正在加载图片...

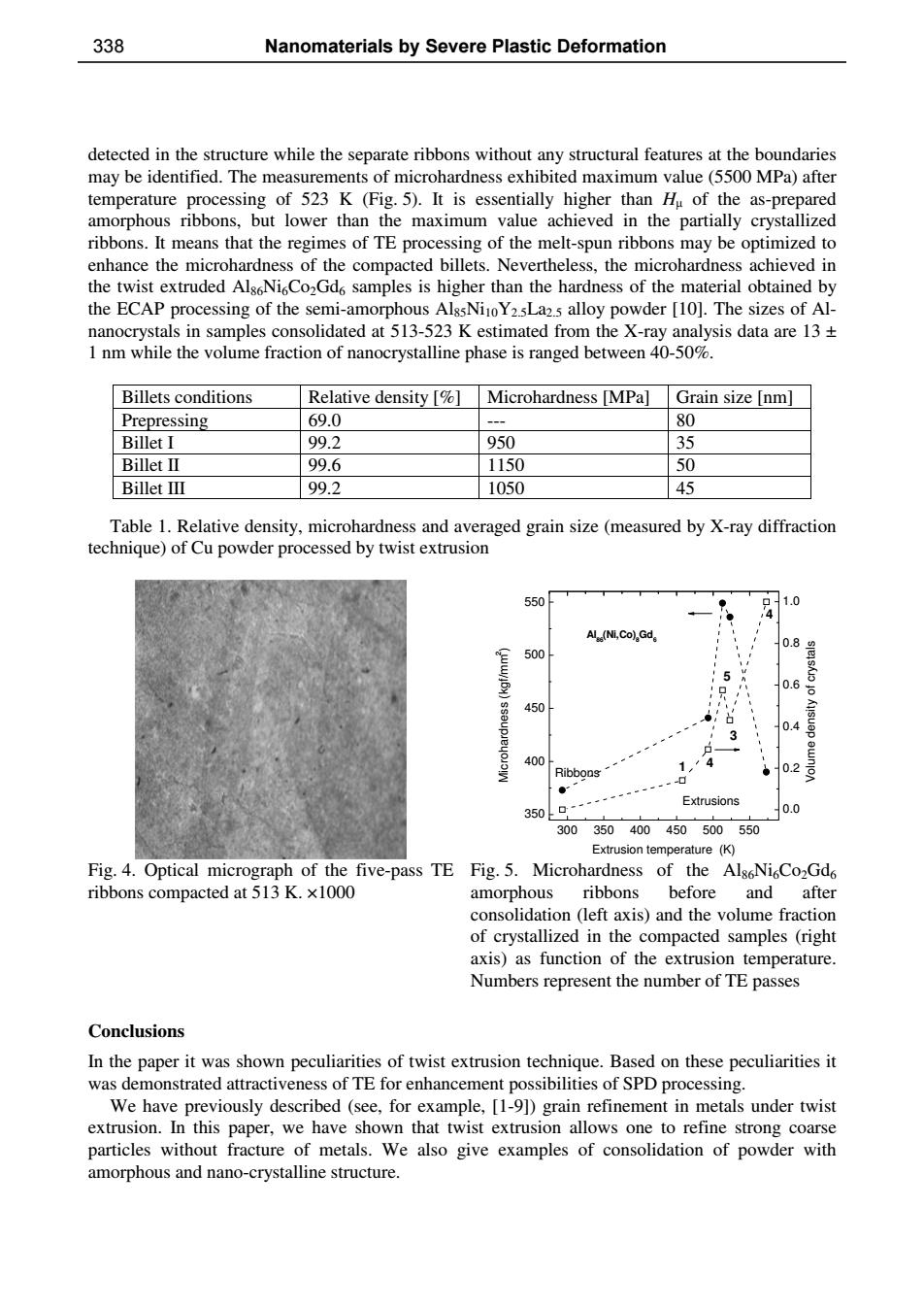

338 Nanomaterials by Severe Plastic Deformation detected in the structure while the separate ribbons without any structural features at the boundaries may be identified.The measurements of microhardness exhibited maximum value(5500 MPa)after temperature processing of 523 K (Fig.5).It is essentially higher than Hu of the as-prepared amorphous ribbons,but lower than the maximum value achieved in the partially crystallized ribbons.It means that the regimes of TE processing of the melt-spun ribbons may be optimized to enhance the microhardness of the compacted billets.Nevertheless,the microhardness achieved in the twist extruded AlsoNisCo2Gd6 samples is higher than the hardness of the material obtained by the ECAP processing of the semi-amorphous AlgsNioY2.sLa2.5 alloy powder [10].The sizes of Al- nanocrystals in samples consolidated at 513-523 K estimated from the X-ray analysis data are 13+ 1 nm while the volume fraction of nanocrystalline phase is ranged between 40-50%. Billets conditions Relative density [% Microhardness [MPa] Grain size nm Prepressing 69.0 80 Billet I 99.2 950 35 Billet II 99.6 1150 50 BilletⅢ 99.2 1050 45 Table 1.Relative density,microhardness and averaged grain size (measured by X-ray diffraction technique)of Cu powder processed by twist extrusion 550 81。 Al (Ni,Co)Gd E 500 08是 5 0.6 450 0.4 3 400 1,4 0.2 ●、 3500- Extrusions 0.0 300350400450500550 Extrusion temperature (K) Fig.4.Optical micrograph of the five-pass TE Fig.5.Microhardness of the Als6NiCo2Gd6 ribbons compacted at 513 K.x1000 amorphous ribbons before and after consolidation (left axis)and the volume fraction of crystallized in the compacted samples (right axis)as function of the extrusion temperature. Numbers represent the number of TE passes Conclusions In the paper it was shown peculiarities of twist extrusion technique.Based on these peculiarities it was demonstrated attractiveness of TE for enhancement possibilities of SPD processing. We have previously described (see,for example,[1-9])grain refinement in metals under twist extrusion.In this paper,we have shown that twist extrusion allows one to refine strong coarse particles without fracture of metals.We also give examples of consolidation of powder with amorphous and nano-crystalline structure.detected in the structure