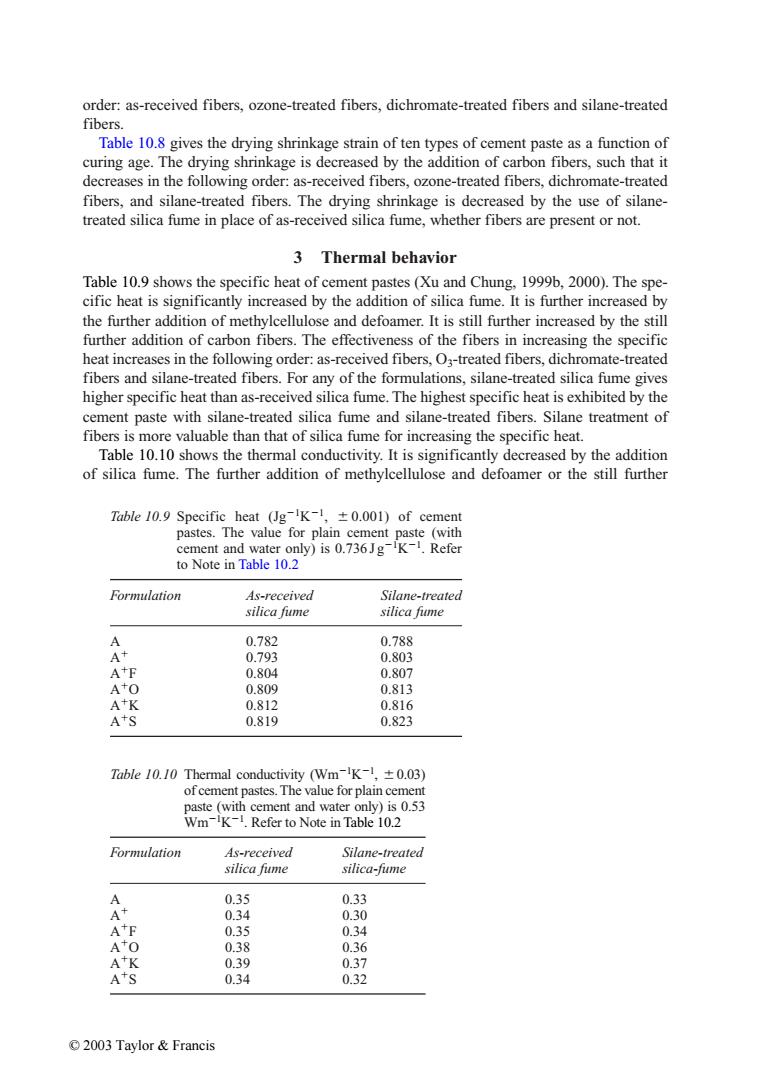

order:as-received fibers,ozone-treated fibers,dichromate-treated fibers and silane-treated fibers. Table 10.8 gives the drying shrinkage strain of ten types of cement paste as a function of curing age.The drying shrinkage is decreased by the addition of carbon fibers,such that it decreases in the following order:as-received fibers,ozone-treated fibers,dichromate-treated fibers,and silane-treated fibers.The drying shrinkage is decreased by the use of silane- treated silica fume in place of as-received silica fume,whether fibers are present or not. 3 Thermal behavior Table 10.9 shows the specific heat of cement pastes(Xu and Chung,1999b,2000).The spe- cific heat is significantly increased by the addition of silica fume.It is further increased by the further addition of methylcellulose and defoamer.It is still further increased by the still further addition of carbon fibers.The effectiveness of the fibers in increasing the specific heat increases in the following order:as-received fibers,O3-treated fibers,dichromate-treated fibers and silane-treated fibers.For any of the formulations,silane-treated silica fume gives higher specific heat than as-received silica fume.The highest specific heat is exhibited by the cement paste with silane-treated silica fume and silane-treated fibers.Silane treatment of fibers is more valuable than that of silica fume for increasing the specific heat Table 10.10 shows the thermal conductivity.It is significantly decreased by the addition of silica fume.The further addition of methylcellulose and defoamer or the still further Table 10.9 Specific heat (Jg-K-1,0.001)of cement pastes.The value for plain cement paste (with cement and water only)is 0.736Jg-K-.Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 0.782 0.788 A+ 0.793 0.803 A+F 0.804 0.807 AO 0.809 0.813 AK 0.812 0.816 A+S 0.819 0.823 Table 10.10 Thermal conductivity (Wm-K-,0.03) of cement pastes.The value for plain cement paste (with cement and water only)is 0.53 Wm-K-.Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica-fume A 0.35 0.33 A+ 0.34 0.30 A 0.35 0.34 AO 0.38 0.36 AK 0.39 0.37 AS 0.34 0.32 ©2003 Taylor&Francisorder: as-received fibers, ozone-treated fibers, dichromate-treated fibers and silane-treated fibers. Table 10.8 gives the drying shrinkage strain of ten types of cement paste as a function of curing age. The drying shrinkage is decreased by the addition of carbon fibers, such that it decreases in the following order: as-received fibers, ozone-treated fibers, dichromate-treated fibers, and silane-treated fibers. The drying shrinkage is decreased by the use of silanetreated silica fume in place of as-received silica fume, whether fibers are present or not. 3 Thermal behavior Table 10.9 shows the specific heat of cement pastes (Xu and Chung, 1999b, 2000). The specific heat is significantly increased by the addition of silica fume. It is further increased by the further addition of methylcellulose and defoamer. It is still further increased by the still further addition of carbon fibers. The effectiveness of the fibers in increasing the specific heat increases in the following order: as-received fibers, O3-treated fibers, dichromate-treated fibers and silane-treated fibers. For any of the formulations, silane-treated silica fume gives higher specific heat than as-received silica fume. The highest specific heat is exhibited by the cement paste with silane-treated silica fume and silane-treated fibers. Silane treatment of fibers is more valuable than that of silica fume for increasing the specific heat. Table 10.10 shows the thermal conductivity. It is significantly decreased by the addition of silica fume. The further addition of methylcellulose and defoamer or the still further Table 10.9 Specific heat (Jg1 K1 , 0.001) of cement pastes. The value for plain cement paste (with cement and water only) is 0.736 J g1 K1 . Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica fume A 0.782 0.788 A 0.793 0.803 AF 0.804 0.807 AO 0.809 0.813 AK 0.812 0.816 AS 0.819 0.823 Table 10.10 Thermal conductivity (Wm1 K1 , 0.03) of cement pastes.The value for plain cement paste (with cement and water only) is 0.53 Wm1 K1 . Refer to Note in Table 10.2 Formulation As-received Silane-treated silica fume silica-fume A 0.35 0.33 A 0.34 0.30 AF 0.35 0.34 AO 0.38 0.36 AK 0.39 0.37 AS 0.34 0.32 © 2003 Taylor & Francis����������