正在加载图片...

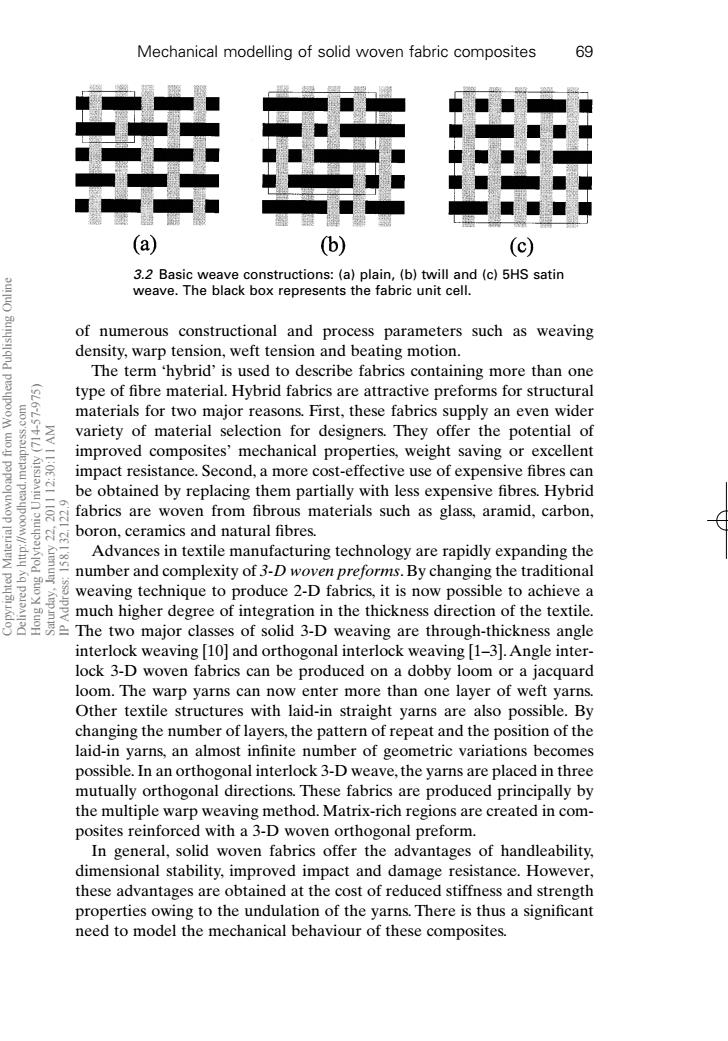

Mechanical modelling of solid woven fabric composites 69 (a) (b) (c) 3.2 Basic weave constructions:(a)plain,(b)twill and (c)5HS satin weave.The black box represents the fabric unit cell. of numerous constructional and process parameters such as weaving density,warp tension,weft tension and beating motion. The term 'hybrid'is used to describe fabrics containing more than one type of fibre material.Hybrid fabrics are attractive preforms for structural materials for two major reasons.First,these fabrics supply an even wider variety of material selection for designers.They offer the potential of improved composites'mechanical properties,weight saving or excellent impact resistance.Second,a more cost-effective use of expensive fibres can be obtained by replacing them partially with less expensive fibres.Hybrid fabrics are woven from fibrous materials such as glass,aramid,carbon, boron,ceramics and natural fibres. Advances in textile manufacturing technology are rapidly expanding the number and complexity of 3-D woven preforms.By changing the traditional weaving technique to produce 2-D fabrics,it is now possible to achieve a s much higher degree of integration in the thickness direction of the textile. The two major classes of solid 3-D weaving are through-thickness angle interlock weaving [10]and orthogonal interlock weaving [1-3].Angle inter- lock 3-D woven fabrics can be produced on a dobby loom or a jacquard loom.The warp yarns can now enter more than one layer of weft yarns. Other textile structures with laid-in straight yarns are also possible.By changing the number of layers,the pattern of repeat and the position of the laid-in yarns,an almost infinite number of geometric variations becomes possible.In an orthogonal interlock 3-D weave,the yarns are placed in three mutually orthogonal directions.These fabrics are produced principally by the multiple warp weaving method.Matrix-rich regions are created in com- posites reinforced with a 3-D woven orthogonal preform. In general,solid woven fabrics offer the advantages of handleability, dimensional stability,improved impact and damage resistance.However, these advantages are obtained at the cost of reduced stiffness and strength properties owing to the undulation of the yarns.There is thus a significant need to model the mechanical behaviour of these composites.of numerous constructional and process parameters such as weaving density, warp tension, weft tension and beating motion. The term ‘hybrid’ is used to describe fabrics containing more than one type of fibre material. Hybrid fabrics are attractive preforms for structural materials for two major reasons. First, these fabrics supply an even wider variety of material selection for designers. They offer the potential of improved composites’ mechanical properties, weight saving or excellent impact resistance. Second, a more cost-effective use of expensive fibres can be obtained by replacing them partially with less expensive fibres. Hybrid fabrics are woven from fibrous materials such as glass, aramid, carbon, boron, ceramics and natural fibres. Advances in textile manufacturing technology are rapidly expanding the number and complexity of 3-D woven preforms. By changing the traditional weaving technique to produce 2-D fabrics, it is now possible to achieve a much higher degree of integration in the thickness direction of the textile. The two major classes of solid 3-D weaving are through-thickness angle interlock weaving [10] and orthogonal interlock weaving [1–3].Angle interlock 3-D woven fabrics can be produced on a dobby loom or a jacquard loom. The warp yarns can now enter more than one layer of weft yarns. Other textile structures with laid-in straight yarns are also possible. By changing the number of layers, the pattern of repeat and the position of the laid-in yarns, an almost infinite number of geometric variations becomes possible. In an orthogonal interlock 3-D weave, the yarns are placed in three mutually orthogonal directions. These fabrics are produced principally by the multiple warp weaving method. Matrix-rich regions are created in composites reinforced with a 3-D woven orthogonal preform. In general, solid woven fabrics offer the advantages of handleability, dimensional stability, improved impact and damage resistance. However, these advantages are obtained at the cost of reduced stiffness and strength properties owing to the undulation of the yarns. There is thus a significant need to model the mechanical behaviour of these composites. Mechanical modelling of solid woven fabric composites 69 3.2 Basic weave constructions: (a) plain, (b) twill and (c) 5HS satin weave. The black box represents the fabric unit cell. RIC3 7/10/99 7:37 PM Page 69 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:30:11 AM IP Address: 158.132.122.9