while the separate ribbons without any structural features at the boundaries may be identified. The measurements of microhardness exhibited maximum value (5500 MPa) after temperature processing of 523 K (Fig. 5). It is essentially higher than Hµ of the as-prepared amorphous ribbons, but lower than the maximum value achieved in the partially crystallized ribbons. It means that the regimes of TE processing of the melt-spun ribbons may be optimized to enhance the microhardness of the compacted billets. Nevertheless, the microhardness achieved in the twist extruded Al86Ni6Co2Gd6 samples is higher than the hardness of the material obtained by the ECAP processing of the semi-amorphous Al85Ni10Y2.5La2.5 alloy powder [10]. The sizes of Alnanocrystals in samples consolidated at 513-523 K estimated from the X-ray analysis data are 13 ± 1 nm while the volume fraction of nanocrystalline phase is ranged between 40-50%. Billets conditions Relative density [%] Microhardness [MPa] Grain size [nm] Prepressing 69.0 --- 80 Billet I 99.2 950 35 Billet II 99.6 1150 50 Billet III 99.2 1050 45 Table 1. Relative density, microhardness and averaged grain size (measured by X-ray diffraction technique) of Cu powder processed by twist extrusion 300 350 400 450 500 550 350 400 450 500 550 0.0 0.2 0.4 0.6 0.8 1.0 Microhardness (kgf/mm 2 ) Extrusion temperature (K) Al86(Ni,Co)8Gd6 Ribbons Extrusions 3 4 5 4 1 Volume density of crystals Fig. 4. Optical micrograph of the five-pass TE ribbons compacted at 513 K. ×1000 Fig. 5. Microhardness of the Al86Ni6Co2Gd6 amorphous ribbons before and after consolidation (left axis) and the volume fraction of crystallized in the compacted samples (right axis) as function of the extrusion temperature. Numbers represent the number of TE passes Conclusions In the paper it was shown peculiarities of twist extrusion technique. Based on these peculiarities it was demonstrated attractiveness of TE for enhancement possibilities of SPD processing. We have previously described (see, for example, [1-9]) grain refinement in metals under twist extrusion. In this paper, we have shown that twist extrusion allows one to refine strong coarse particles without fracture of metals. We also give examples of consolidation of powder with amorphous and nano-crystalline structure. 338 Nanomaterials by Severe Plastic Deformation