正在加载图片...

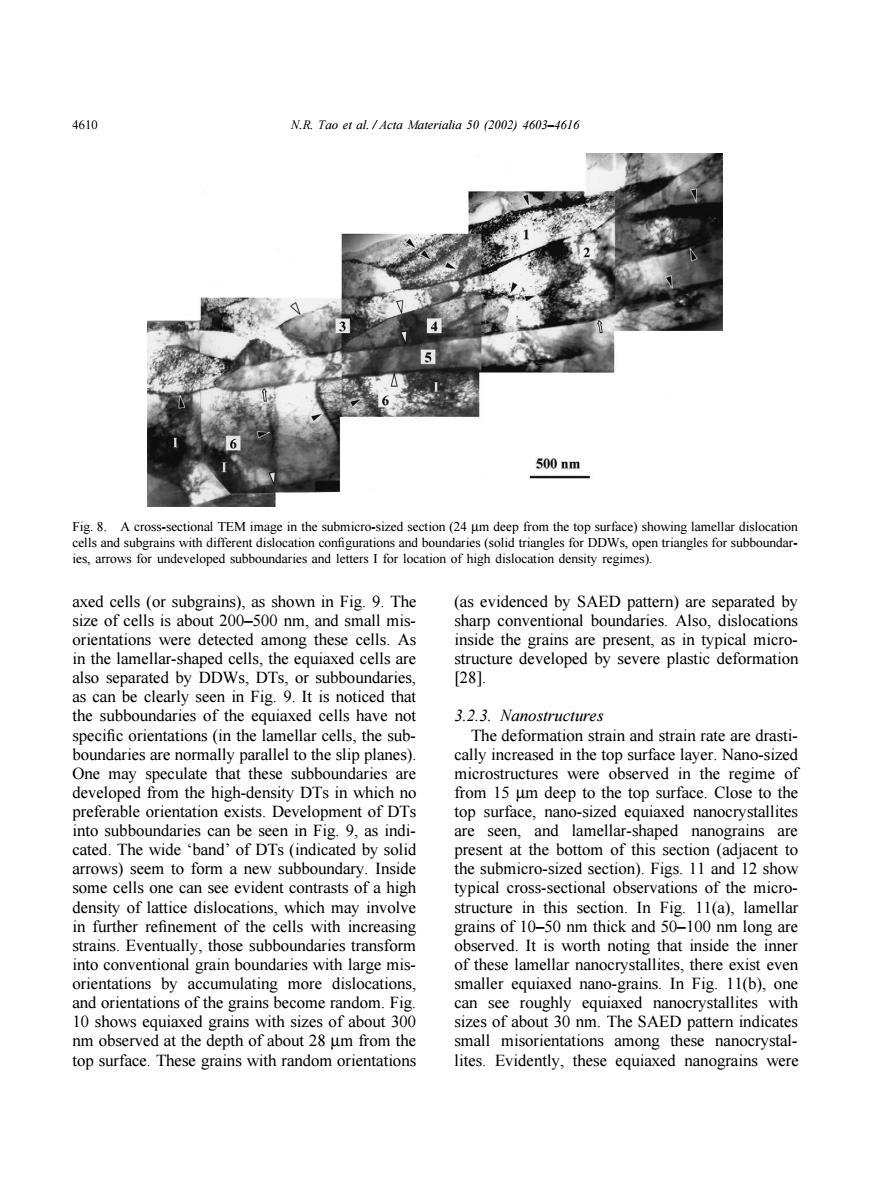

4610 N.R.Tao et al.Acta Materialia 50 (2002)4603-4616 500nm Fig.8.A cross-sectional TEM image in the submicro-sized section(24 um deep from the top surface)showing lamellar dislocation cells and subgrains with different dislocation configurations and boundaries (solid triangles for DDWs,open triangles for subboundar- ies,arrows for undeveloped subboundaries and letters I for location of high dislocation density regimes). axed cells (or subgrains).as shown in Fig.9.The (as evidenced by SAED pattern)are separated by size of cells is about 200-500 nm.and small mis- sharp conventional boundaries.Also,dislocations orientations were detected among these cells.As inside the grains are present,as in typical micro- in the lamellar-shaped cells,the equiaxed cells are structure developed by severe plastic deformation also separated by DDWs,DTs,or subboundaries, [281 as can be clearly seen in Fig.9.It is noticed that the subboundaries of the equiaxed cells have not 3.2.3.Nanostructures specific orientations (in the lamellar cells,the sub- The deformation strain and strain rate are drasti- boundaries are normally parallel to the slip planes). cally increased in the top surface layer.Nano-sized One may speculate that these subboundaries are microstructures were observed in the regime of developed from the high-density DTs in which no from 15 um deep to the top surface.Close to the preferable orientation exists.Development of DTs top surface,nano-sized equiaxed nanocrystallites into subboundaries can be seen in Fig.9,as indi- are seen,and lamellar-shaped nanograins are cated.The wide 'band'of DTs (indicated by solid present at the bottom of this section (adjacent to arrows)seem to form a new subboundary.Inside the submicro-sized section).Figs.11 and 12 show some cells one can see evident contrasts of a high typical cross-sectional observations of the micro- density of lattice dislocations,which may involve structure in this section.In Fig.11(a),lamellar in further refinement of the cells with increasing grains of 10-50 nm thick and 50-100 nm long are strains.Eventually,those subboundaries transform observed.It is worth noting that inside the inner into conventional grain boundaries with large mis- of these lamellar nanocrystallites,there exist even orientations by accumulating more dislocations, smaller equiaxed nano-grains.In Fig.11(b),one and orientations of the grains become random.Fig. can see roughly equiaxed nanocrystallites with 10 shows equiaxed grains with sizes of about 300 sizes of about 30 nm.The SAED pattern indicates nm observed at the depth of about 28 um from the small misorientations among these nanocrystal- top surface.These grains with random orientations lites.Evidently,these equiaxed