正在加载图片...

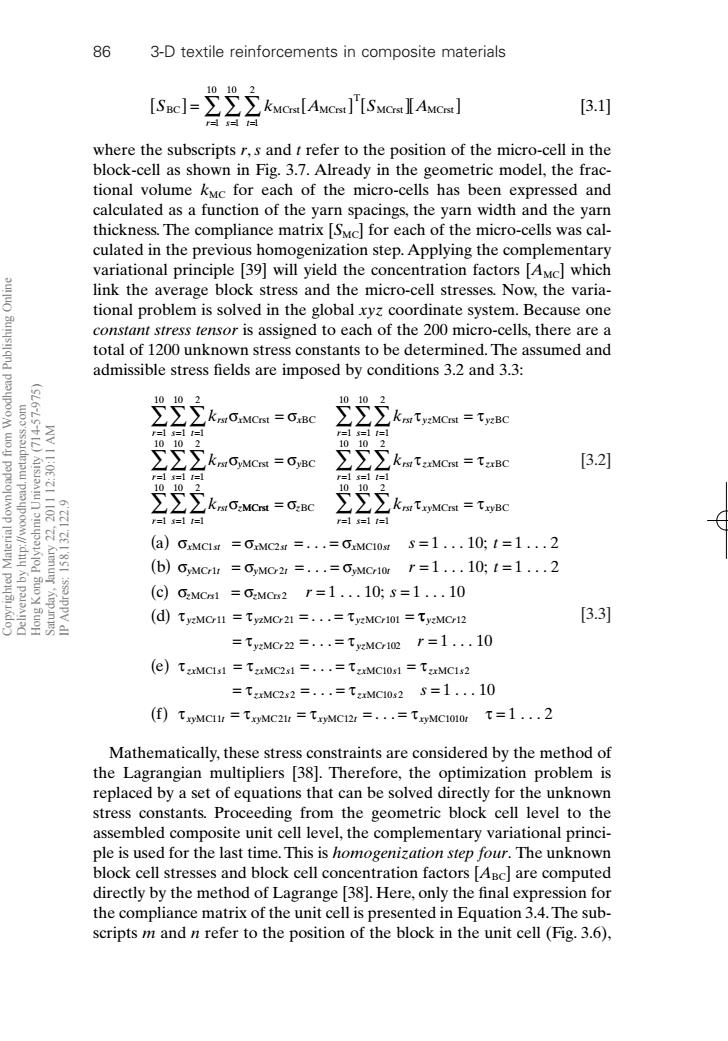

86 3-D textile reinforcements in composite materials 1010 [Sc]=∑∑∑MC[AMcmt]'[CAMcnt] [3.1] where the subscripts r,s and t refer to the position of the micro-cell in the block-cell as shown in Fig.3.7.Already in the geometric model,the frac- tional volume kMc for each of the micro-cells has been expressed and calculated as a function of the yarn spacings,the yarn width and the yarn thickness.The compliance matrix [SMc]for each of the micro-cells was cal- culated in the previous homogenization step.Applying the complementary variational principle [39]will yield the concentration factors [AMc]which link the average block stress and the micro-cell stresses.Now,the varia- tional problem is solved in the global xyz coordinate system.Because one constant stress tensor is assigned to each of the 200 micro-cells,there are a total of 1200 unknown stress constants to be determined.The assumed and admissible stress fields are imposed by conditions 3.2 and 3.3: 10102 10102 ∑∑∑kMCt=oBC ∑∑∑nyMCmt=t:Bc r=l=1=1 r=1x=11=1 10102 10102 2∑kNom=oc ∑∑∑KrMCn=taBc 3.2] r=1x=1I=1 r=1x=1l=1 Muautunanuainioaauoystift 222ko=0K 10102 ∑∑2 wC=tnBc r=1x=1=1 r=1x=1t=1 6'ZZI ZEI'8SI :dl (a)GMcist =GMc2s =...=OMcIos $=1...10;1=1...2 (b)OMC=CMo21=..=CMC1gT=1..101=1..2 (CC2Mcn1=O2MOs2r=1..10;S=1..10 (d)TyMCr1=TzMC21=.·.=TyzMCr01=TyzMCr12 [3.3] =TyMC2=..=TMo102r=1..10 (e)TxMC11=TaMC21=.·.=TaMC10s1=TxMC1s2 =TzMc22=..=T2xMc10s2S=1..10 (f)toMci=tomcau =txMci2r =...taMciolor t=1...2 Mathematically,these stress constraints are considered by the method of the Lagrangian multipliers [38].Therefore,the optimization problem is replaced by a set of equations that can be solved directly for the unknown stress constants.Proceeding from the geometric block cell level to the assembled composite unit cell level,the complementary variational princi- ple is used for the last time.This is homogenization step four.The unknown block cell stresses and block cell concentration factors [Asc]are computed directly by the method of Lagrange [38].Here,only the final expression for the compliance matrix of the unit cell is presented in Equation 3.4.The sub- scripts m and n refer to the position of the block in the unit cell (Fig.3.6),[3.1] where the subscripts r, s and t refer to the position of the micro-cell in the block-cell as shown in Fig. 3.7. Already in the geometric model, the fractional volume kMC for each of the micro-cells has been expressed and calculated as a function of the yarn spacings, the yarn width and the yarn thickness. The