正在加载图片...

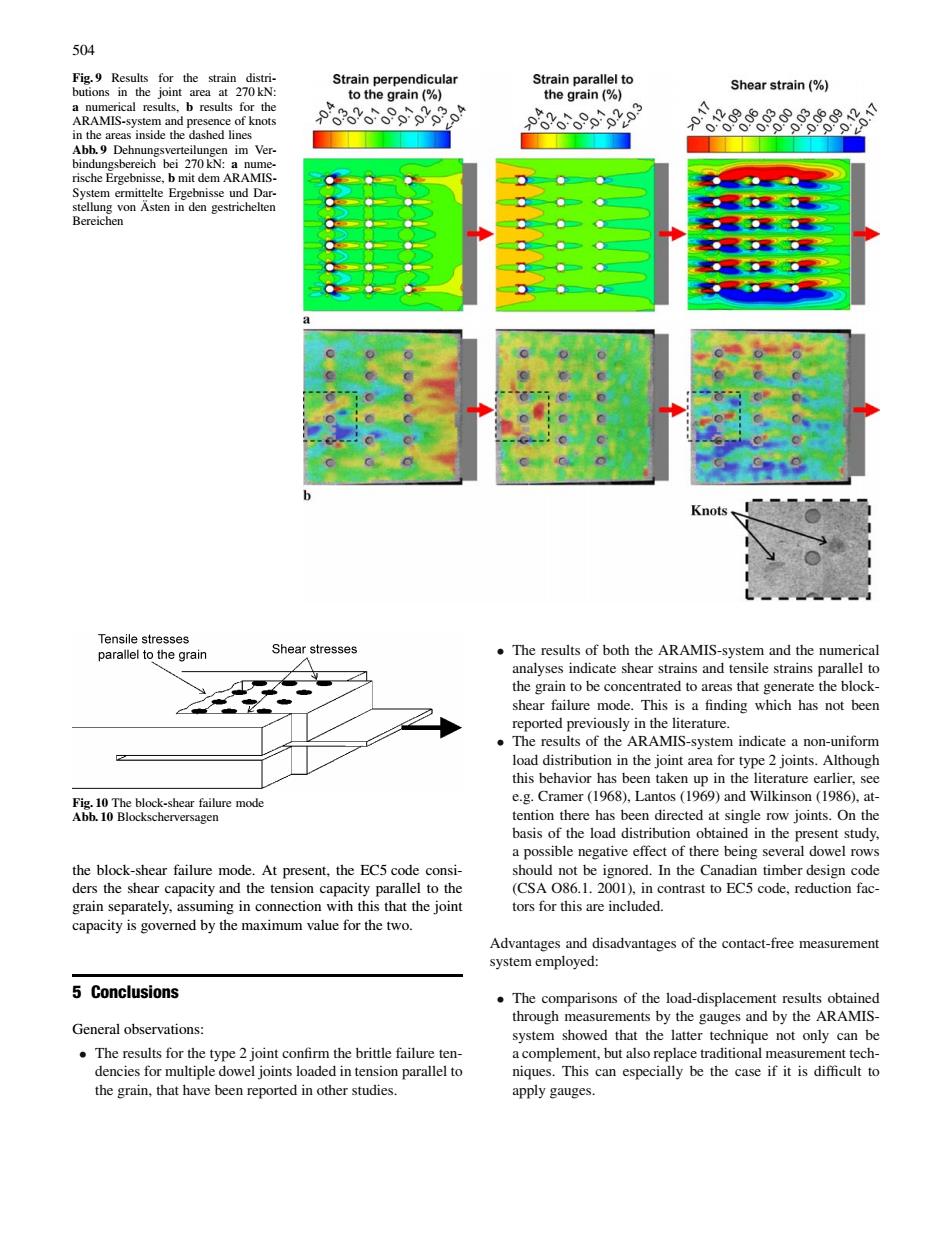

504 stongPnr stneg3n Shear strain(%) results fo im Ver 。 Knots Shear stresses .The results of both the ARAMIS-system and the numerical shear failure mode.This is a finding which has not bee reported previously in the literature. he results of the MIS-system indicate a no e.g.Cramer (1968).Lantos (1969)and Wilkinsc n(1986.2 w joints stud a possble negative effect of there being severa owe grain separately.assumine in connection with this that the joint tors for this are included. capacity is governed by the maximum value for the two disadvantages of the contact-free measurement 5 Conclusions The cm of thed-dispacemn General observations: system showed that the latter technique not only can be pply gauges504 Fig. 9 Results for the strain distributions in the joint area at 270 kN: a numerical results, b results for the ARAMIS-system and presence of knots in the areas inside the dashed lines Abb. 9 Dehnungsverteilungen im Verbindungsbereich bei 270 kN: a numerische Ergebnisse, b mit dem ARAMISSystem ermittelte Ergebnisse und Darstellung von Ästen in den gestrichelten Bereichen Fig. 10 The block-shear failure mode Abb. 10 Blockscherversagen the block-shear failure mode. At present, the EC5 code considers the shear capacity and the tension capacity parallel to the grain separately, assuming in connection with this that the joint capacity is governed by the maximum value for the two. 5 Conclusions General observations: • The results for the type 2 joint confirm the brittle failure tendencies for multiple dowel joints loaded in tension parallel to the grain, that have been reported in other studies. • The results of both the ARAMIS-system and the numerical analyses indicate shear strains and tensile strains parallel to the grain to be concentrated to areas that generate the blockshear failure mode. This is a finding which has not been reported previously in the literature. • The results of the ARAMIS-system indicate a non-uniform load distribution in the joint area for type 2 joints. Although this behavior has been taken up in the literature earlier, see e.g. Cramer (1968), Lantos (1969) and Wilkinson (1986), attention there has been directed at single row joints. On the basis of the load distribution obtained in the present study, a possible negative effect of there being several dowel rows should not be ignored. In the Canadian timber design code (CSA O86.1. 2001), in contrast to EC5 code, reduction factors for this are included. Advantages and disadvantages of the contact-free measurement system employed: • The comparisons of the load-displacement results obtained through measurements by the gauges and by the ARAMISsystem showed that the latter technique not only can be a complement, but also replace traditional measurement techniques. This can especially be the case if it is difficult to apply gauges