正在加载图片...

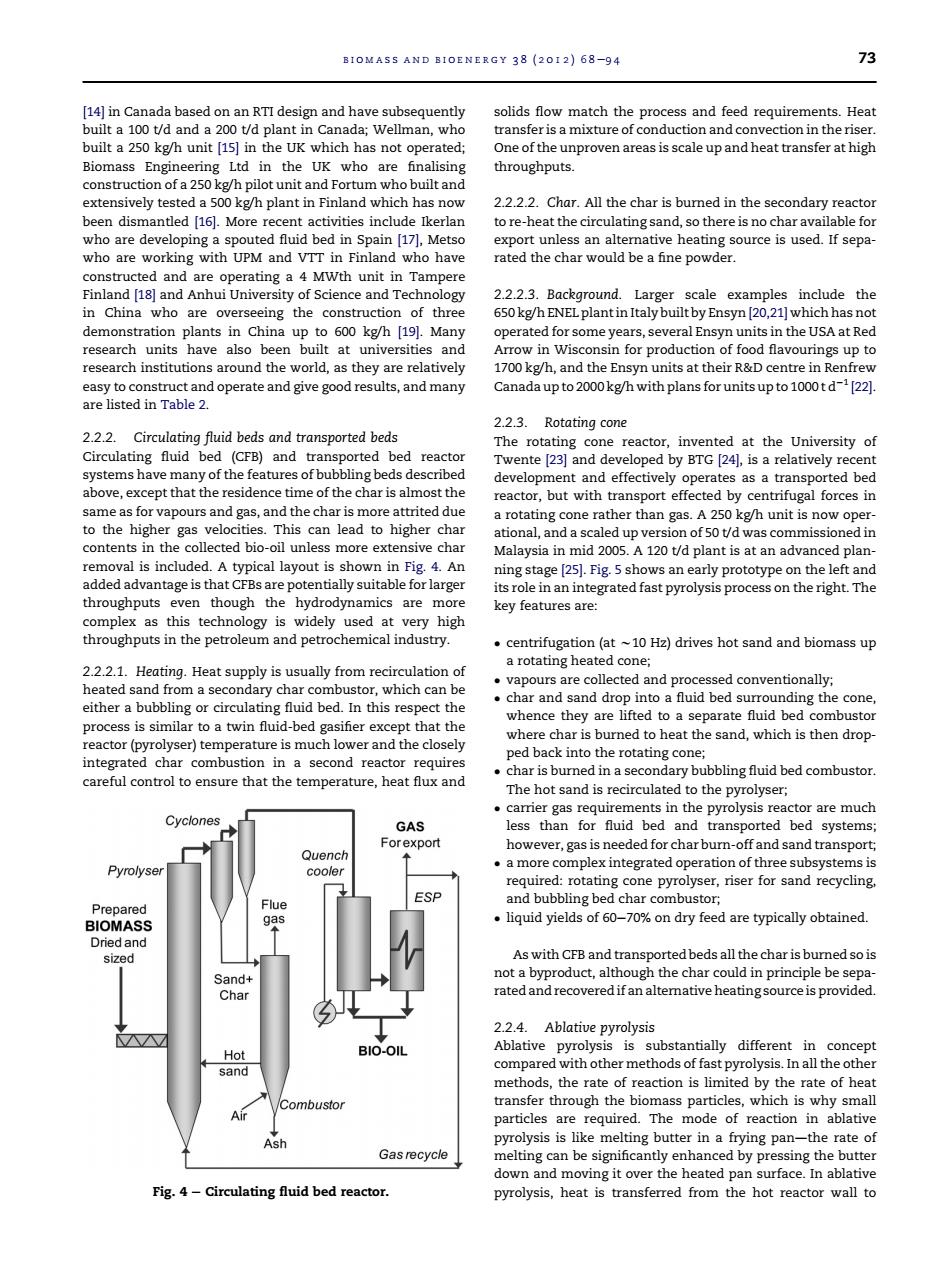

BIOMASS AND BIOENERGY 38 (2012)68-94 73 [14]in Canada based on an RTI design and have subsequently solids flow match the process and feed requirements.Heat built a 100 t/d and a 200 t/d plant in Canada;Wellman,who transfer is a mixture of conduction and convection in the riser. built a 250 kg/h unit [15]in the UK which has not operated; One of the unproven areas is scale up and heat transfer at high Biomass Engineering Ltd in the UK who are finalising throughputs. construction of a 250 kg/h pilot unit and Fortum who built and extensively tested a 500 kg/h plant in Finland which has now 2.2.2.2.Char.All the char is burned in the secondary reactor been dismantled [16].More recent activities include Ikerlan to re-heat the circulating sand,so there is no char available for who are developing a spouted fluid bed in Spain [17].Metso export unless an alternative heating source is used.If sepa who are working with UPM and VTT in Finland who have rated the char would be a fine powder. constructed and are operating a 4 MWth unit in Tampere Finland [18]and Anhui University of Science and Technology 2.2.2.3.Background.Larger scale examples include the in China who are overseeing the construction of three 650kg/h ENEL plant in Italy built by Ensyn [20,21]which has not demonstration plants in China up to 600 kg/h [19].Many operated for some years,several Ensyn units in the USA at Red research units have also been built at universities and Arrow in Wisconsin for production of food flavourings up to research institutions around the world,as they are relatively 1700 kg/h,and the Ensyn units at their R&D centre in Renfrew easy to construct and operate and give good results,and many Canadaup to 2000kg/h with plans for unitsup to 1000td-1[22]. are listed in Table 2. 2.2.3.Rotating cone 2.2.2.Circulating fluid beds and transported beds The rotating cone reactor,invented at the University of Circulating fluid bed (CFB)and transported bed reactor Twente [23]and developed by BTG [241,is a relatively recent systems have many of the features of bubbling beds described development and effectively operates as a transported bed above,except that the residence time of the char is almost the reactor,but with transport effected by centrifugal forces in same as for vapours and gas,and the char is more attrited due a rotating cone rather than gas.A 250 kg/h unit is now oper- to the higher gas velocities.This can lead to higher char ational,and a scaled up version of 50t/d was commissioned in contents in the collected bio-oil unless more extensive char Malaysia in mid 2005.A 120 t/d plant is at an advanced plan- removal is included.A typical layout is shown in Fig.4.An ning stage [25].Fig.5 shows an early prototype on the left and added advantage is that CFBs are potentially suitable for larger its role in an integrated fast pyrolysis process on the right.The throughputs even though the hydrodynamics are more key features are: complex as this technology is widely used at very high throughputs in the petroleum and petrochemical industry. centrifugation(at~10 Hz)drives hot sand and biomass up a rotating heated cone; 2.2.2.1.Heating.Heat supply is usually from recirculation of vapours are collected and processed conventionally; heated sand from a secondary char combustor,which can be char and sand drop into a fluid bed surrounding the cone, either a bubbling or circulating fluid bed.In this respect the process