正在加载图片...

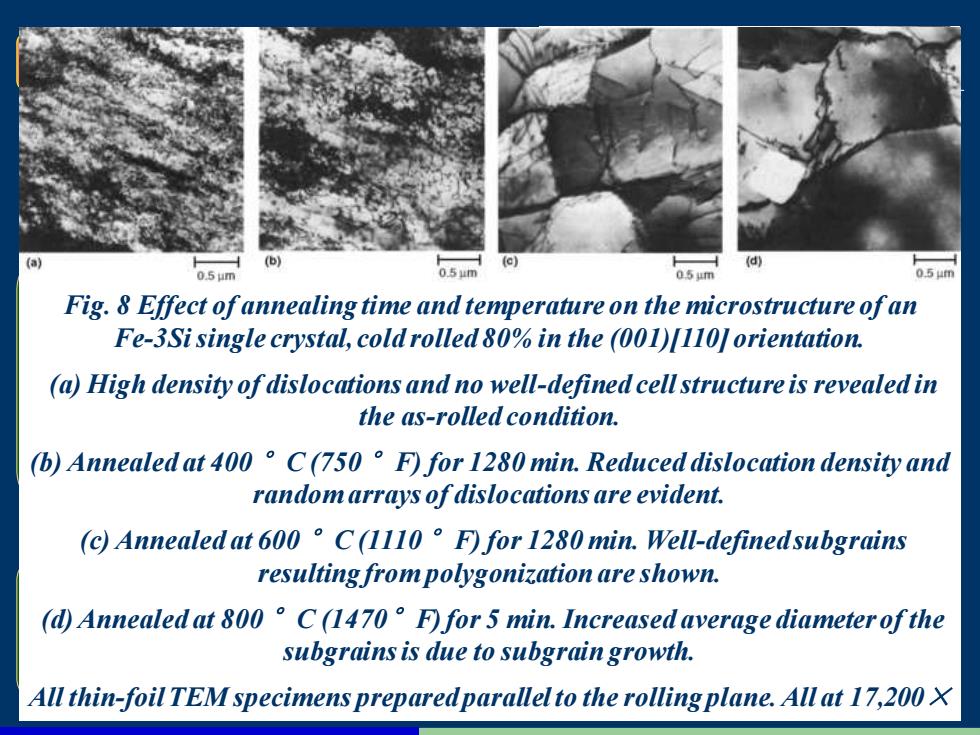

(b) o.5 um 051 0.5 um Fig.8 Effect ofannealing time and temperature on the microstructure ofan Fe-3Si single crystal,cold rolled 80%in the (001)(110|orientation. (a)High density of dislocations and no well-defined cell structure is revealed in the as-rolled condition. (b)Annealed at 400 C(750 F)for 1280 min.Reduced dislocation density and random arrays of dislocations are evident. (c)Annealed at 600C(1110 F)for 1280 min.Well-definedsubgrains resulting from polygonization are shown. (d)Annealed at 800 C(1470 F)for 5 min.Increased average diameterofthe subgrains is due to subgrain growth. All thin-foil TEM specimens preparedparallel to the rolling plane.All at 17,200 X 2.3 金属的塑性加工 2.3.2 金属的再结晶(recrystallization) 1、回复(recovery) (1) 回复(recovery):变形后的 金属在加热温度不高时,变形 金属的组织、力学性能变化不 大;物理、化学性能部分地恢 复到变形前的状态;残余内应 力显著下降,这一阶段称为~ 。 (2)回复退火:消除残余内应力, 防止变形与开裂。或称低温退 火,去应力退火(stress relief anneal) T回复 =(0.25 ~ 0.3)T熔点 Fig. 8 Effect of annealing time and temperature on the microstructure of an Fe-3Si single crystal, cold rolled 80% in the (001)[110] orientation. (a) High density of dislocations and no well-defined cell structure is revealed in the as-rolled condition. (b) Annealed at 400 °C (750 °F) for 1280 min. Reduced dislocation density and random arrays of dislocations are evident. (c) Annealed at 600 °C (1110 °F) for 1280 min. Well-defined subgrains resulting from polygonization are shown. (d) Annealed at 800 °C (1470°F) for 5 min. Increased average diameter of the subgrainsis due to subgrain growth. All thin-foil TEM specimens prepared parallel to the rolling plane. All at 17,200×