正在加载图片...

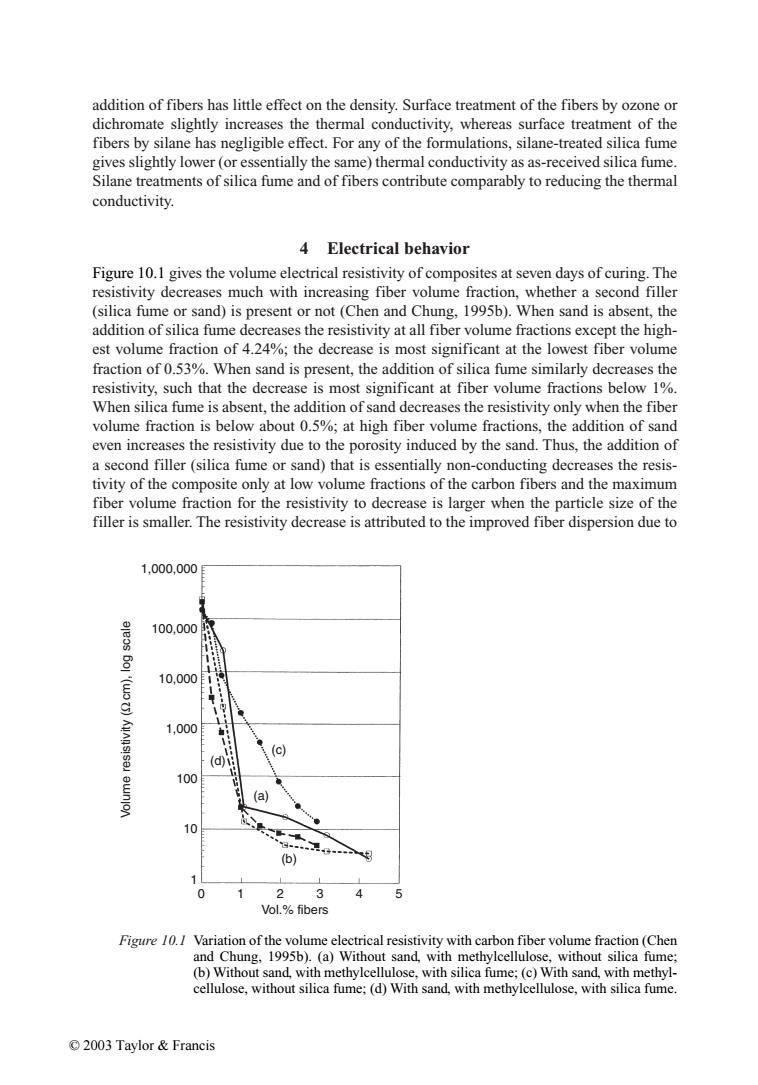

addition of fibers has little effect on the density.Surface treatment of the fibers by ozone or dichromate slightly increases the thermal conductivity,whereas surface treatment of the fibers by silane has negligible effect.For any of the formulations,silane-treated silica fume gives slightly lower(or essentially the same)thermal conductivity as as-received silica fume. Silane treatments of silica fume and of fibers contribute comparably to reducing the thermal conductivity. 4 Electrical behavior Figure 10.1 gives the volume electrical resistivity of composites at seven days of curing.The resistivity decreases much with increasing fiber volume fraction,whether a second filler (silica fume or sand)is present or not (Chen and Chung,1995b).When sand is absent,the addition of silica fume decreases the resistivity at all fiber volume fractions except the high- est volume fraction of 4.24%;the decrease is most significant at the lowest fiber volume fraction of 0.53%.When sand is present,the addition of silica fume similarly decreases the resistivity,such that the decrease is most significant at fiber volume fractions below 1%. When silica fume is absent,the addition of sand decreases the resistivity only when the fiber volume fraction is below about 0.5%;at high fiber volume fractions,the addition of sand even increases the resistivity due to the porosity induced by the sand.Thus,the addition of a second filler(silica fume or sand)that is essentially non-conducting decreases the resis- tivity of the composite only at low volume fractions of the carbon fibers and the maximum fiber volume fraction for the resistivity to decrease is larger when the particle size of the filler is smaller.The resistivity decrease is attributed to the improved fiber dispersion due to 1.000,000 100,000 g (wo 10,0001 g 1,000 11 (c) (d)i: 100 (a) 10 (b) 0 2 3 4 5 Vol.%fibers Figure 10.I Variation of the volume electrical resistivity with carbon fiber volume fraction(Chen and Chung,1995b).(a)Without sand,with methylcellulose,without silica fume; (b)Without sand,with methylcellulose,with silica fume;(c)With sand,with methyl- cellulose,without silica fume;(d)With sand,with methylcellulose,with silica fume. ©2003 Taylor&Francisaddition of fibers has little effect on the density. Surface treatment of the fibers by ozone or dichromate slightly increases the thermal conductivity, whereas surface treatment of the fibers by silane has negligible effect. For any of the formulations, silane-treated silica fume gives slightly lower (or essentially the same) thermal conductivity as as-received silica fume. Silane treatments of silica fume and of fibers contribute comparably to reducing the thermal conductivity. 4 Electrical behavior Figure 10.1 gives the volume electrical resistivity of composites at seven days of curing. The resistivity decreases much with increasing fiber volume fraction, whether a second filler (silica fume or sand) is present or not (Chen and Chung, 1995b). When sand is absent, the addition of silica fume decreases the resistivity at all fiber volume fractions except the highest volume fraction of 4.24%; the decrease is most significant at the lowest fiber volume fraction of 0.53%. When sand is present, the addition of silica fume similarly decreases the resistivity, such that the decrease is most significant at fiber volume fractions below 1%. When silica fume is absent, the addition of sand decreases the resistivity only when the fiber volume fraction is below about 0.5%; at high fiber volume fractions, the addition of sand even increases the resistivity due to the porosity induced by the sand. Thus, the addition of a second filler (silica fume or sand) that is essentially non-conducting decreases the resistivity of the composite only at low volume fractions of the carbon fibers and the maximum fiber volume fraction for the resistivity to decrease is larger when the particle size of the filler is smaller. The resistivity decrease is attributed to the improved fiber dispersion due to Figure 10.1 Variation of the volume electrical resistivity with carbon fiber volume fraction (Chen and Chung, 1995b). (a) Without sand, with methylcellulose, without silica fume; (b) Without sand, with methylcellulose, with silica fume; (c) With sand, with methylcellulose, without silica fume; (d) With sand, with methylcellulose, with silica fume. 1,000,000 100,000 10,000 1,000 100 Volume resistivity ( Ωcm), log scale 10 1 012 (b) Vol.% fibers (a) (d) (c) 345 © 2003 Taylor & Francis