正在加载图片...

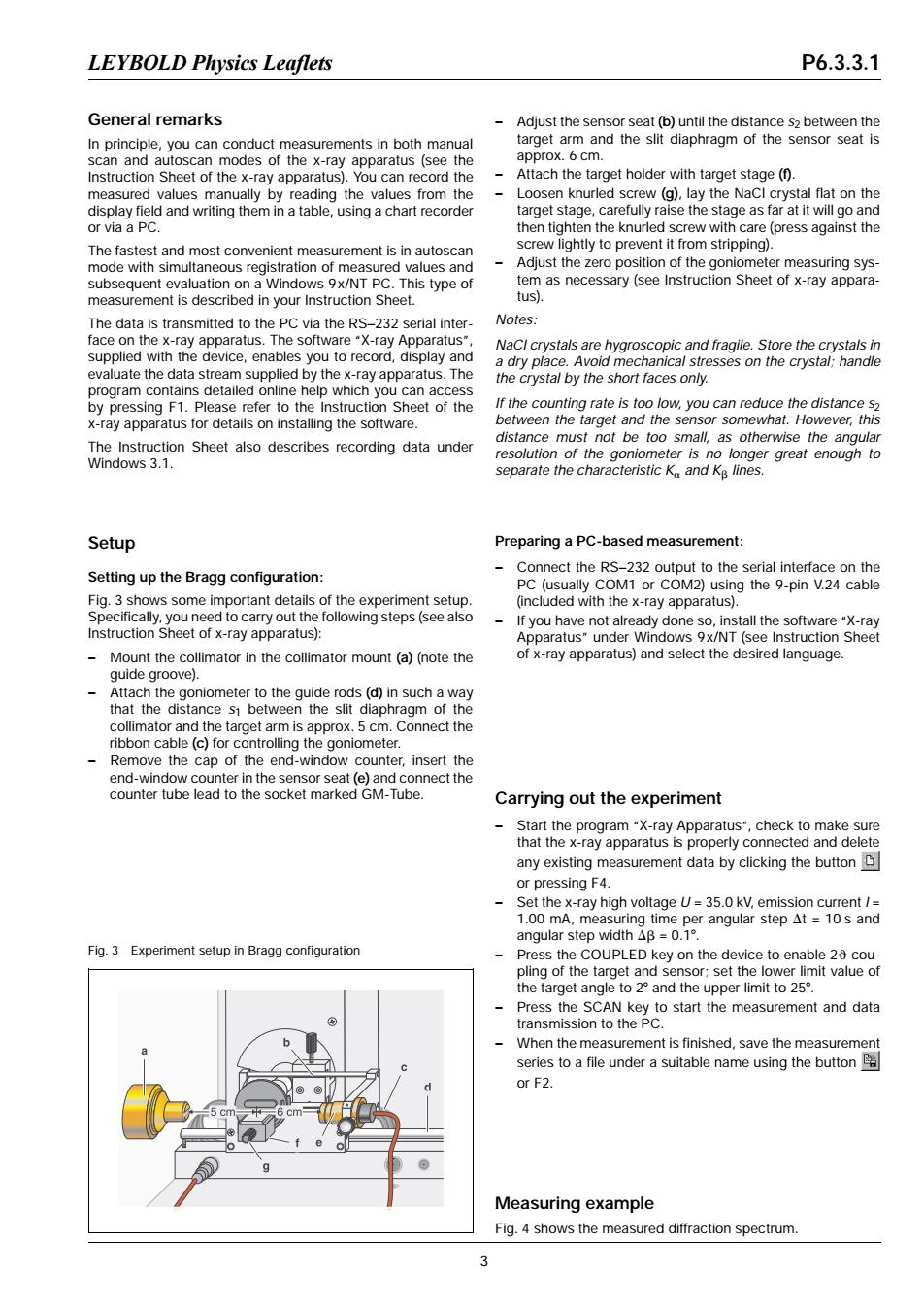

LEYBOLD Physics Leaflets P6.3.3.1 General remarks Adjust the sensor seat(b)until the distance s2 between the In principle,you can conduct measurements in both manual target arm and the slit diaphragm of the sensor seat is scan and autoscan modes of the x-ray apparatus (see the approx.6 cm. Instruction Sheet of the x-ray apparatus).You can record the Attach the target holder with target stage (f). measured values manually by reading the values from the Loosen knurled screw (g).lay the NaCI crystal flat on the display field and writing them in a table,using a chart recorder target stage,carefully raise the stage as far at it will go and or via a PC. then tighten the knurled screw with care(press against the The fastest and most convenient measurement is in autoscan screw lightly to prevent it from stripping). mode with simultaneous registration of measured values and Adjust the zero position of the goniometer measuring sys- subsequent evaluation on a Windows 9x/NT PC.This type of tem as necessary(see Instruction Sheet of x-ray appara- measurement is described in your Instruction Sheet. tus). The data is transmitted to the PC via the RS-232 serial inter- Notes: face on the x-ray apparatus.The software"X-ray Apparatus" NaCI crystals are hygroscopic and fragile.Store the crystals in supplied with the device,enables you to record,display and a dry place.Avoid mechanical stresses on the crystal;handle evaluate the data stream supplied by the x-ray apparatus.The the crystal by the short faces only. program contains detailed online help which you can access by pressing F1.Please refer to the Instruction Sheet of the If the counting rate is too low,you can reduce the distance s x-ray apparatus for details on installing the software. between the target and the sensor somewhat.However,this distance must not be too small,as otherwise the angular The Instruction Sheet also describes recording data under resolution of the goniometer is no longer great enough to Windows 3.1. separate the characteristic K and Kg lines. Setup Preparing a PC-based measurement: Setting up the Bragg configuration: Connect the RS-232 output to the serial interface on the PC (usually COM1 or COM2)using the 9-pin V.24 cable Fig.3 shows some important details of the experiment setup. (included with the x-ray apparatus). Specifically,you need to carry out the following steps (see also If you have not already done so,install the software"X-ray Instruction Sheet of x-ray apparatus): Apparatus"under Windows 9x/NT (see Instruction Sheet Mount the collimator in the collimator mount(a)(note the of x-ray apparatus)and select the desired language. guide groove). Attach the goniometer to the guide rods(d)in such a way that the distance s1 between the slit diaphragm of the collimator and the target arm is approx.5 cm.Connect the ribbon cable (c)for controlling the goniometer. Remove the cap of the end-window counter,insert the end-window counter in the sensor seat (e)and connect the counter tube lead to the socket marked GM-Tube. Carrying out the experiment Start the program"X-ray Apparatus",check to make sure that the x-ray apparatus is properly connected and delete any existing measurement data by clicking the button or pressing F4. Set the x-ray high voltage U=35.0 kV,emission current / 1.00 mA,measuring time per angular step At =10s and angular step width△B=o.1°. Fig.3 Experiment setup in Bragg configuration Press the COUPLED key on the device to enable 25 cou- pling of the target and sensor;set the lower limit value of the target angle to 2 and the upper limit to 25. Press the SCAN key to start the measurement and data transmission to the PC. When the measurement is finished,save the measurement series to a file under a suitable name using the button or F2. Measuring example Fig.4 shows the measured diffraction spectrum 3General remarks