正在加载图片...

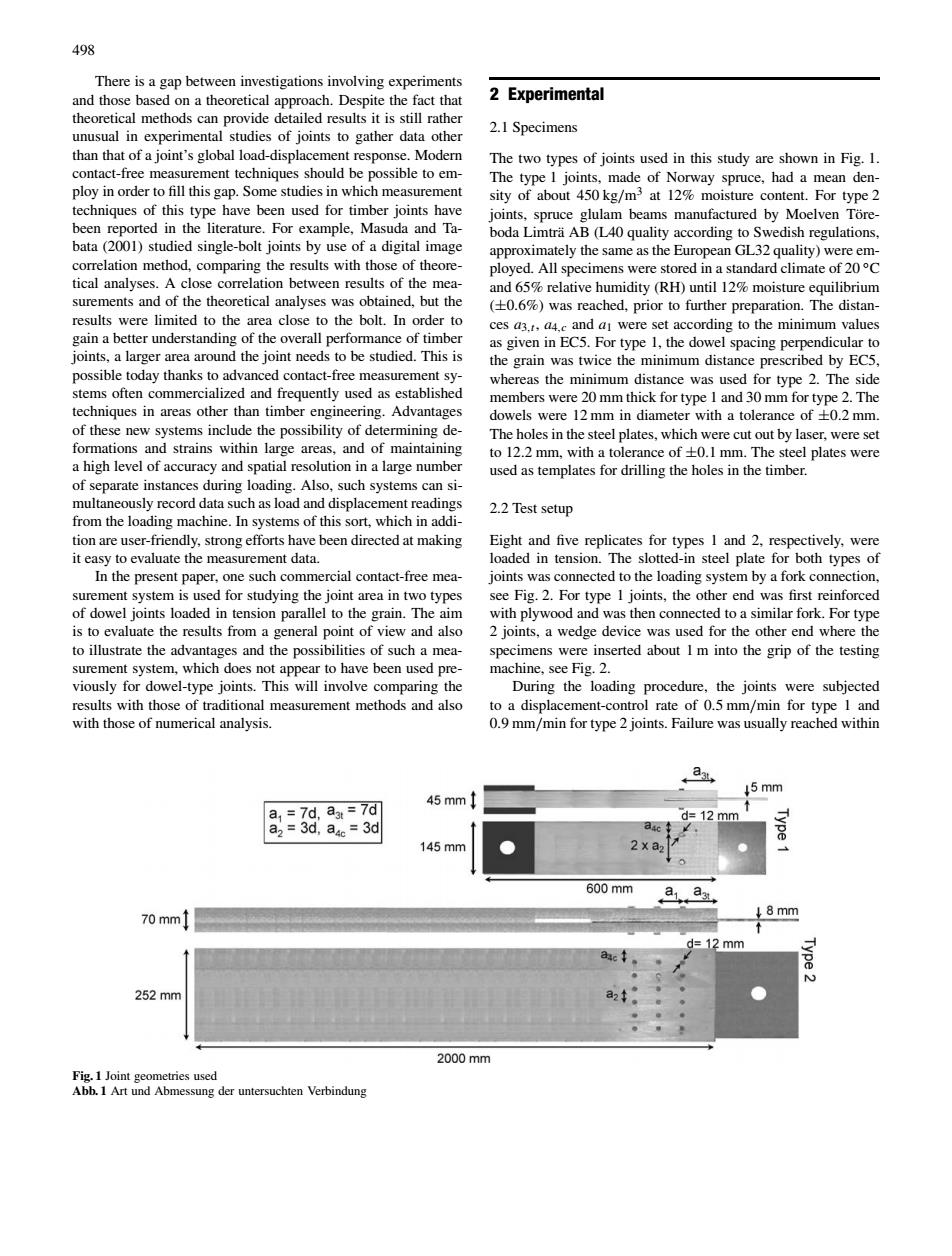

498 2 Experimental 2.1 Specimens studies of joints to gather data other fjont' The two types of joints used in this study are shown in Fig.1. ploy in order to fill this gap.Some studies in which measur this type have been oints glulam beams manufactured by Moelven Tore boda Limr AB (L40 quality according to Swedish regulations method,comparing the results with those OClAecsaneash A ts of nd65%TeihaehmidyRH)ntl12%moistueegiim results were limited to the area close to the bolt.In order to (.6%)was reached,prior to further preparatior dicular to ntact-fre s the minimum for type fo 27 of dete dowels were 12mm in diameter with a tolerance of 0.2 mm ations and strains within largc arcas.and of maintaining 3 a high level of accuracy and spatial resolution in a large number from the loading machine.In systems of this sort,which in 2.2Test setup onare,strong ve been directed at making In the present paner one such mmercial contact-free mea oints onected to the loading system by a fork co ection. surement system is used for studying the joint area in two types Fig.2.For type I joints,the other end was first reinforced P sed forh o illustrate the advantage and the po ssibilities of such a mea mens were inserted about Im into the grip of the testing ystm.which ma hinc..the joints esults with those of ment methods and also to a displ ent-control rate of 0.5 mm/min for e 1 an with those of numerical analysis. 09mm/n for ypen Falrlah 15 mm 8网 45mm1■ mm ● 2 600 mm 1 x 70mm1 ↓8mm 12mm ahc1。 252m 2000mm498 There is a gap between investigations involving experiments and those based on a theoretical approach. Despite the fact that theoretical methods can provide detailed results it is still rather unusual in experimental studies of joints to gather data other than that of a joint’s global load-displacement response. Modern contact-free measurement techniques should be possible to employ in order to fill this gap. Some studies in which measurement techniques of this type have been used for timber joints have been reported in the literature. For example, Masuda and Tabata (2001) studied single-bolt joints by use of a digital image correlation method, comparing the results with those of theoretical analyses. A close correlation between results of the measurements and of the theoretical analyses was obtained, but the results were limited to the area close to the bolt. In order to gain a better understanding of the overall performance of timber joints, a larger area around the joint needs to be studied. This is possible today thanks to advanced contact-free measurement systems often commercialized and frequently used as established techniques in areas other than timber engineering. Advantages of these new systems include the possibility of determining deformations