正在加载图片...

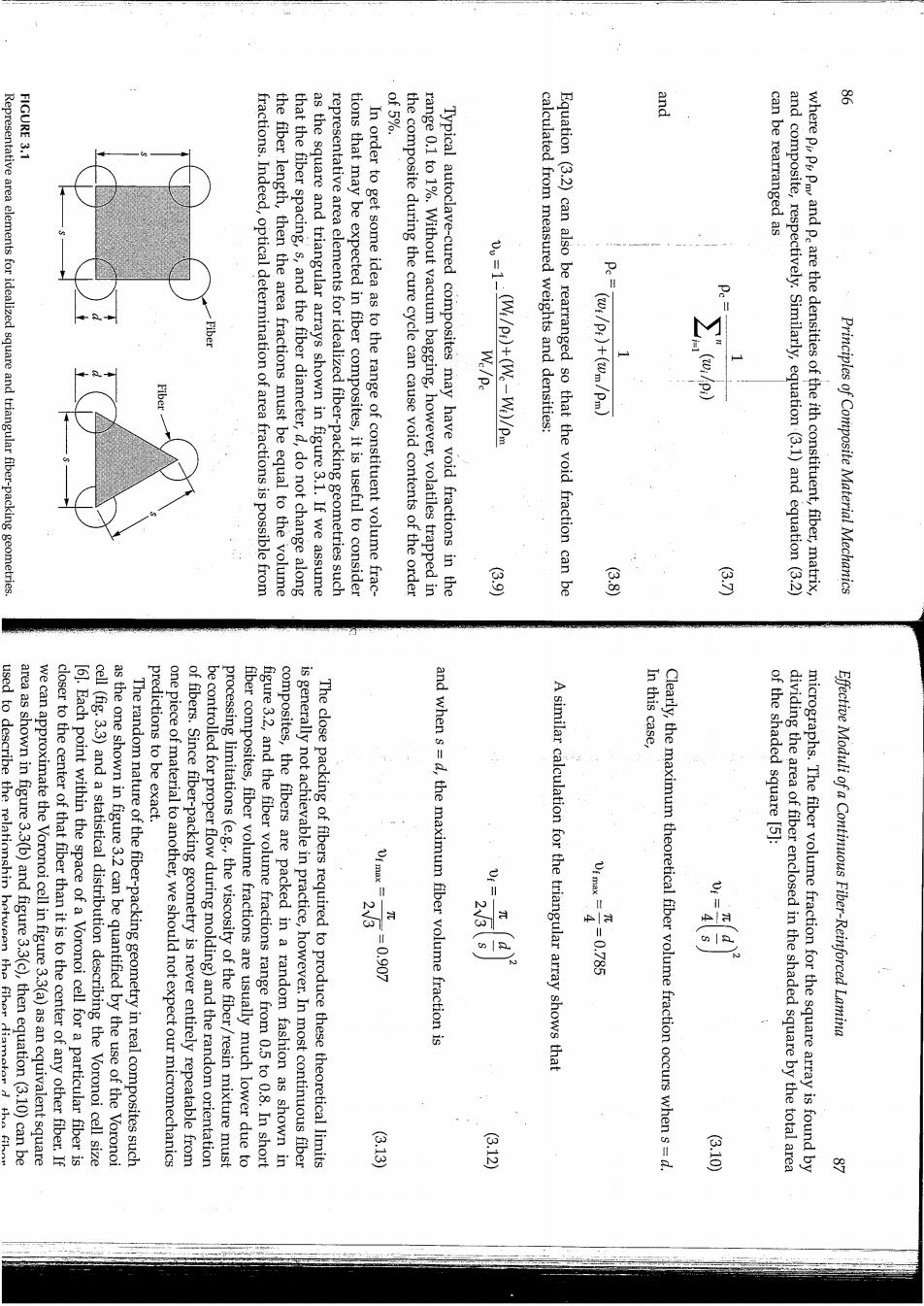

FIGURE 3.1 0F566. 置 Representative area elements for idealized square and triangular fibe fractions.Indeed,optical determination of area fractions is possible from the fiber length,then the area fractions must be equal to the volume as the square and triangular arrays shown in figure 3.1.If we assume representative area elements for idealized fiber-packing geometries such tions that may be expected in fiber composites,it is useful to consider the composite during the cure cycle can cause void contents of the order range 0.1 to 1%.Without vacuum bagging,however,volatiles trapped in can be rearranged as v.-1-(W/pi)+(W.-W)/pm calculated from measured weights and densities: and composite,respectively.Similarly,equation(3.1)and equation (3.2) where piPepm and pe are the densities of the ith constituent,fiber,matrix, er-packing geometries. that the fiber spacing,s,and the fiber diameter,d,do not change along In order to get some idea as to the range of constituent volume frac- Typical autoclave-cured composites may have void fractions in the Equation (3.2)can also be rearranged so that the void fraction can be Principles of Composite Material Mechanics 思 In this case, used to describe the relationshin hetween the fiher area as shown in figure 3.3(b)and figure 3.3(c),then equation(3.10)can be we can approximate the Voronoi cell in figure 3.3(a)as an equivalent square closer to the center of that fiber than it is to the center of any other fiber.If [6].Each point within the space of a Voronoi cell for a particular fiber is cell(fig.3.3)and a statistical distribution describing the Voronoi cell size as the one shown in figure 3.2 can be quantified by the use of the Voronoi The random nature of the fiber-packing geometry in real composites such predictions to be exact. one piece of material to another,we should not expect our micromechanics of fibers.Since fiber-packing geometry is never entirely repeatable from be controlled for proper flow during molding)and the random orientation processing limitations(e.g.,the viscosity of the fiber/resin mixture must fiber composites,fiber volume fractions are usually much lower due to figure 3.2,and the fiber volume fractions range from 0.5 to 0.8.In short composites,the fibers are packed in a random fashion as shown in is generally not achievable in practice,however.In most continuous fiber The close packing of fibers required to produce these theoretical limits -0.000 and when s=d,the maximum fiber volume fraction is A similar calculation for the triangular array shows that Clearly,the maximum theoretical fiber volume fraction occurs when s=d. of the shaded square [5]: dividing the area of fiber enclosed in the shaded square by the total area micrographs.The fiber volume fraction for the square array is found by Effective Moduli ofa Continuous Fiber-Reinforced Lamina e13 8.12 c.10