正在加载图片...

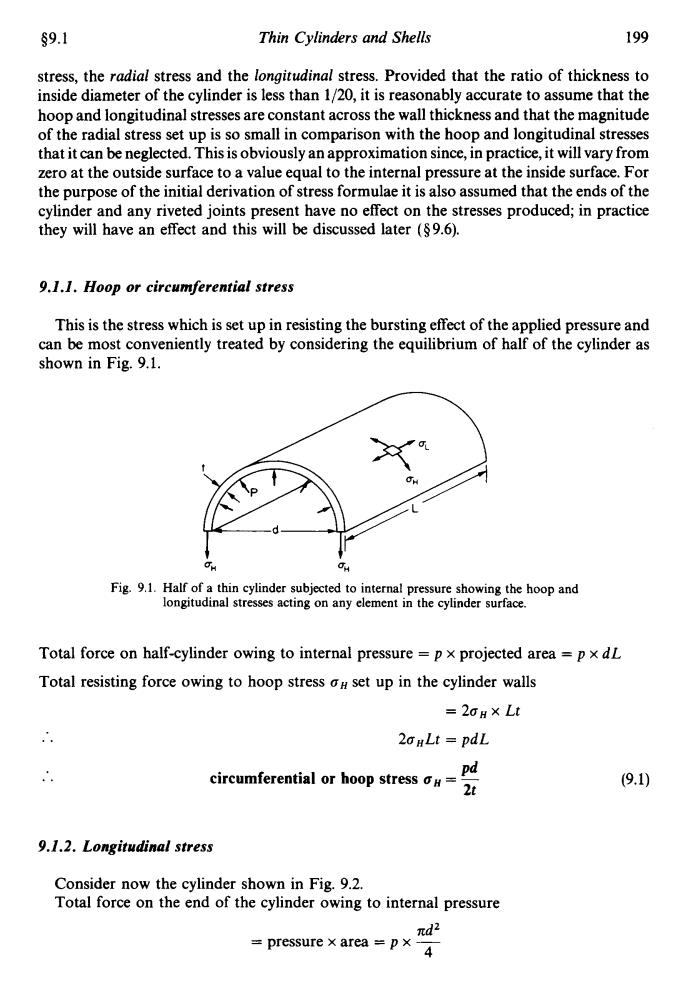

s9.1 Thin Cylinders and Shells 199 stress,the radial stress and the longitudinal stress.Provided that the ratio of thickness to inside diameter of the cylinder is less than 1/20,it is reasonably accurate to assume that the hoop and longitudinal stresses are constant across the wall thickness and that the magnitude of the radial stress set up is so small in comparison with the hoop and longitudinal stresses that it can be neglected.This is obviously an approximation since,in practice,it will vary from zero at the outside surface to a value equal to the internal pressure at the inside surface.For the purpose of the initial derivation of stress formulae it is also assumed that the ends of the cylinder and any riveted joints present have no effect on the stresses produced;in practice they will have an effect and this will be discussed later ($9.6). 9.1.1.Hoop or circumferential stress This is the stress which is set up in resisting the bursting effect of the applied pressure and can be most conveniently treated by considering the equilibrium of half of the cylinder as shown in Fig.9.1. CH 60 Fig.9.1.Half of a thin cylinder subjected to internal pressure showing the hoop and longitudinal stresses acting on any element in the cylinder surface. Total force on half-cylinder owing to internal pressure p x projected area =p x dL Total resisting force owing to hoop stress aH set up in the cylinder walls =2oH×Lt 20HLt pdL circumferential or hoop stress o#= pd 2t (9.1) 9.1.2.Longitudinal stress Consider now the cylinder shown in Fig.9.2. Total force on the end of the cylinder owing to internal pressure nd2 pressure x area=px459.1 Thin Cylinders and Shells 199 stress, the radial stress and the longitudinal stress. Provided that the ratio of thickness to inside diameter of the cylinder is less than 1/20, it is reasonably accurate to assume that the hoop and longitudinal stresses are constant across the wall thickness and that the magnitude of the radial stress set up is so small in comparison with the hoop and longitudinal stresses that it can be neglected. This is obviously an approximation since, in practice, it will vary from zero at the outside surface to a value equal to the internal pressure at the inside surface. For the purpose of the initial derivation of stress formulae it is also assumed that the ends of the cylinder and any riveted joints present have no effect on the stresses produced; in practice they will have an effect and this will be discussed later (5 9.6). 9.1.1. Hoop or circumferential stress This is the stress which is set up in resisting the bursting effect of the applied pressure and can be most conveniently treated by considering the equilibrium of half of the cylinder as shown in Fig. 9.1. QU Qn Fig. 9.1. Half of a thin cylinder subjected to internal pressure showing the hoop and longitudinal stresses acting on any element in the cylinder surface. Total force on half-cylinder owing to internal pressure = p x projected area = p x dL Total resisting force owing to hoop stress on set up in the cylinder walls = 2oH x Lt .. 2aHLt = pdL Pd .. circumferential or hoop stress uH = - 2t 9.1.2. Longitudinal stress Consider now the cylinder shown in Fig. 9.2. Total force on the end of the cylinder owing to internal pressure nd2 = pressure x area = p x ~ 4