正在加载图片...

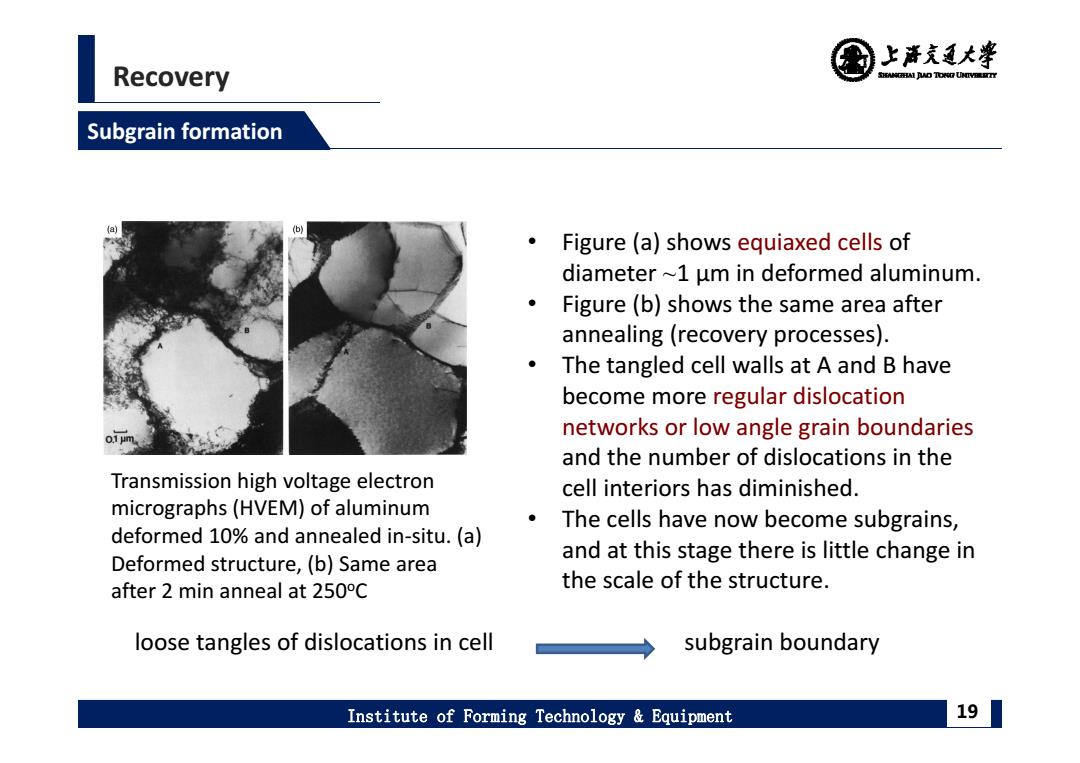

上清充通大¥ Recovery SHEAMGHAI DUD TONO UHTVEREETTY Subgrain formation Figure(a)shows equiaxed cells of diameter ~1 um in deformed aluminum. Figure(b)shows the same area after annealing(recovery processes). The tangled cell walls at A and B have become more regular dislocation networks or low angle grain boundaries and the number of dislocations in the Transmission high voltage electron cell interiors has diminished. micrographs(HVEM)of aluminum The cells have now become subgrains, deformed 10%and annealed in-situ.(a) and at this stage there is little change in Deformed structure,(b)Same area after 2 min anneal at 250C the scale of the structure. loose tangles of dislocations in cell subgrain boundary Institute of Forming Technology Equipment 19Recovery Institute of Forming Technology & Equipment 19 Subgrain formation Transmission high voltage electron micrographs (HVEM) of aluminum deformed 10% and annealed in‐situ. (a) Deformed structure, (b) Same area after 2 min anneal at 250oC • Figure (a) shows equiaxed cells of diameter ~1 μm in deformed aluminum. • Figure (b) shows the same area after annealing (recovery processes). • The tangled cell walls at A and B have become more regular dislocation networks or low angle grain boundaries and the number of dislocations in the cell interiors has diminished. • The cells have now become subgrains, and at this stage there is little change in the scale of the structure. loose tangles of dislocations in cell subgrain boundary