and strains within large areas, and of maintaining a high level of accuracy and spatial resolution in a large number of separate instances during loading. Also, such systems can simultaneously record data such as load and displacement readings from the loading machine. In systems of this sort, which in addition are user-friendly, strong efforts have been directed at making it easy to evaluate the measurement data. In the present paper, one such commercial contact-free measurement system is used for studying the joint area in two types of dowel joints loaded in tension parallel to the grain. The aim is to evaluate the results from a general point of view and also to illustrate the advantages and the possibilities of such a measurement system, which does not appear to have been used previously for dowel-type joints. This will involve comparing the results with those of traditional measurement methods and also with those of numerical analysis. Fig. 1 Joint geometries used Abb. 1 Art und Abmessung der untersuchten Verbindung 2 Experimental 2.1 Specimens The two types of joints used in this study are shown in Fig. 1. The type 1 joints, made of Norway spruce, had a mean density of about 450 kg/m3 at 12% moisture content. For type 2 joints, spruce glulam beams manufactured by Moelven Töreboda Limträ AB (L40 quality according to Swedish regulations, approximately the same as the European GL32 quality) were employed. All specimens were stored in a standard climate of 20 ◦C and 65% relative humidity (RH) until 12% moisture equilibrium (±0.6%) was reached, prior to further preparation. The distances a3,t, a4,c and a1 were set according to the minimum values as given in EC5. For type 1, the dowel spacing perpendicular to the grain was twice the minimum distance prescribed by EC5, whereas the minimum distance was used for type 2. The side members were 20 mm thick for type 1 and 30 mm for type 2. The dowels were 12 mm in diameter with a tolerance of ±0.2 mm. The holes in the steel plates, which were cut out by laser, were set to 12.2 mm, with a tolerance of ±0.1 mm. The steel plates were used as templates for drilling the holes in the timber. 2.2 Test setup Eight and five replicates for types 1 and 2, respectively, were loaded in tension. The slotted-in steel plate for both types of joints was connected to the loading system by a fork connection, see Fig. 2. For type 1 joints, the other end was first reinforced with plywood and was then connected to a similar fork. For type 2 joints, a wedge device was used for the other end where the specimens were inserted about 1 m into the grip of the testing machine, see Fig. 2. During the loading procedure, the joints were subjected to a displacement-control rate of 0.5 mm/min for type 1 and 0.9 mm/min for type 2 joints. Failure was usually reached within