正在加载图片...

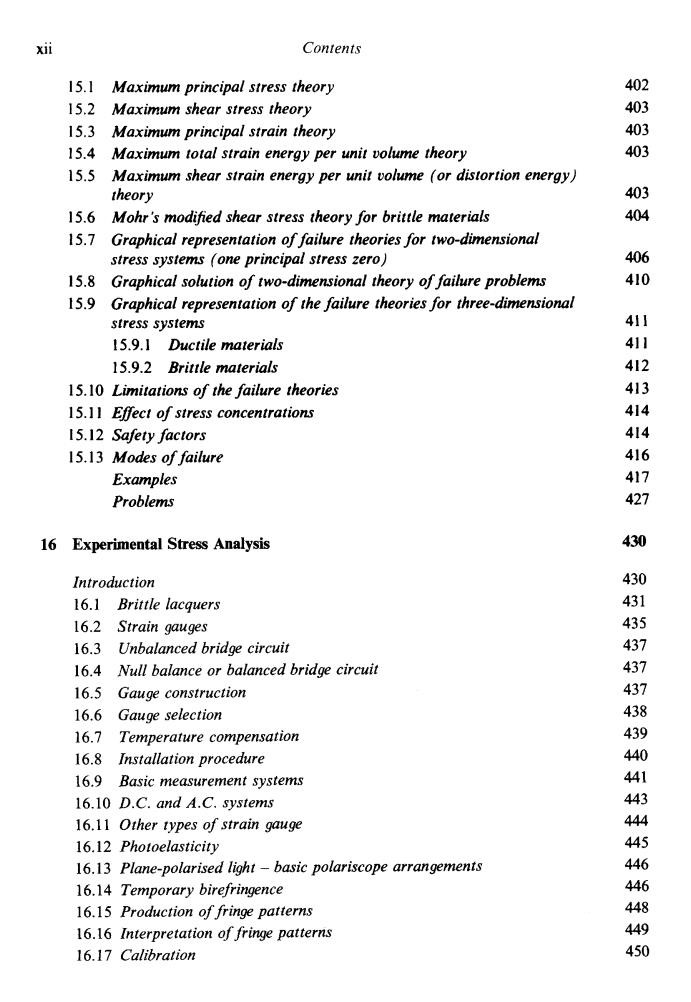

xii Contents 15.1 Maximum principal stress theory 402 15.2 Maximum shear stress theory 403 15.3 Maximum principal strain theory 403 15.4 Maximum total strain energy per unit volume theory 403 15.5 Maximum shear strain energy per unit volume (or distortion energy) theory 403 15.6 Mohr's modified shear stress theory for brittle materials 404 15.7 Graphical representation of failure theories for two-dimensional stress systems (one principal stress zero) 406 15.8 Graphical solution of two-dimensional theory of failure problems 410 15.9 Graphical representation of the failure theories for three-dimensional stress systems 41I 15.9.1 Ductile materials 411 15.9.2 Brittle materials 412 15.10 Limitations of the failure theories 413 15.11 Effect of stress concentrations 414 15.12 Safety factors 414 15.13 Modes of failure 416 Examples 417 Problems 427 16 Experimental Stress Analysis 430 Introduction 430 16.1 Brittle lacquers 431 16.2 Strain gauges 435 16.3 Unbalanced bridge circuit 437 16.4 Null balance or balanced bridge circuit 437 16.5 Gauge construction 437 16.6 Gauge selection 438 16.7 Temperature compensation 439 16.8 Installation procedure 440 16.9 Basic measurement systems 441 16.10 D.C.and A.C.systems 443 16.11 Other types of strain gauge 444 16.12 Photoelasticity 445 16.13 Plane-polarised light-basic polariscope arrangements 446 16.14 Temporary birefringence 446 16.15 Production of fringe patterns 448 16.16 Interpretation of fringe patterns 449 16.17 Calibration 450xii Contents 15.1 15.2 15.3 15.4 15.5 15.6 15.7 15.8 15.9 Maximum principal stress theory Maximum shear stress theory Maximum principal strain theory Maximum total strain energy per unit volume theory Maximum shear strain energy per unit volume (or distortion energy) theory Mohr 's modijied shear stress theory for brittle materials Graphical representation of failure theories for two-dimensional stress systems (one principal stress zero) Graphical solution of two-dimensional theory of failure problems Graphical representation of the failure theories for three-dimensional stress systems 15.9.1 Ductile materials 15.9.2 Brittle materials 15.10 Limitations of the failure theories 15.1 1 Eflect of stress concentrations 15.12 Safety factors 15.13 Modes of failure Examples Problems 16 Experimental Stress Analysis Introduction 16.1 Brittle lacquers 16.2 Strain gauges 16.3 Unbalanced bridge circuit 16.4 Null balance or balanced bridge circuit 16.5 Gauge construction 16.6 Gauge selection 16.7 Temperature compensation 16.8 Installation procedure 16.9 Basic measurement systems 16.10 D.C. and A.C. systems 16.11 Other types of strain gauge 16.12 Photoelasticity 16.13 Plane-polarised light - basic polariscope arrangements 16.14 Temporary birefringence 16.15 Production of fringe patterns 16.16 Interpretation of fringe patterns 16.17 Calibration 402 403 403 403 403 404 406 410 41 1 41 1 412 41 3 414 414 41 6 417 427 430 430 43 1 43 5 437 437 437 438 439 440 441 443 444 445 446 446 448 449 450