正在加载图片...

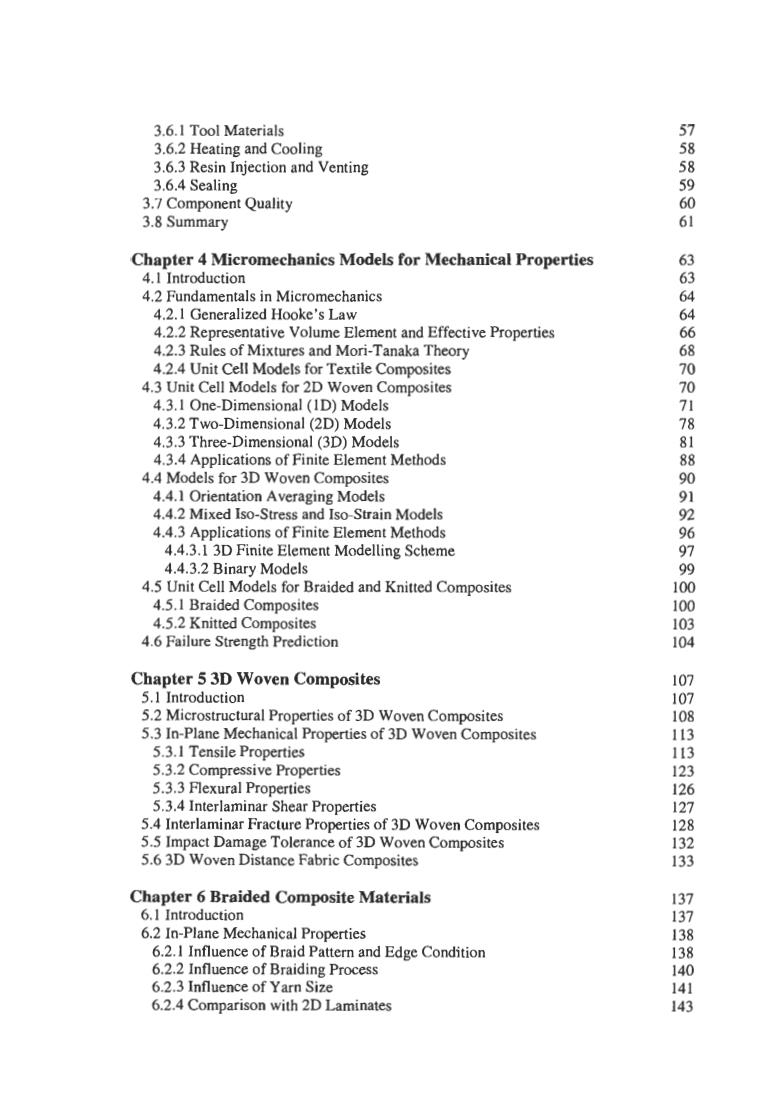

3.6.1 Tool Materials 3.6.2 Heating and Cooling 3.6.3 Resin Injection and Venting 3.6.4 Sealing 3.7 Component Quality 7383869606 3.8 Summary Chapter 4 Micromechanics Models for Mechanical Properties 63 4.1 Introduction 4.2 Fundamentals in Micromechanics 4.2.1 Generalized Hooke's Law 4.2.2 Representative Volume Element and Effective Properties 4.2.3 Rules of Mixtures and Mori-Tanaka Theory 4.2.4 Unit Cell Models for Textile Composites 4.3 Unit Cell Models for 2D Woven Composites 4.3.1 One-Dimensional (ID)Models 4.3.2 Two-Dimensional(2D)Models 4.3.3 Three-Dimensional (3D)Models 4.3.4 Applications of Finite Element Methods 4.4 Models for 3D Woven Composites 4.4.1 Orientation Averaging Models 4.4.2 Mixed Iso-Stress and Iso-Strain Models 4.4.3 Applications of Finite Element Methods 4.4.3.1 3D Finite Element Modelling Scheme 4.4.3.2 Binary Models 6446600738809269901004 4.5 Unit Cell Models for Braided and Knitted Composites 4.5.1 Braided Composites 4.5.2 Knitted Composites 4.6 Failure Strength Prediction Chapter 5 3D Woven Composites 5.】Introduction 5.2 Microstructural Properties of 3D Woven Composites 5.3 In-Plane Mechanical Properties of 3D Woven Composites 00W3 5.3.1 Tensile Properties 5.3.2 Compressive Properties 5.3.3 Flexural Properties 126 5.3.4 Interlaminar Shear Properties 5.4 Interlaminar Fracture Properties of 3D Woven Composites 128 5.5 Impact Damage Tolerance of 3D Woven Composites 132 5.6 3D Woven Distance Fabric Composites 133 Chapter 6 Braided Composite Materials 137 6.1 Introduction 137 6.2 In-Plane Mechanical Properties 138 6.2.1 Influence of Braid Pattern and Edge Condition 138 6.2.2 Influence of Braiding Process 6.2.3 Influence of Yarn Size 9 6.2.4 Comparison with 2D Laminates 1433.6.1 Tool Materials 3.6.2 Heating and Cooling 3.6.3 Resin Injection and Venting 3.6.4 Sealing 3.7 Component Quality 3.8 Summary Chapter 4 Micromechanics Models for Mechanical Properties 4.1 Introduction 4.2 Fundamentals in Micromechanics 4.2.1 Generalized Hooke’s Law 4.2.2 Representative Volume Element and Effective Properties 4.2.3 Rules of Mixtures and Mori-Tanaka Theory 4.2.4 Unit Cell Models for Textile Composites 4.3 Unit Cell Models for 2D Woven Composites 4.3.1 One-Dimensional (1D) Models 4.3.2 Two-Dimensional (2D) Models 4.3.3 Three-Dimensional (3D) Models 4.3.4 Applications of Finite Element Methods 4.4 Models for 3D Woven Composites 4.4.1 Orientation Averaging Models 4.4.2 Mixed Iso-Stress and Iso-Strain Models 4.4.3 Applications of Finite Element Methods 4.4.3.1 3D Finite Element Modelling Scheme 4.4.3.2 Binary Models 4.5.1 Braided Composites 4.5.2 Knitted Composites 4.6 Failure Strength Prediction 4.5 Unit Cell Models for Braided and Knitted Composites Chapter 5 3D Woven Composites 5.1 Introduction 5.2 Microstructural Properties of 3D Woven Composites 5.3 In-Plane Mechanical Properties of 3D Woven Composites 5.3.1 Tensile Properties 5.3.2 Compressive Properties 5.3.3 Flexural Properties 5.3.4 Interlaminar Shear Properties 5.4 Interlaminar Fracture Properties of 3D Woven Composites 5.5 Impact Damage Tolerance of 3D Woven Composites 5.6 3D Woven Distance Fabric Composites Chapter 6 Braided Composite Materials 6.1 Introduction 6.2 In-Plane Mechanical Properties 6.2.1 Influence of Braid Pattern and Edge Condition 6.2.2 Influence of Braiding Process 6.2.3 Influence of Yarn Size 6.2.4 Comparison with 2D Laminates 57 58 58 59 60 61 63 63 64 64 66 68 70 70 71 78 81 88 90 91 92 96 97 99 100 100 103 104 1 07 1 07 108 113 113 123 126 127 128 132 133 137 137 138 138 140 141 143