compliance matrix [SMC] for each of the micro-cells was calculated in the previous homogenization step. Applying the complementary variational principle [39] will yield the concentration factors [AMC] which link the average block stress and the micro-cell stresses. Now, the variational problem is solved in the global xyz coordinate system. Because one constant stress tensor is assigned to each of the 200 micro-cells, there are a total of 1200 unknown stress constants to be determined. The assumed and admissible stress fields are imposed by conditions 3.2 and 3.3: Mathematically, these stress constraints are considered by the method of the Lagrangian multipliers [38]. Therefore, the optimization problem is replaced by a set of equations that can be solved directly for the unknown stress constants. Proceeding from the geometric block cell level to the assembled composite unit cell level, the complementary variational principle is used for the last time. This is homogenization step four. The unknown block cell stresses and block cell concentration factors [ABC] are computed directly by the method of Lagrange [38]. Here, only the final expression for the compliance matrix of the unit cell is presented in Equation 3.4. The subscripts m and n refer to the position of the block in the unit cell (Fig. 3.6), a . . . . . 10; . . . 2 b . . . . . 10; . . . 2 c . . . 10; . . . 10 d . . MC1 MC2 MC10 MC 1 MC 2 MC 10 MC 1 MCr MC 11 zMC 21 MC 10 ( ) = == = = ( ) = == = = ( ) === ( ) = == = ss s ss s s s tt t x st x st x st y rt y rt y r t z rs z s yz r y r yz r s t r t r s . . . 1 1 1 1 2 1 1 1 t t t tt t t t t ttt t t yz r yz r yz r zx s zx s zx s zx s zx s zx s xy t xy t xy t xy t r s MC 12 MC MC MC1 1 MC2 MC10 MC MC2 MC10 MC11 MC MC MC . . . . . 10 e . . . . . . . 10 f . . . . . 2 = == = ( ) = == = = == = ( ) = = == = 22 102 1 1 12 2 2 21 12 1010 1 1 1 . . . . rst rst x x rst rst yz yz rst rst y y rst rst zx zx rst rst z k k k k k === === === === === ÂÂÂ ÂÂÂ ÂÂÂ ÂÂÂ ÂÂÂ = = = = 1 10 1 10 1 2 1 10 1 10 1 2 1 10 1 10 1 2 1 10 1 10 1 2 1 10 1 10 1 2 ss t t ss t t s MCrst BC MCrst BC MCrst BC MCrst BC MCrst BC MCrst BC = = === s tt z ÂÂÂ rst krst xy xy 1 10 1 10 1 2 S kA S A rst BC MCrst MCrst T [ ] = [ ] [ ][ ] MCrst MCrst === ÂÂÂ 1 10 1 10 1 2 86 3-D textile reinforcements in composite materials [3.2] [3.3] RIC3 7/10/99 7:37 PM Page 86 Copyrighted Material downloaded from Woodhead Publishing Online Delivered by http://woodhead.metapress.com Hong Kong Polytechnic University (714-57-975) Saturday, January 22, 2011 12:30:11 AM IP Address: 158.132.122.9