正在加载图片...

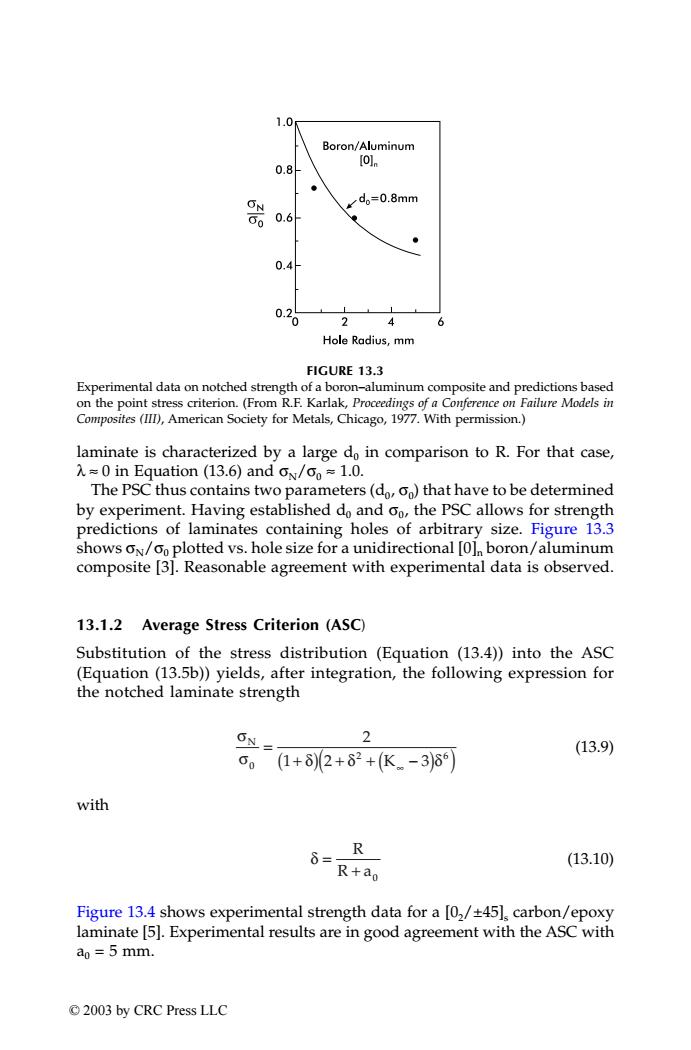

1.0 Boron/Aluminum [O] 0.8 ● ,d。=0.8mm 60 0.6 ● 0.4 02 2 4 6 Hole Radius,mm FIGURE 13.3 Experimental data on notched strength of a boron-aluminum composite and predictions based on the point stress criterion.(From R.F.Karlak,Proceedings of a Conference on Failure Models in Composites (III),American Society for Metals,Chicago,1977.With permission.) laminate is characterized by a large do in comparison to R.For that case, =0 in Equation (13.6)and ON/0o=1.0. The PSC thus contains two parameters(do,oo)that have to be determined by experiment.Having established do and oo,the PSC allows for strength predictions of laminates containing holes of arbitrary size.Figure 13.3 shows oN/0o plotted vs.hole size for a unidirectional [O]boron/aluminum composite [3].Reasonable agreement with experimental data is observed. 13.1.2 Average Stress Criterion (ASC) Substitution of the stress distribution (Equation (13.4))into the ASC (Equation (13.5b))yields,after integration,the following expression for the notched laminate strength 2 (13.9) 。(1+δ2+82+(K-3)8 with R 6= (13.10) R+ao Figure 13.4 shows experimental strength data for a [0,/+45]carbon/epoxy laminate [5].Experimental results are in good agreement with the ASC with ao =5 mm. ©2003 by CRC Press LLClaminate is characterized by a large d0 in comparison to R. For that case, λ ≈ 0 in Equation (13.6) and σN/σ0 ≈ 1.0. The PSC thus contains two parameters (d0, σ0) that have to be determined by experiment. Having established d0 and σ0, the PSC allows for strength predictions of laminates containing holes of arbitrary size. Figure 13.3 shows σN/σ0 plotted vs. hole size for a unidirectional [0]n boron/aluminum composite [3]. Reasonable agreement with experimental data is observed. 13.1.2 Average Stress Criterion (ASC) Substitution of the stress distribution (Equation (13.4)) into the ASC (Equation (13.5b)) yields, after integration, the following expression for the notched laminate strength (13.9) with (13.10) Figure 13.4 shows experimental strength data for a [02/±45]s carbon/epoxy laminate [5]. Experimental results are in good agreement with the ASC with a0 = 5 mm. FIGURE 13.3 Experimental data on notched strength of a boron–aluminum composite and predictions based on the point stress criterion. (From R.F. Karlak, Proceedings of a Conference on Failure Models in Composites (III), American Society for Metals, Chicago, 1977. With permission.) σ σ δδ δ N 0 K 2 6 2 12 3 = ( ) + ( ) ++ − ( ) ∞ δ = + R R a0 TX001_ch13_Frame Page 172 Saturday, September 21, 2002 5:07 AM © 2003 by CRC Press LLC