正在加载图片...

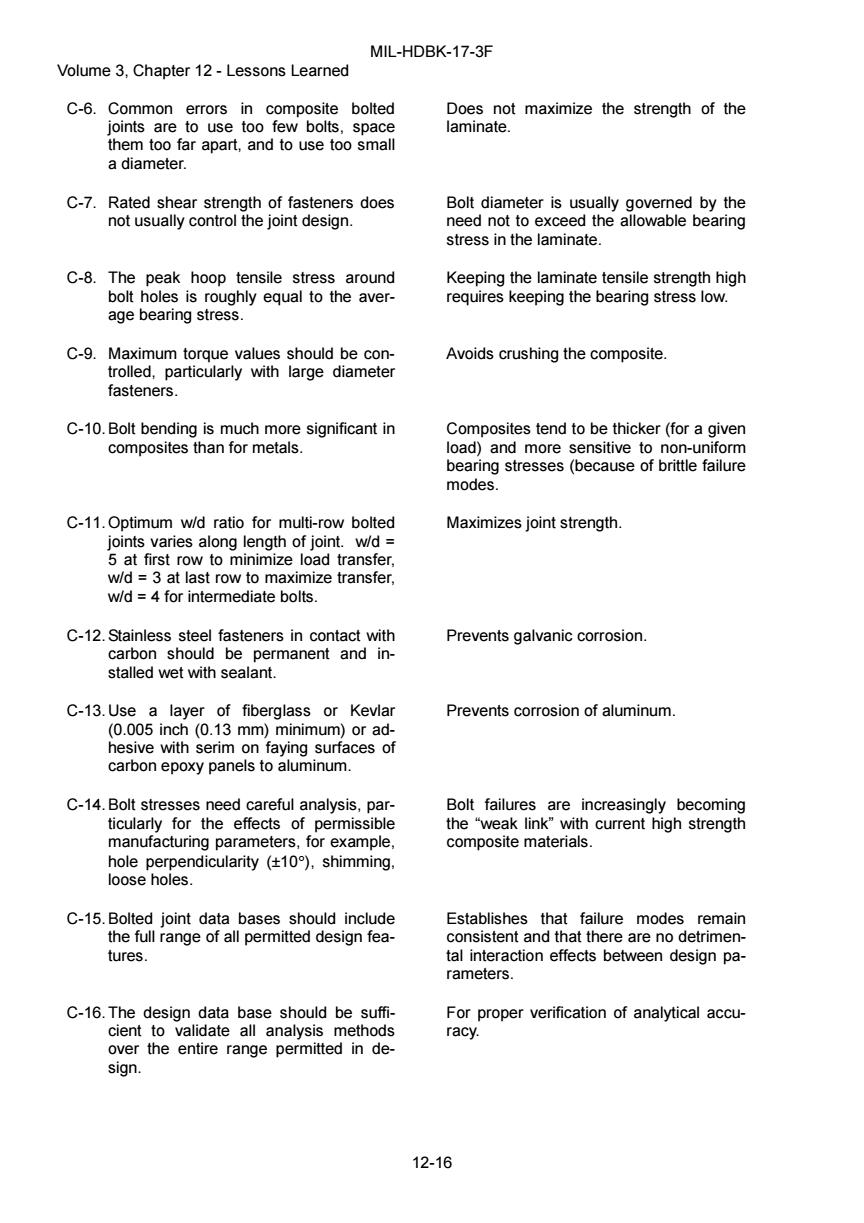

MIL-HDBK-17-3F Volume 3.Chapter 12-Lessons Learned C-6.Common errors in composite bolted Does not maximize the strength of the joints are to use too few bolts,space laminate. them too far apart,and to use too small a diameter. C-7.Rated shear strength of fasteners does Bolt diameter is usually governed by the not usually control the joint design. need not to exceed the allowable bearing stress in the laminate. C-8.The peak hoop tensile stress around Keeping the laminate tensile strength high bolt holes is roughly equal to the aver- requires keeping the bearing stress low. age bearing stress. C-9.Maximum torque values should be con- Avoids crushing the composite trolled,particularly with large diameter fasteners. C-10.Bolt bending is much more significant in Composites tend to be thicker(for a given composites than for metals. load)and more sensitive to non-uniform bearing stresses(because of brittle failure modes. C-11.Optimum w/d ratio for multi-row bolted Maximizes joint strength. joints varies along length of joint.w/d 5 at first row to minimize load transfer. w/d 3 at last row to maximize transfer. w/d =4 for intermediate bolts. C-12.Stainless steel fasteners in contact with Prevents galvanic corrosion. carbon should be permanent and in- stalled wet with sealant. C-13.Use a layer of fiberglass or Kevlar Prevents corrosion of aluminum. (0.005 inch(0.13 mm)minimum)or ad- hesive with serim on faying surfaces of carbon epoxy panels to aluminum. C-14.Bolt stresses need careful analysis,par- Bolt failures are increasingly becoming ticularly for the effects of permissible the“weak link”with current high strength manufacturing parameters,for example, composite materials. hole perpendicularity (+10),shimming. loose holes. C-15.Bolted joint data bases should include Establishes that failure modes remain the full range of all permitted design fea- consistent and that there are no detrimen- tures. tal interaction effects between design pa- rameters. C-16.The design data base should be suffi- For proper verification of analytical accu- cient to validate all analysis methods racy. over the entire range permitted in de- sign. 12-16MIL-HDBK-17-3F Volume 3, Chapter 12 - Lessons Learned 12-16 C-6. Common errors in composite bolted joints are to use too few bolts, space them too far apart, and to use too small a diameter. Does not maximize the strength of the laminate. C-7. Rated shear strength of fasteners does not usually control the joint design. Bolt diameter is usually governed by the need not to exceed the allowable bearing stress in the laminate. C-8. The peak hoop tensile stress around bolt holes is roughly equal to the average bearing stress. Keeping the laminate tensile strength high requires keeping the bearing stress low. C-9. Maximum torque values should be controlled, particularly with large diameter fasteners. Avoids crushing the composite. C-10. Bolt bending is much more significant in composites than for metals. Composites tend to be thicker (for a given load) and more sensitive to non-uniform bearing stresses (because of brittle failure modes. C-11. Optimum w/d ratio for multi-row bolted joints varies along length of joint. w/d = 5 at first row to minimize load transfer, w/d = 3 at last row to maximize transfer, w/d = 4 for intermediate bolts. Maximizes joint strength. C-12. Stainless steel fasteners in contact with carbon should be permanent and installed wet with sealant. Prevents galvanic corrosion. C-13. Use a layer of fiberglass or Kevlar (0.005 inch (0.13 mm) minimum) or adhesive with serim on faying surfaces of carbon epoxy panels to aluminum. Prevents corrosion of aluminum. C-14. Bolt stresses need careful analysis, particularly for the effects of permissible manufacturing parameters, for example, hole perpendicularity (±10°), shimming, loose holes. Bolt failures are increasingly becoming the “weak link” with current high strength composite materials. C-15. Bolted joint data bases should include the full range of all permitted design features. Establishes that failure modes remain consistent and that there are no detrimental interaction effects between design parameters. C-16. The design data base should be sufficient to validate all analysis methods over the entire range permitted in design. For proper verification of analytical accuracy