is similar to a twin fluid-bed gasifier except that the whence they are lifted to a separate fluid bed combustor where char is burned to heat the sand,which is then drop reactor(pyrolyser)temperature is much lower and the closely ped back into the rotating cone; integrated char combustion in a second reactor requires char is burned in a secondary bubbling fluid bed combustor. careful control to ensure that the temperature,heat flux and The hot sand is recirculated to the pyrolyser; carrier gas requirements in the pyrolysis reactor are much Cyclones GAS less than for fluid bed and transported bed systems; Forexport however,gas is needed for char burn-off and sand transport; Quench Pyrolyser a more complex integrated operation of three subsystems is cooler required:rotating cone pyrolyser,riser for sand recycling, ESP and bubbling bed char combustor; Prepared Flue BIOMASS gas liquid yields of 60-70%on dry feed are typically obtained. Dried and sized As with CFB and transported beds all the char is burned so is Sand+ not a byproduct,although the char could in principle be sepa- Char rated and recovered if an alterative heatingsource is provided. 2.2.4.Ablative pyrolysis 77 Hot BIO-OIL Ablative pyrolysis is substantially different in concept sand compared with other methods of fast pyrolysis.In all the other methods,the rate of reaction is limited by the rate of heat Combustor transfer through the biomass particles,which is why small AIr particles are required.The mode of reaction in ablative Ash pyrolysis is like melting butter in a frying pan-the rate of Gas recycle melting can be significantly enhanced by pressing the butter down and moving it over the heated pan surface.In ablative Fig.4-Circulating fluid bed reactor. pyrolysis,heat is transferred from the hot reactor wall to[14] in Canada based on an RTI design and have subsequently built a 100 t/d and a 200 t/d plant in Canada; Wellman, who built a 250 kg/h unit [15] in the UK which has not operated; Biomass Engineering Ltd in the UK who are finalising construction of a 250 kg/h pilot unit and Fortum who built and extensively tested a 500 kg/h plant in Finland which has now been dismantled [16]. More recent activities include Ikerlan who are developing a spouted fluid bed in Spain [17], Metso who are working with UPM and VTT in Finland who have constructed and are operating a 4 MWth unit in Tampere Finland [18] and Anhui University of Science and Technology in China who are overseeing the construction of three demonstration plants in China up to 600 kg/h [19]. Many research units have also been built at universities and research institutions around the world, as they are relatively easy to construct and operate and give good results, and many are listed in Table 2. 2.2.2. Circulating fluid beds and transported beds Circulating fluid bed (CFB) and transported bed reactor systems have many of the features of bubbling beds described above, except that the residence time of the char is almost the same as for vapours and gas, and the char is more attrited due to the higher gas velocities. This can lead to higher char contents in the collected bio-oil unless more extensive char removal is included. A typical layout is shown in Fig. 4. An added advantage is that CFBs are potentially suitable for larger throughputs even though the hydrodynamics are more complex as this technology is widely used at very high throughputs in the petroleum and petrochemical industry. 