正在加载图片...

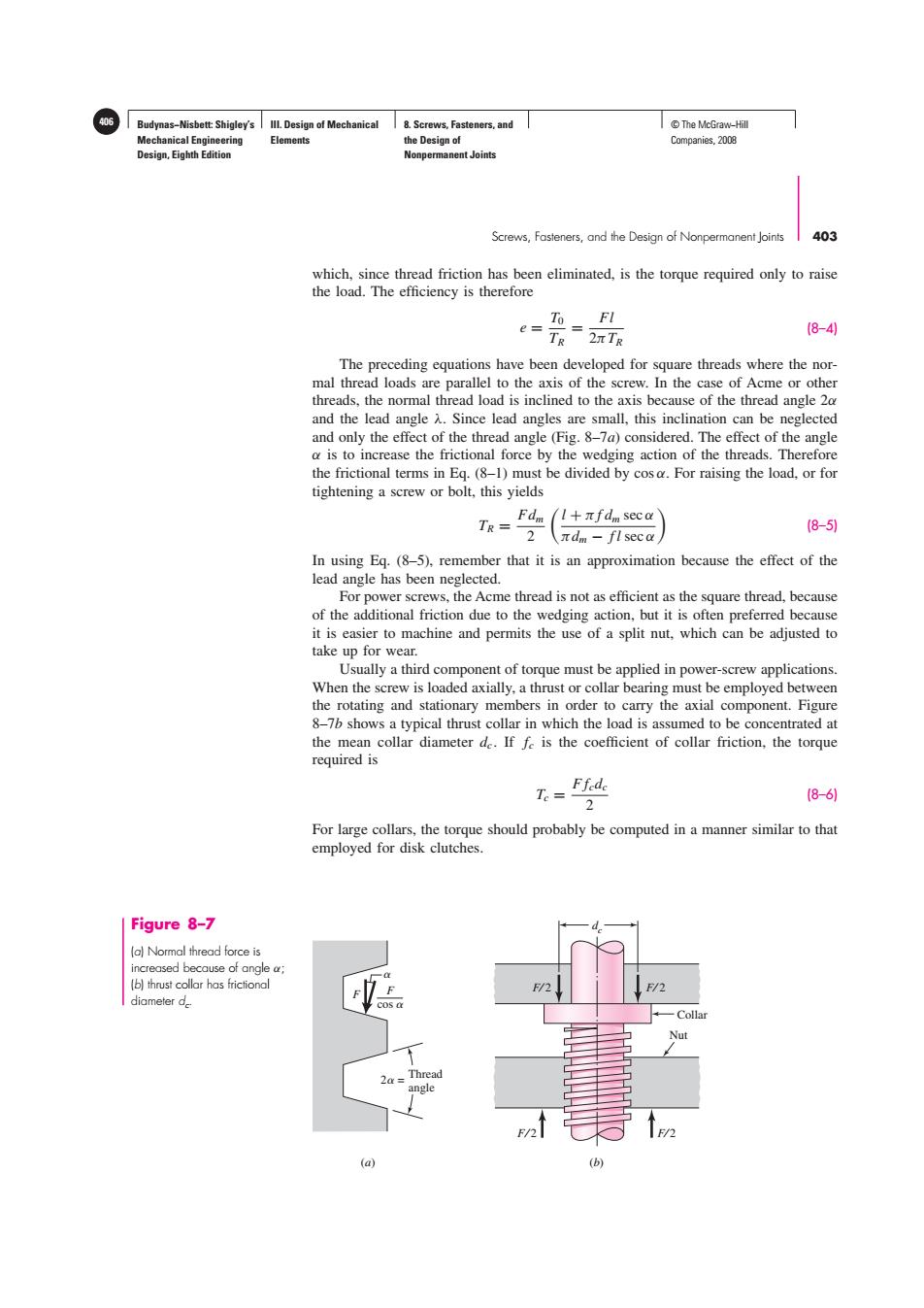

06 Budynas-Nisbett:Shigley's Ill.Design of Mechanical 8.Screws,Fasteners,and T©The McGraw-Hill Mechanical Engineering Elements the Design of Companies,2008 Design,Eighth Edition Nonpermanent Joints Screws,Fasteners,and the Design of Nonpermanent Joints 403 which,since thread friction has been eliminated,is the torque required only to raise the load.The efficiency is therefore To Fl e= TR 2TR (8-4④ The preceding equations have been developed for square threads where the nor- mal thread loads are parallel to the axis of the screw.In the case of Acme or other threads,the normal thread load is inclined to the axis because of the thread angle 20 and the lead angle A.Since lead angles are small,this inclination can be neglected and only the effect of the thread angle(Fig.8-7a)considered.The effect of the angle o is to increase the frictional force by the wedging action of the threads.Therefore the frictional terms in Eq.(8-1)must be divided by cos a.For raising the load,or for tightening a screw or bolt,this yields Fdm TR=2 l+πf d sec a (8-51 πdm-fl sec In using Eq.(8-5),remember that it is an approximation because the effect of the lead angle has been neglected. For power screws,the Acme thread is not as efficient as the square thread,because of the additional friction due to the wedging action,but it is often preferred because it is easier to machine and permits the use of a split nut,which can be adjusted to take up for wear. Usually a third component of torque must be applied in power-screw applications. When the screw is loaded axially,a thrust or collar bearing must be employed between the rotating and stationary members in order to carry the axial component.Figure 8-7b shows a typical thrust collar in which the load is assumed to be concentrated at the mean collar diameter de.If fe is the coefficient of collar friction,the torque required is Ffede Te= 2 (8-6) For large collars,the torque should probably be computed in a manner similar to that employed for disk clutches. Figure 8-7 (a)Normal thread force is increased because of angle a; b)thrust collar has frictional F/2 2 diameter d -Collar Nut 2a= Thread