正在加载图片...

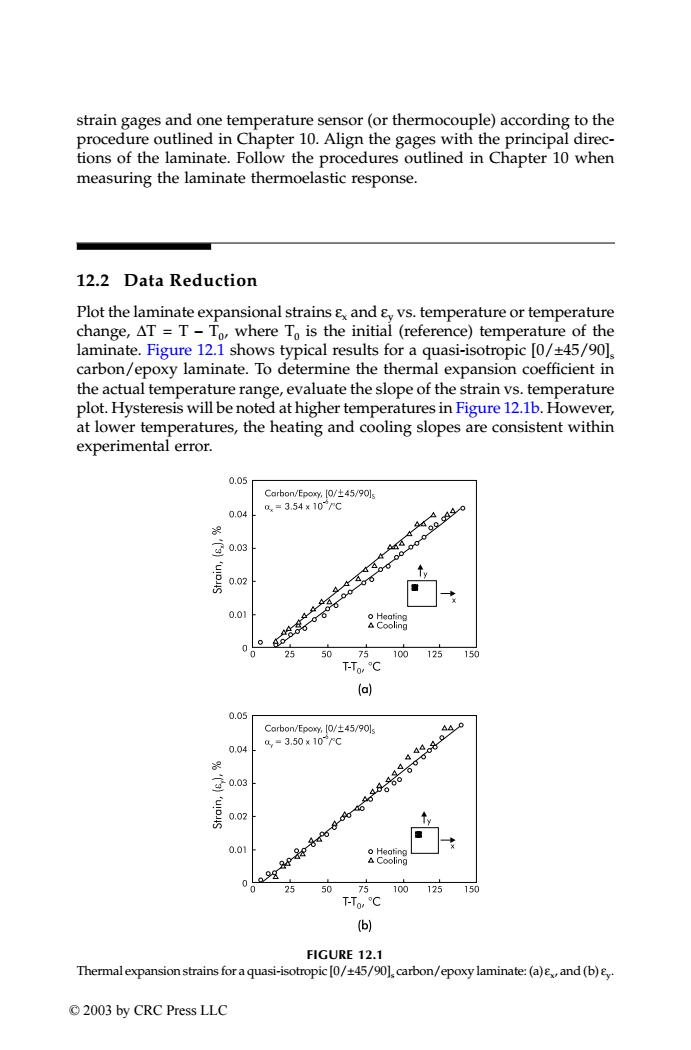

strain gages and one temperature sensor (or thermocouple)according to the procedure outlined in Chapter 10.Align the gages with the principal direc- tions of the laminate.Follow the procedures outlined in Chapter 10 when measuring the laminate thermoelastic response. 12.2 Data Reduction Plot the laminate expansional strains &x and E,vs.temperature or temperature change,AT=T-To,where To is the initial(reference)temperature of the laminate.Figure 12.1 shows typical results for a quasi-isotropic [0/+45/90 carbon/epoxy laminate.To determine the thermal expansion coefficient in the actual temperature range,evaluate the slope of the strain vs.temperature plot.Hysteresis will be noted at higher temperatures in Figure 12.1b.However, at lower temperatures,the heating and cooling slopes are consistent within experimental error. 0.05 Carbon/Epory,[0/45/901s 0.=3.54×10/℃ 0.04 alo 20.03 00 0.02 0.01 &889 0 50 75 100 125 150 T-To,C (a) 0.05 Carbon/Epoxy,[0/45/901s 0.04 a,=3.50x10rC 30.03 0.02 0.01 50 75 100 125 150 T-To,C ) FIGURE 12.1 Thermal expansion strains for a quasi-isotropic [0/45/901,carbon/epoxy laminate:(a),and(b). ©2003 by CRC Press LLCstrain gages and one temperature sensor (or thermocouple) according to the procedure outlined in Chapter 10. Align the gages with the principal directions of the laminate. Follow the procedures outlined in Chapter 10 when measuring the laminate thermoelastic response. 12.2 Data Reduction Plot the laminate expansional strains εx and εy vs. temperature or temperature change, ∆T = T – T0, where T0 is the initial (reference) temperature of the laminate. Figure 12.1 shows typical results for a quasi-isotropic [0/±45/90]s carbon/epoxy laminate. To determine the thermal expansion coefficient in the actual temperature range, evaluate the slope of the strain vs. temperature plot. Hysteresis will be noted at higher temperatures in Figure 12.1b. However, at lower temperatures, the heating and cooling slopes are consistent within experimental error. FIGURE 12.1 Thermal expansion strains for a quasi-isotropic [0/±45/90]s carbon/epoxy laminate: (a) εx, and (b) εy. TX001_ch12_Frame Page 165 Saturday, September 21, 2002 5:05 AM © 2003 by CRC Press LLC