正在加载图片...

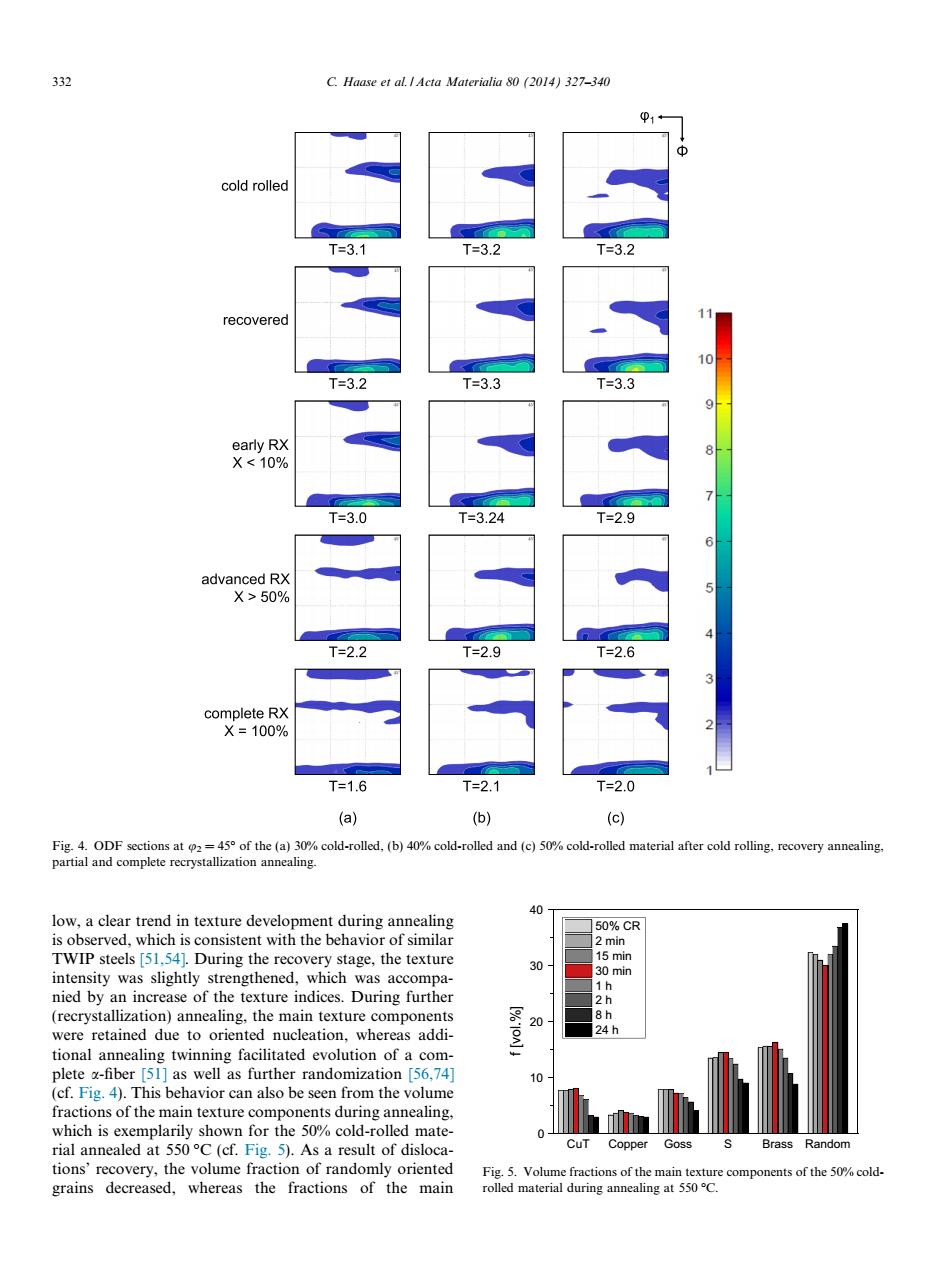

332 C.Haase et al.Acta Materialia 80 (2014)327-340 1+ cold rolled T=3.1 T=3.2 T=3.2 recovered 11 10 T=3.2 T=3.3 T=3.3 early RX X<10% T=3.0 T=3.24 T=2.9 advanced RX X>50% T=2.2 T=2.9 T=2.6 complete RX X=100% T=1.6 T=2.1 T=2.0 (a) (b) (c) Fig.4.ODF sections at 2=45 of the (a)30%cold-rolled,(b)40%cold-rolled and (c)50%cold-rolled material after cold rolling,recovery annealing. partial and complete recrystallization annealing. 40 low,a clear trend in texture development during annealing 50%CR is observed,which is consistent with the behavior of similar 2 min TWIP steels [51.54].During the recovery stage,the texture 15 min 30 intensity was slightly strengthened,which was accompa- 30 min 1h nied by an increase of the texture indices.During further 2h (recrystallization)annealing,the main texture components 20 8h were retained due to oriented nucleation,whereas addi- 24h tional annealing twinning facilitated evolution of a com- plete a-fiber [51]as well as further randomization [56.74] (cf.Fig.4).This behavior can also be seen from the volume fractions of the main texture components during annealing, which is exemplarily shown for the 50%cold-rolled mate- rial annealed at 550C(cf.Fig.5).As a result of disloca- CuT Copper Goss Brass Random tions'recovery,the volume fraction of randomly oriented Fig.5.Volume fractions of the main texture components of the 50%cold- grains decreased,whereas the fractions of the main rolled material during annealing at 550 C.low, a clear trend in texture development during annealing is observed, which is consistent with the behavior of similar TWIP steels [51,54]. During the recovery stage, the texture intensity was slightly strengthened, which was accompanied by an increase of the texture indices. During further (recrystallization) annealing, the main texture components were retained due to oriented nucleation, whereas additional annealing twinning facilitated evolution of a complete a-fiber [51] as well as further randomization [56,74] (cf. Fig. 4). This behavior can also be seen from the volume fractions of the main texture components during annealing, which is exemplarily shown for the 50% cold-rolled material annealed at 550 C (cf. Fig. 5). As a result of dislocations’ recovery, the volume fraction of randomly oriented grains decreased, whereas the fractions of the main Fig. 4. ODF sections at u2 = 45 of the (a) 30% cold-rolled, (b) 40% cold-rolled and (c) 50% cold-rolled material after cold rolling, recovery annealing, partial and complete recrystallization annealing. CuT Copper Goss S Brass Random 0 10 20 30 40 f [vol.%] 50% CR 2 min 15 min 30 min 1 h 2 h 8 h 24 h Fig. 5. Volume fractions of the main texture components of the 50% coldrolled material during annealing at 550 C. 332 C. Haase et al. / Acta Materialia 80 (2014) 327–340���