正在加载图片...

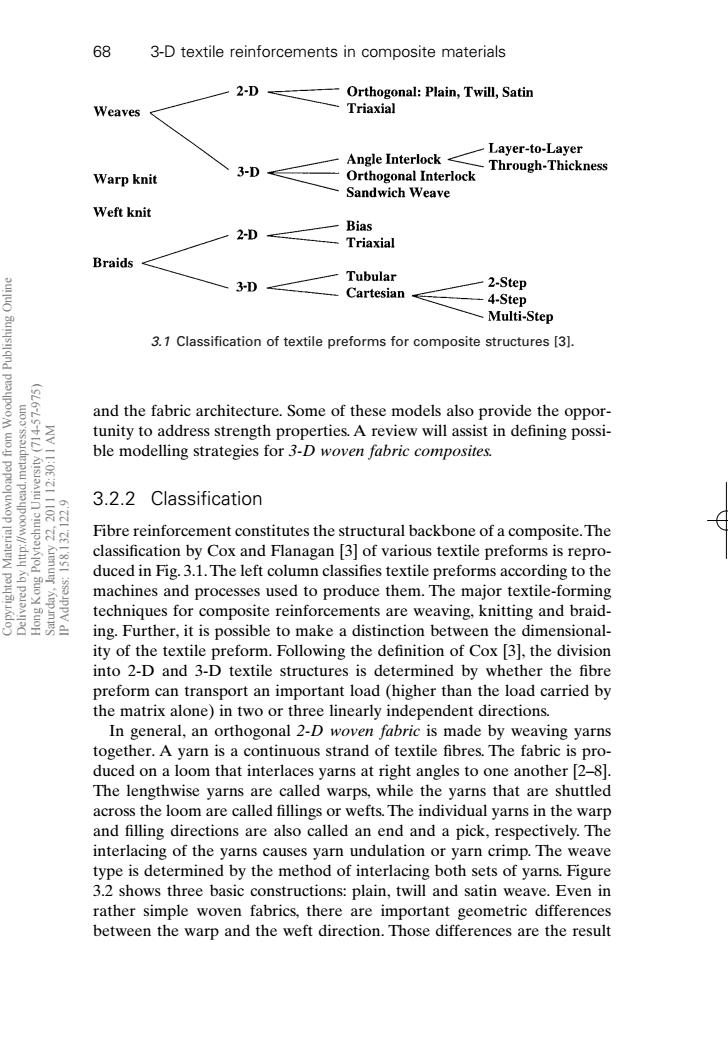

68 3-D textile reinforcements in composite materials 2-D Orthogonal:Plain,Twill,Satin Weaves Triaxial Layer-to-Layer Angle Interlock 3-D Through-Thickness Warp knit Orthogonal Interlock Sandwich Weave Weft knit 2-D Bias Triaxial Braids Tubular 3-D 2-Step Cartesian 4-Step Multi-Step 3.1 Classification of textile preforms for composite structures [31. and the fabric architecture.Some of these models also provide the oppor- WV:OS tunity to address strength properties.A review will assist in defining possi- ble modelling strategies for 3-D woven fabric composites. 2102 3.2.2 Classification Fibre reinforcement constitutes the structural backbone of a composite.The classification by Cox and Flanagan 3 of various textile preforms is repro- duced in Fig.3.1.The left column classifies textile preforms according to the machines and processes used to produce them.The major textile-forming techniques for composite reinforcements are weaving,knitting and braid- ing.Further,it is possible to make a distinction between the dimensional- ity of the textile preform.Following the definition of Cox [3],the division into 2-D and 3-D textile structures is determined by whether the fibre preform can transport an important load (higher than the load carried by the matrix alone)in two or three linearly independent directions. In general,an orthogonal 2-D woven fabric is made by weaving yarns together.A yarn is a continuous strand of textile fibres.The fabric is pro- duced on a loom that interlaces yarns at right angles to one another [2-8]. The lengthwise yarns are called warps,while the yarns that are shuttled across the loom are called fillings or wefts.The individual yarns in the warp and filling directions are also called an end and a pick,respectively.The interlacing of the yarns causes yarn undulation or yarn crimp.The weave type is determined by the method of interlacing both sets of yarns.Figure 3.2 shows three basic constructions:plain,twill and satin weave.Even in rather simple woven fabrics,there are important geometric differences between the warp and the weft direction.Those differences are the resultand the fabric architecture. Some of these models also provide the opportunity to address strength properties. A review will assist in defining possible modelling strategies for 3-D woven fabric composites. 3.2.2 Classification Fibre reinforcement constitutes the structural backbone of a composite.The classification by Cox and Flanagan [3] of various textile preforms is reproduced in Fig. 3.1.The left column classifies textile preforms according to the machines and processes used to produce them. The major textile-forming techniques for composite reinforcements are weaving, knitting and braiding. Further, it is possible to make a distinction between the dimensionality of the textile preform. Following the definition of Cox [3], the division into 2-D and 3-D textile structures is determined by whether the fibre preform can transport an important load (higher than the load carried by the matrix alone) in two or three linearly independent directions. In general, an orthogonal 2-D woven fabric is made by weaving yarns together. A yarn is a continuous strand of textile fibres. The fabric is produced on a loom that interlaces yarns at right angles to one another [2–8]. The lengthwise yarns are called warps, while the yarns that are shuttled across the loom are called fillings or wefts. The individual yarns in the warp and filling directions are also called an end and a pick, respectively. The interlacing of the yarns causes yarn undulation or yarn crimp. The weave type is determined by the method of interlacing both sets of yarns. Figure 3.2 shows three basic constructions: plain, twill and satin weave. Even in rather simple woven fabrics, there are important geometric differences between the warp and the weft direction. Those differences are the result 68 3-D textile reinforcements in composite materials 3.1 Classification of textile preforms for composite structures [3]. RIC3 7/10/99 7:37 PM Page 68 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:30:11 AM IP Address: 158.132.122.9