正在加载图片...

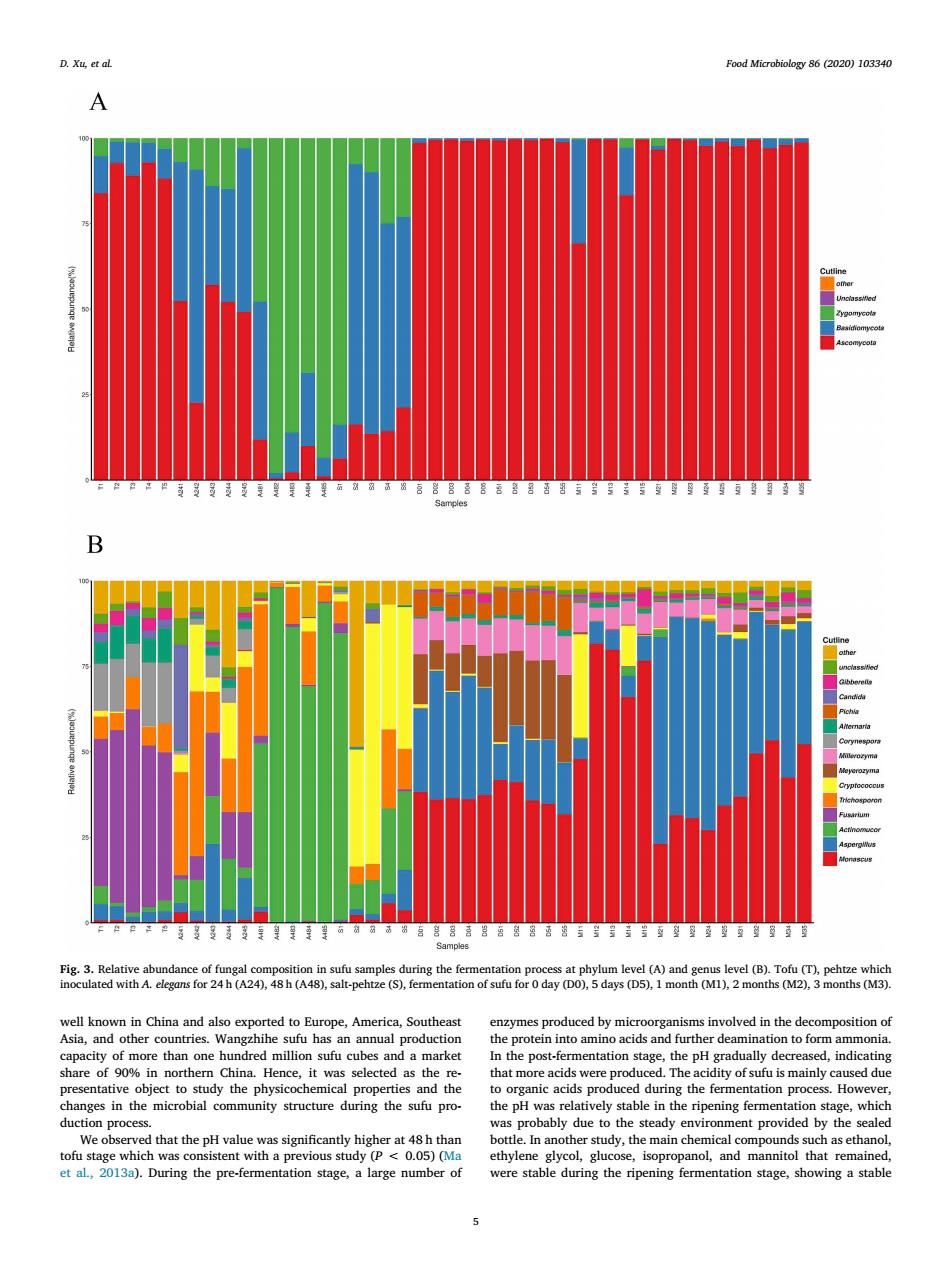

A B capacity of ore than o hundred million market the the,indicating organic ac uced during the fem duction proces was probably due to the ste oment provided by the sea tofu stage which cthe血a nol and mannitol that remained et al,2013a).During the pre-fermentation stage,a large number of well known in China and also exported to Europe, America, Southeast Asia, and other countries. Wangzhihe sufu has an annual production capacity of more than one hundred million sufu cubes and a market share of 90% in northern China. Hence, it was selected as the representative object to study the physicochemical properties and the changes in the microbial community structure during the sufu production process. We observed that the pH value was significantly higher at 48 h than tofu stage which was consistent with a previous study (P < 0.05) (Ma et al., 2013a). During the pre-fermentation stage, a large number of enzymes produced by microorganisms involved in the decomposition of the protein into amino acids and further deamination to form ammonia. In the post-fermentation stage, the pH gradually decreased, indicating that more acids were produced. The acidity of sufu is mainly caused due to organic acids produced during the fermentation process. However, the pH was relatively stable in the ripening fermentation stage, which was probably due to the steady environment provided by the sealed bottle. In another study, the main chemical compounds such as ethanol, ethylene glycol, glucose, isopropanol, and mannitol that remained, were stable during the ripening fermentation stage, showing a stable Fig. 3. Relative abundance of fungal composition in sufu samples during the fermentation process at phylum level (A) and genus level (B). Tofu (T), pehtze which inoculated with A. elegans for 24 h (A24), 48 h (A48), salt-pehtze (S), fermentation of sufu for 0 day (D0), 5 days (D5), 1 month (M1), 2 months (M2), 3 months (M3). D. Xu, et al. Food Microbiology 86 (2020) 103340 5