2.2.2.1. Heating. Heat supply is usually from recirculation of heated sand from a secondary char combustor, which can be either a bubbling or circulating fluid bed. In this respect the process is similar to a twin fluid-bed gasifier except that the reactor (pyrolyser) temperature is much lower and the closely integrated char combustion in a second reactor requires careful control to ensure that the temperature, heat flux and solids flow match the process and feed requirements. Heat transfer is a mixture of conduction and convection in the riser. One of the unproven areas is scale up and heat transfer at high throughputs. 2.2.2.2. Char. All the char is burned in the secondary reactor to re-heat the circulating sand, so there is no char available for export unless an alternative heating source is used. If separated the char would be a fine powder. 2.2.2.3. Background. Larger scale examples include the 650 kg/h ENEL plant in Italy built by Ensyn [20,21] which has not operated for some years, several Ensyn units in the USA at Red Arrow in Wisconsin for production of food flavourings up to 1700 kg/h, and the Ensyn units at their R&D centre in Renfrew Canada up to 2000 kg/h with plans for units up to 1000 t d1 [22]. 2.2.3. Rotating cone The rotating cone reactor, invented at the University of Twente [23] and developed by BTG [24], is a relatively recent development and effectively operates as a transported bed reactor, but with transport effected by centrifugal forces in a rotating cone rather than gas. A 250 kg/h unit is now operational, and a scaled up version of 50 t/d was commissioned in Malaysia in mid 2005. A 120 t/d plant is at an advanced planning stage [25]. Fig. 5 shows an early prototype on the left and its role in an integrated fast pyrolysis process on the right. The key features are: centrifugation (at w10 Hz) drives hot sand and biomass up a rotating heated cone; vapours are collected and processed conventionally; char and sand drop into a fluid bed surrounding the cone, whence they are lifted to a separate fluid bed combustor where char is burned to heat the sand, which is then dropped back into the rotating cone; char is burned in a secondary bubbling fluid bed combustor. The hot sand is recirculated to the pyrolyser; carrier gas requirements in the pyrolysis reactor are much less than for fluid bed and transported bed systems; however, gas is needed for char burn-off and sand transport; a more complex integrated operation of three subsystems is required: rotating cone pyrolyser, riser for sand recycling, and bubbling bed char combustor; liquid yields of 60e70% on dry feed are typically obtained. As with CFB and transported beds all the char is burned so is not a byproduct, although the char could in principle be separated and recovered if an alternative heating source is provided. 2.2.4. Ablative pyrolysis Ablative pyrolysis is substantially different in concept compared with other methods of fast pyrolysis. In all the other methods, the rate of reaction is limited by the rate of heat transfer through the biomass particles, which is why small particles are required. The mode of reaction in ablative pyrolysis is like melting butter in a frying pandthe rate of melting can be significantly enhanced by pressing the butter down and moving it over the heated pan surface. In ablative Fig. 4 e Circulating fluid bed reactor. pyrolysis, heat is transferred from the hot reactor wall to biomass and bioenergy 38 (2012) 68 e9 4 73�������