正在加载图片...

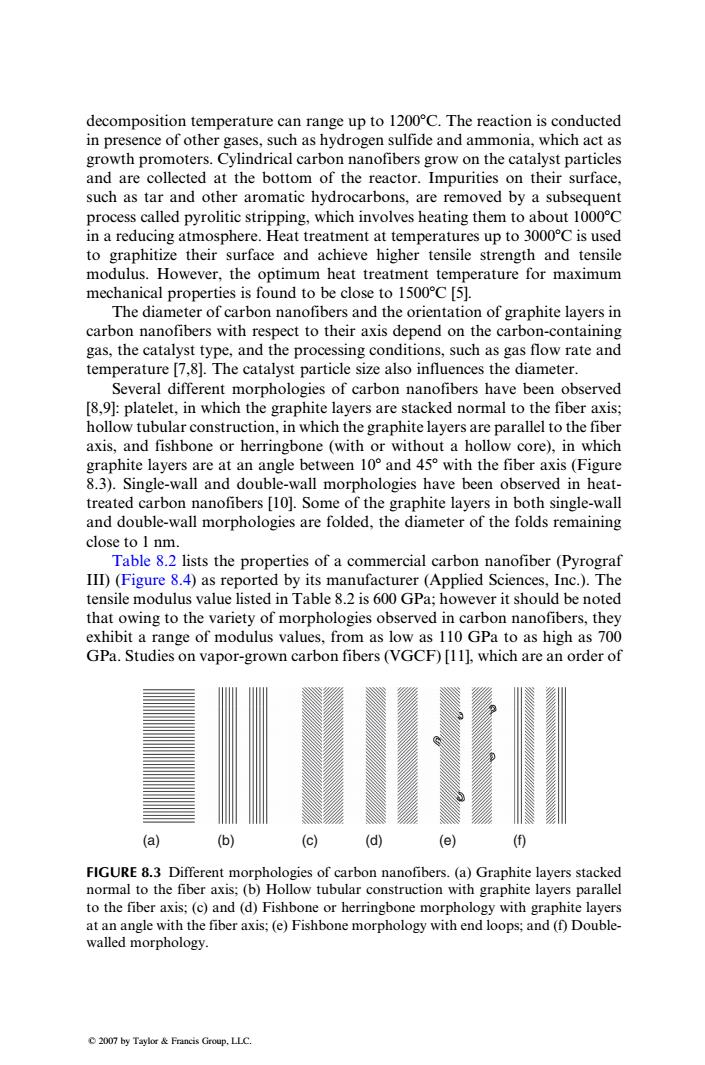

decomposition temperature can range up to 1200C.The reaction is conducted in presence of other gases,such as hydrogen sulfide and ammonia,which act as growth promoters.Cylindrical carbon nanofibers grow on the catalyst particles and are collected at the bottom of the reactor.Impurities on their surface, such as tar and other aromatic hydrocarbons,are removed by a subsequent process called pyrolitic stripping,which involves heating them to about 1000C in a reducing atmosphere.Heat treatment at temperatures up to 3000C is used to graphitize their surface and achieve higher tensile strength and tensile modulus.However,the optimum heat treatment temperature for maximum mechanical properties is found to be close to 1500C [5]. The diameter of carbon nanofibers and the orientation of graphite layers in carbon nanofibers with respect to their axis depend on the carbon-containing gas,the catalyst type,and the processing conditions,such as gas flow rate and temperature [7,8].The catalyst particle size also influences the diameter. Several different morphologies of carbon nanofibers have been observed [8,9]:platelet,in which the graphite layers are stacked normal to the fiber axis; hollow tubular construction,in which the graphite layers are parallel to the fiber axis,and fishbone or herringbone (with or without a hollow core),in which graphite layers are at an angle between 10 and 45 with the fiber axis(Figure 8.3).Single-wall and double-wall morphologies have been observed in heat- treated carbon nanofibers [10].Some of the graphite layers in both single-wall and double-wall morphologies are folded,the diameter of the folds remaining close to I nm. Table 8.2 lists the properties of a commercial carbon nanofiber(Pyrograf III)(Figure 8.4)as reported by its manufacturer (Applied Sciences,Inc.).The tensile modulus value listed in Table 8.2 is 600 GPa;however it should be noted that owing to the variety of morphologies observed in carbon nanofibers,they exhibit a range of modulus values,from as low as 110 GPa to as high as 700 GPa.Studies on vapor-grown carbon fibers (VGCF)[11],which are an order of (a) (b) (c) (d) (e) (0 FIGURE 8.3 Different morphologies of carbon nanofibers.(a)Graphite layers stacked normal to the fiber axis;(b)Hollow tubular construction with graphite layers parallel to the fiber axis;(c)and (d)Fishbone or herringbone morphology with graphite layers at an angle with the fiber axis;(e)Fishbone morphology with end loops;and (f)Double- walled morphology. 2007 by Taylor Francis Group,LLC.decomposition temperature can range up to 12008C. The reaction is conducted in presence of other gases, such as hydrogen sulfide and ammonia, which act as growth promoters. Cylindrical carbon nanofibers grow on the catalyst particles and are collected at the bottom of the reactor. Impurities on their surface, such as tar and other aromatic hydrocarbons, are removed by a subsequent process called pyrolitic stripping, which involves heating them to about 10008C in a reducing atmosphere. Heat treatment at temperatures up to 30008C is used to graphitize their surface and achieve higher tensile strength and tensile modulus. However, the optimum heat treatment temperature for maximum mechanical properties is found to be close to 15008C [5]. The diameter of carbon nanofibers and the orientation of graphite layers in carbon nanofibers with respect to their axis depend on the carbon-containing gas, the catalyst type, and the processing conditions, such as gas flow rate and temperature [7,8]. The catalyst particle size also influences the diameter. Several different morphologies of carbon nanofibers have been observed [8,9]: platelet, in which the graphite layers are stacked normal to the fiber axis; hollow tubular construction, in which the graphite layers are parallel to the fiber axis, and fishbone or herringbone (with or without a hollow core), in which graphite layers are at an angle between 108 and 458 with the fiber axis (Figure 8.3). Single-wall and double-wall morphologies have been observed in heattreated carbon nanofibers [10]. Some of the graphite layers in both single-wall and double-wall morphologies are folded, the diameter of the folds remaining close to 1 nm. Table 8.2 lists the properties of a commercial carbon nanofiber (Pyrograf III) (Figure 8.4) as reported by its manufacturer (Applied Sciences, Inc.). The tensile modulus value listed in Table 8.2 is 600 GPa; however it should be noted that owing to the variety of morphologies observed in carbon nanofibers, they exhibit a range of modulus values, from as low as 110 GPa to as high as 700 GPa. Studies on vapor-grown carbon fibers (VGCF) [11], which are an order of (a) (b) (c) (d) (e) (f) FIGURE 8.3 Different morphologies of carbon nanofibers. (a) Graphite layers stacked normal to the fiber axis; (b) Hollow tubular construction with graphite layers parallel to the fiber axis; (c) and (d) Fishbone or herringbone morphology with graphite layers at an angle with the fiber axis; (e) Fishbone morphology with end loops; and (f) Doublewalled morphology. 2007 by Taylor & Francis Group, LLC