正在加载图片...

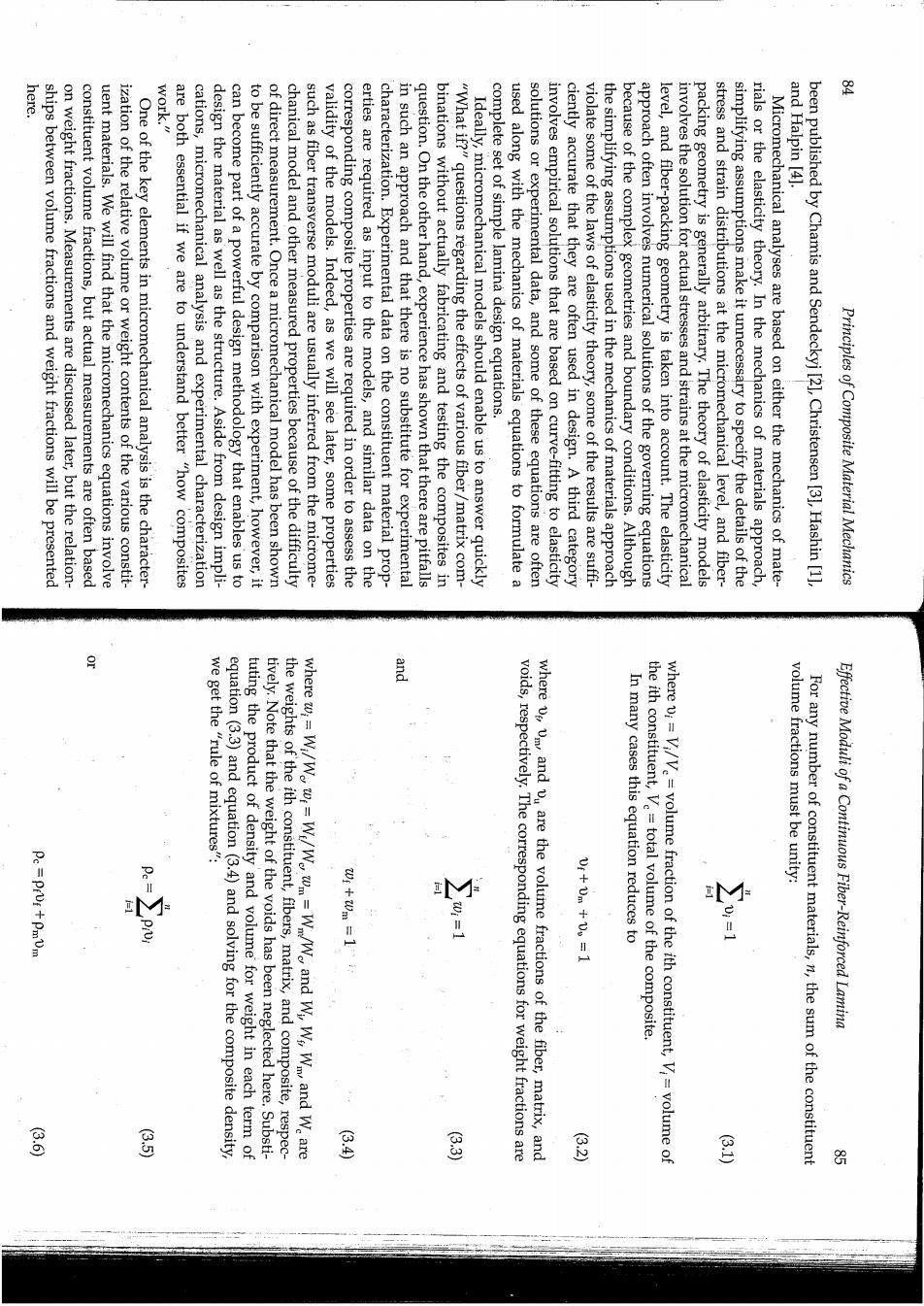

here. work." 图 and Halpin [4]. ships between volume fractions and weight fractions will be presented on weight fractions.Measurements are discussed later,but the relation- constituent volume fractions,but actual measurements are often based uent materials.We will find that the micromechanics equations involve ization of the relative volume or weight contents of the various constit- One of the key elements in micromechanical analysis is the character- are both essential if we are to understand better "how composites cations,micromechanical analysis and experimental characterization design the material as well as the structure.Aside from design impli- can become part of a powerful design methodology that enables us to to be sufficiently accurate by comparison with experiment,however,it of direct measurement.Once a micromechanical model has been shown chanical model and other measured properties because of the difficulty such as fiber transverse moduli are usually inferred from the microme- validity of the models.Indeed,as we will see later,some properties corresponding composite properties are required in order to assess the erties are required as input to the models,and similar data on the characterization.Experimental data on the constituent material prop- in such an approach and that there is no substitute for experimental question.On the other hand,experience has shown that there are pitfalls binations without actually fabricating and testing the composites in "What if?"questions regarding the effects of various fiber/matrix com- Ideally,micromechanical models should enable us to answer quickly complete set of simple lamina design equations. used along with the mechanics of materials equations to formulate a solutions or experimental data,and some of these equations are often involves empirical solutions that are based on curve-fitting to elasticity ciently accurate that they are often used in design.A third category violate some of the laws of elasticity theory,some of the results are suffi- the simplifying assumptions used in the mechanics of materials approach because of the complex geometries and boundary conditions.Although approach often involves numerical solutions of the governing equations level,and fiber-packing geometry is taken into account.The elasticity involves the solution for actual stresses and strains at the micromechanical packing geometry is generally arbitrary.The theory of elasticity models stress and strain distributions at the micromechanical level,and fiber- simplifying assumptions make it unnecessary to specify the details of the rials or the elasticity theory.In the mechanics of materials approach Micromechanical analyses are based on either the mechanics of mate- been published by Chamis and Sendeckyj [2],Christensen [3],Hashin [1] Principles of Composite Material Mechanics 登 we get the "rule of mixtures": Pe =PrUr+PmUm equation(3.3)and equation(3.4)and solving for the composite density, tuting the product of density and volume for weight in each term of tively.Note that the weight of the voids has been neglected here.Substi- the weights of the ith constituent,fibers,matrix,and composite,respec- where w:=Wi/Wo wr=Wi/Wo wm =Wm/Wo and Wi Ws,Wm,and W.are 8+8 voids,respectively.The corresponding equations for weight fractions are where vs vm,and vu are the volume fractions of the fiber,matrix,and Vr+Vm +Vo=1 In many cases this equation reduces to where v;=Vi/Ve=volume fraction of the ith constituent,Vi=volume of the ith constituent,V=total volume of the composite. volume fractions must be unity: For any number of constituent materials,n,the sum of the constituent Effective Moduli of a Continuous Fiber-Reinforced Lamina 8 罗 8 8 巴