正在加载图片...

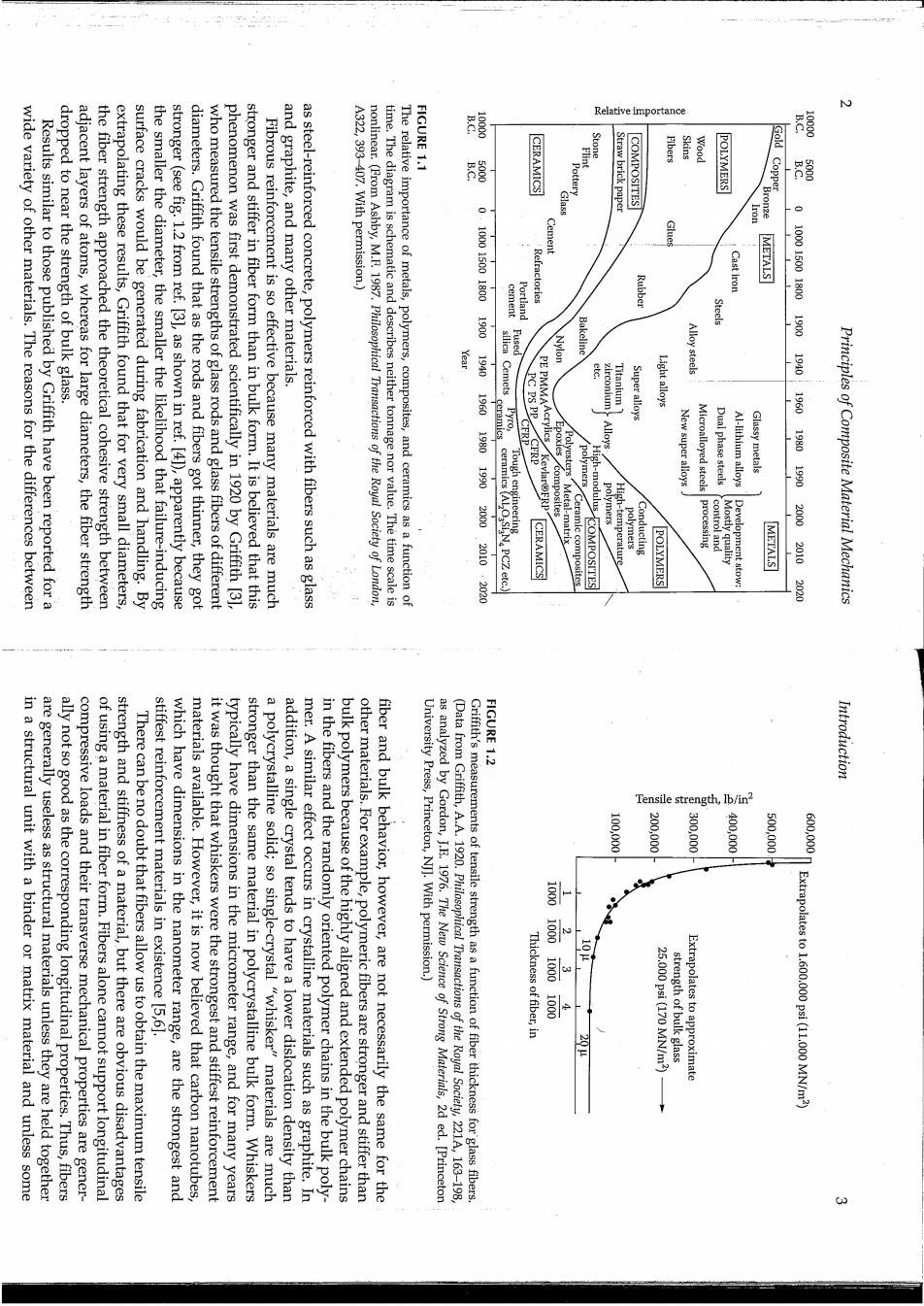

Relative FIGURE 1.1 dropped to near the strength of bulk glass. 馨 CERAMICS Straw brick paper COMPOSITES Fibers POLYMERS 囂 wide variety of other materials.The reasons for the differences between Results similar to those published by Griffith have been reported for a adjacent layers of atoms,whereas for large diameters,the fiber strength the fiber strength approached the theoretical cohesive strength between extrapolating these results,Griffith found that for very small diameters, surface cracks would be generated during fabrication and handling.By the smaller the diameter,the smaller the likelihood that failure-inducing stronger (see fig.1.2 from ref.[3],as shown in ref.[41),apparently because diameters.Griffith found that as the rods and fibers got thinner,they got who measured the tensile strengths of glass rods and glass fibers of different phenomenon was first demonstrated scientifically in 1920 by Griffith [3], stronger and stiffer in fiber form than in bulk form.It is believed that this Fibrous reinforcement is so effective because many materials are much and graphite,and many other materials. as steel-reinforced concrete,polymers reinforced with fibers such as glass A322,393-407.With permission.) nonlinear.(From Ashby,M.F.1987.Philosophical Transactions of the Royal Society of London, time.The diagram is schematic and describes neither tonnage nor value.The time scale is The relative importance of metals,polymers,composites,and ceramics as a function of :1.000150018003001m Cement Refractories METALS Rubber Cast iron Steels Nylon Alloy steels Titanium Super alloys Light alloys 1.60 Pyro, 1P801902000 New super alloys Microalloyed steels Dual phase steels Al-lithium alloys Glassy metals polymers High-temperature polymers Conducting 1.0001500180031900330196901080990200020102020 2010.2020 CERAMICS Ceramic composites POLYMERS processing METALS Principles of Composite Material Mechanics FIGURE 1.2 Introduction in a structural unit with a binder or matrix material and unless some are generally useless as structural materials unless they are held together ally not so good as the corresponding longitudinal properties.Thus,fibers compressive loads and their transverse mechanical properties are gener- of using a material in fiber form.Fibers alone cannot support longitudinal strength and stiffness of a material,but there are obvious disadvantages Tensile strength, Ib/in? There can be no doubt that fibers allow us to obtain the maximum tensile stiffest reinforcement materials in existence 5,6 which have dimensions in the nanometer range,are the strongest and materials available.However,it is now believed that carbon nanotubes, it was thought that whiskers were the strongest and stiffest reinforcement typically have dimensions in the micrometer range,and for many years stronger than the same material in polycrystalline bulk form.Whiskers a polycrystalline solid;so single-crystal "whisker"materials are much addition,a single crystal tends to have a lower dislocation density than mer.A similar effect occurs in crystalline materials such as graphite.In in the fibers and the randomly oriented polymer chains in the bulk poly- bulk polymers because of the highly aligned and extended polymer chains other materials.For example,polymeric fibers are stronger and stiffer than fiber and bulk behavior,however,are not necessarily the same for the University Press,Princeton,NJ].With permission.) as analyzed by Gordon,J.E.1976.The New Science of Strong Materials,2d ed.[Princeton (Data from Griffith,A.A.1920.Philosophical Transactions of the Royal Sociely,221A,163-198, Griffith's measurements of tensile strength as a function of fiber thickness for glass fibers 100000 200000 300.000 00000 500.000 600.0800 Thickness of fiber,in 20P 250002:020M2/me strength of bulk glass Extrapolates to approximate Extrapolates to 1.600.000 psi(11.000 MN/m2)