正在加载图片...

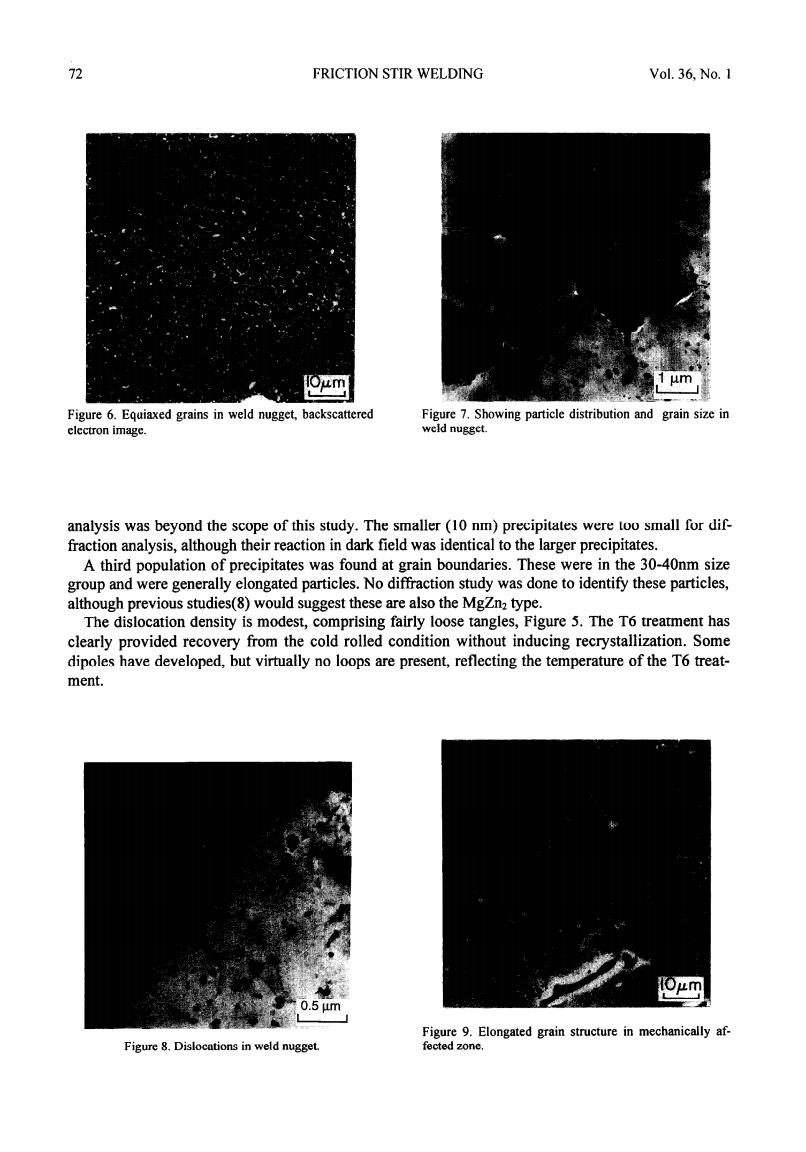

72 FRICTION STIR WELDING Vol.36,No.1 um I um Figure 6.Equiaxed grains in weld nugget,backscattered Figure 7.Showing particle distribution and grain size in clectron image. weld nugget. analysis was beyond the scope of this study.The smaller(10 nm)precipitates were too small for dif- fraction analysis,although their reaction in dark field was identical to the larger precipitates. A third population of precipitates was found at grain boundaries.These were in the 30-40nm size group and were generally elongated particles.No diffraction study was done to identify these particles, although previous studies(8)would suggest these are also the MgZna type. The dislocation density is modest,comprising fairly loose tangles,Figure 5.The T6 treatment has clearly provided recovery from the cold rolled condition without inducing recrystallization.Some dipoles have developed,but virtually no loops are present,reflecting the temperature of the T6 treat- ment. Oμ网 0.5m Figure 9.Elongated grain structure in mechanically af- Figure 8.Dislocations in weld nugget. fected zone.72 FRICTION STIR WELDING Vol. 36, No. 1 Figure 6. Equiaxed grains in weld nugget, backscattel electron image. .ed Figure 7. Showing particle distribution and grain size in weld nugget. analysis was beyond the scope of this study. The smaller (10 nm) precipitates were too small for diffraction analysis, although their reaction in dark field was identical to the larger precipitates. A third population of precipitates was found at grain boundaries. These were in the 30-40nm size group and were generally elongated particles. No diffraction study was done to identify these particles, although previous studies(S) would suggest these are also the MgZn2 type. The dislocation density is modest, comprising fairly loose tangles, Figure 5. The T6 treatment has clearly provided recovery from the cold rolled condition without inducing recrystallization. Some dipoles have developed, but virtually no loops are present, reflecting the temperature of the T6 treatment. Figure 8. Dislocations in weld nugget. Figure 9. Elongated grain structure in mechanically fected zone. af-