In principle, you can conduct measurements in both manual scan and autoscan modes of the x-ray apparatus (see the Instruction Sheet of the x-ray apparatus). You can record the measured values manually by reading the values from the display field and writing them in a table, using a chart recorder or via a PC. The fastest and most convenient measurement is in autoscan mode with simultaneous registration of measured values and subsequent evaluation on a Windows 9x/NT PC. This type of measurement is described in your Instruction Sheet. The data is transmitted to the PC via the RS−232 serial interface on the x-ray apparatus. The software “X-ray Apparatus”, supplied with the device, enables you to record, display and evaluate the data stream supplied by the x-ray apparatus. The program contains detailed online help which you can access by pressing F1. Please refer to the Instruction Sheet of the x-ray apparatus for details on installing the software. The Instruction Sheet also describes recording data under Windows 3.1. Setup Setting up the Bragg configuration: Fig. 3 shows some important details of the experiment setup. Specifically, you need to carry out the following steps (see also Instruction Sheet of x-ray apparatus): – Mount the collimator in the collimator mount (a) (note the guide groove). – Attach the goniometer to the guide rods (d) in such a way that the distance s1 between the slit diaphragm of the collimator and the target arm is approx. 5 cm. Connect the ribbon cable (c) for controlling the goniometer. – Remove the cap of the end-window counter, insert the end-window counter in the sensor seat (e) and connect the counter tube lead to the socket marked GM-Tube. – Adjust the sensor seat (b) until the distance s2 between the target arm and the slit diaphragm of the sensor seat is approx. 6 cm. – Attach the target holder with target stage (f). – Loosen knurled screw (g), lay the NaCl crystal flat on the target stage, carefully raise the stage as far at it will go and then tighten the knurled screw with care (press against the screw lightly to prevent it from stripping). – Adjust the zero position of the goniometer measuring system as necessary (see Instruction Sheet of x-ray apparatus). Notes: NaCl crystals are hygroscopic and fragile. Store the crystals in a dry place. Avoid mechanical stresses on the crystal; handle the crystal by the short faces only. If the counting rate is too low, you can reduce the distance s2 between the target and the sensor somewhat. However, this distance must not be too small, as otherwise the angular resolution of the goniometer is no longer great enough to separate the characteristic Ka and Kb lines. Preparing a PC-based measurement: – Connect the RS−232 output to the serial interface on the PC (usually COM1 or COM2) using the 9-pin V.24 cable (included with the x-ray apparatus). – If you have not already done so, install the software “X-ray Apparatus” under Windows 9x/NT (see Instruction Sheet of x-ray apparatus) and select the desired language. Carrying out the experiment – Start the program “X-ray Apparatus”, check to make sure that the x-ray apparatus is properly connected and delete any existing measurement data by clicking the button or pressing F4. – Set the x-ray high voltage U = 35.0 kV, emission current I = 1.00 mA, measuring time per angular step Dt = 10 s and angular step width Db = 0.18. – Press the COUPLED key on the device to enable 2q coupling of the target and sensor; set the lower limit value of the target angle to 28 and the upper limit to 258. – Press the SCAN key to start the measurement and data transmission to the PC. – When the measurement is finished, save the measurement series to a file under a suitable name using the button or F2. Measuring example Fig. 4 shows the measured diffraction spectrum. Fig. 3 Experiment setup in Bragg configuration LEYBOLD Physics Leaflets P6.3.3.1 3