正在加载图片...

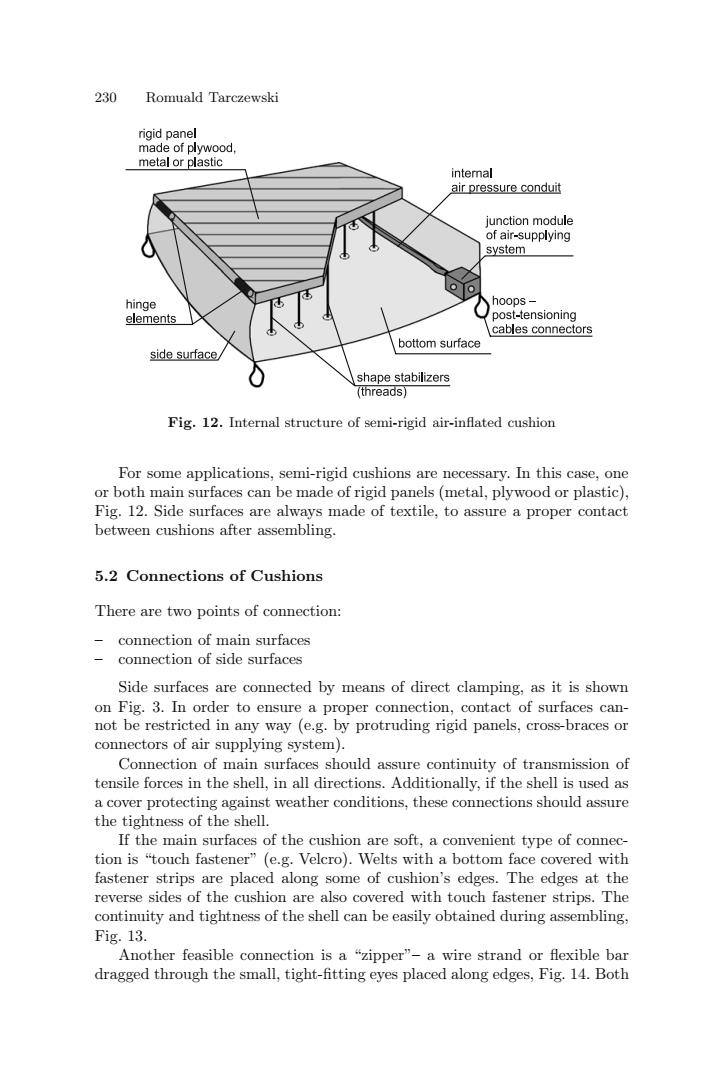

230 Romuald Tarczewski rigid panel made of plywood. metal or plastic intemal air pressure conduit junction module of air-supplying system hinge hoops- elements post-tensioning cables connectors bottom surface side surface shape stabilizers (threads) Fig.12.Internal structure of semi-rigid air-inflated cushion For some applications,semi-rigid cushions are necessary.In this case,one or both main surfaces can be made of rigid panels(metal,plywood or plastic), Fig.12.Side surfaces are always made of textile,to assure a proper contact between cushions after assembling. 5.2 Connections of Cushions There are two points of connection: connection of main surfaces connection of side surfaces Side surfaces are connected by means of direct clamping,as it is shown on Fig.3.In order to ensure a proper connection,contact of surfaces can- not be restricted in any way (e.g.by protruding rigid panels,cross-braces or connectors of air supplying system). Connection of main surfaces should assure continuity of transmission of tensile forces in the shell,in all directions.Additionally,if the shell is used as a cover protecting against weather conditions,these connections should assure the tightness of the shell. If the main surfaces of the cushion are soft,a convenient type of connec- tion is "touch fastener"(e.g.Velcro).Welts with a bottom face covered with fastener strips are placed along some of cushion's edges.The edges at the reverse sides of the cushion are also covered with touch fastener strips.The continuity and tightness of the shell can be easily obtained during assembling, Fig.13. Another feasible connection is a "zipper"-a wire strand or flexible bar dragged through the small,tight-fitting eyes placed along edges,Fig.14.Both230 Romuald Tarczewski For some applications, semi-rigid cushions are necessary. In this case, one or both main surfaces can be made of rigid panels (metal, plywood or plastic), Fig. 12. Side surfaces are always made of textile, to assure a proper contact between cushions after assembling. 5.2 Connections of Cushions There are two points of connection: – connection of main surfaces – connection of side surfaces Side surfaces are connected by means of direct clamping, as it is shown on Fig. 3. In order to ensure a proper connection, contact of surfaces cannot be restricted in any way (e.g. by protruding rigid panels, cross-braces or connectors of air supplying system). Connection of main surfaces should assure continuity of transmission of tensile forces in the shell, in all directions. Additionally, if the shell is used as a cover protecting against weather conditions, these connections should assure the tightness of the shell. If the main surfaces of the cushion are soft, a convenient type of connection is “touch fastener” (e.g. Velcro). Welts with a bottom face covered with fastener strips are placed along some of cushion’s edges. The edges at the reverse sides of the cushion are also covered with touch fastener strips. The continuity and tightness of the shell can be easily obtained during assembling, Fig. 13. Another feasible connection is a “zipper”– a wire strand or flexible bar dragged through the small, tight-fitting eyes placed along edges, Fig. 14. Both Fig. 12. Internal structure of semi-rigid air-inflated cushion