nanograins were4610 N.R. Tao et al. / Acta Materialia 50 (2002) 4603–4616 Fig. 8. A cross-sectional TEM image in the submicro-sized section (24 µm deep from the top surface) showing lamellar dislocation cells and subgrains with different dislocation configurations and boundaries (solid triangles for DDWs, open triangles for subboundaries, arrows for undeveloped subboundaries and letters I for location of high dislocation density regimes). axed cells (or subgrains), as shown in Fig. 9. The size of cells is about 200–500 nm, and small misorientations were detected among these cells. As in the lamellar-shaped cells, the equiaxed cells are also separated by DDWs, DTs, or subboundaries, as can be clearly seen in Fig. 9. It is noticed that the subboundaries of the equiaxed cells have not specific orientations (in the lamellar cells, the subboundaries are normally parallel to the slip planes). One may speculate that these subboundaries are developed from the high-density DTs in which no preferable orientation exists. Development of DTs into subboundaries can be seen in Fig. 9, as indicated. The wide ‘band’ of DTs (indicated by solid arrows) seem to form a new subboundary. Inside some cells one can see evident contrasts of a high density of lattice dislocations, which may involve in further refinement of the cells with increasing strains. Eventually, those subboundaries transform into conventional grain boundaries with large misorientations by accumulating more dislocations, and orientations of the grains become random. Fig. 10 shows equiaxed grains with sizes of about 300 nm observed at the depth of about 28 µm from the top surface. These grains with random orientations (as evidenced by SAED pattern) are separated by sharp conventional boundaries. Also, dislocations inside the grains are present, as in typical microstructure developed by severe plastic deformation [28]. 3.2.3. Nanostructures The deformation strain and strain rate are drastically increased in the top surface layer. Nano-sized microstructures were observed in the regime of from 15 µm deep to the top surface. Close to the top surface, nano-sized equiaxed nanocrystallites are seen, and lamellar-shaped nanograins are present at the bottom of this section (adjacent to the submicro-sized section). Figs. 11 and 12 show typical cross-sectional observations of the microstructure in this section. In Fig. 11(a), lamellar grains of 10–50 nm thick and 50–100 nm long are observed. It is worth noting that inside the inner of these lamellar nanocrystallites, there exist even smaller equiaxed nano-grains. In Fig. 11(b), one can see roughly equiaxed nanocrystallites with sizes of about 30 nm. The SAED pattern indicates small misorientations among these nanocrystallites. Evidently, these equiaxed nanograins were