angle (a) (b)Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 8. Screws, Fasteners, and the Design of Nonpermanent Joints 406 © The McGraw−Hill Companies, 2008 Screws, Fasteners, and the Design of Nonpermanent Joints 403 Thread angle Collar Nut F cos F⁄ 2 (a) (b) F⁄ 2 F 2 = F⁄ 2 F⁄ 2 Figure 8–7 dc (a) Normal thread force is increased because of angle α; (b) thrust collar has frictional diameter dc. which, since thread friction has been eliminated, is the torque required only to raise the load. The efficiency is therefore e = T0 TR = Fl 2πTR (8–4) The preceding equations have been developed for square threads where the normal thread loads are parallel to the axis of the screw. In the case of Acme or other threads, the normal thread load is inclined to the axis because of the thread angle 2α and the lead angle λ. Since lead angles are small, this inclination can be neglected and only the effect of the thread angle (Fig. 8–7a) considered. The effect of the angle α is to increase the frictional force by the wedging action of the threads. Therefore the frictional terms in Eq. (8–1) must be divided by cos α. For raising the load, or for tightening a screw or bolt, this yields TR = Fdm 2 l + π f dm sec α πdm − f l sec α (8–5) In using Eq. (8–5), remember that it is an approximation because the effect of the lead angle has been neglected. For power screws, the Acme thread is not as efficient as the square thread, because of the additional friction due to the wedging action, but it is often preferred because it is easier to machine and permits the use of a split nut, which can be adjusted to take up for wear. Usually a third component of torque must be applied in power-screw applications. When the screw is loaded axially, a thrust or collar bearing must be employed between the rotating and stationary members in order to carry the axial component. Figure 8–7b shows a typical thrust collar in which the load is assumed to be concentrated at the mean collar diameter dc . If fc is the coefficient of collar friction, the torque required is Tc = F fcdc 2 (8–6) For large collars, the torque should probably be computed in a manner similar to that employed for disk clutches.