SOINHO dno sppueig'g oe uosq!5 y pleuox 日0D00D0002- UOSQI9 PRINCIPLES OF COMPOSITE MATERIAL MECHANICS Oht2y 5-0665-h elep-01-dn pue MaN 'sjelelew al!sodwoo go solueyoaw papuedxa pue parepdn sepnjou!joune eul 'spoyau isal pepueis suollel!o eouelajel Mau se llem se 'sas]oJexe yoMewoy -0 NaSI '1xe1 eui inoybno.y

sented at a variety of national and international meetings research have been published in numerous scholarly articles and pre- Engineers and the American Society for Composites.The results of his and the Outstanding Graduate Faculty Mentor Award from Wayne State University.He is an elected Fellow of the American Society of Mechanical of Engineering Outstanding Faculty Award from the University of Idaho, the Distinguished Faculty Fellowship Award,the Devlieg Professorship, secretary.He has been the recipient of the Hetenyi Award for Best Research Paper of the Year from the Society for Experimental Mechanics,the College ment of Material and Process Engineering.He has served the American Society for Composites as its president,vice-president,and membership Society for Composites,the American Society for Testing and Materials, the Society for Experimental Mechanics,and the Society for the Advance- including the American Society of Mechanical Engineers,the American Langley Research Center. Dr.Gibson is an active member of numerous professional societies, and Michigan State University.He has been a development engineer for Union Carbide Corporation and a summer faculty fellow at the NASA visiting faculty positions at Stanford University,the University of Florida, sity of Minnesota.He has held full-time faculty positions at Iowa State University,the University of Idaho,and Wayne State University,and from the University of Florida,his M.S.in mechanical engineering from the University of Tennessee,and his Ph.D.in mechanics from the Univer- of the Advanced Composites Research Laboratory at Wayne State Uni- versity.Dr.Gibson received his B.S.degree in mechanical engineering Ronald F.Gibson is a professor of mechanical engineering and director About the author

器器 为巴 6 的 云 3.2.3 3.2.2 Chapter 3 References..... References... 与 台 茶 5 Improved Mechanics of Materials Models...101 Shear Modulus and Poisson's Ratio....99 Transverse Modulus.......... 3.2.1 Longitudinal Modulus.... Introduction.. 1.1 Basic Concepts.. Contents Elementary Mechanics of Materials Models....91. Fabrication Processes. Eiber-Reinforced Lamina..... Effective Moduli of a Continuous The Generally Orthotropic Lamina..63 The Specially Orthotropic Lamina.. Orthotropic and Isotropic Engineering Constants................... Symmetry in Stress-Strain Relationships....... Effective Moduli in Stress-Strain Relationships..... Chapter 2 Lamina Stress-Strain Relationships........................47 Review of Basic Mechanics of Materials Equations............. Elements of Mechanical Behavior of Composites........ Structural Applications of Composites....... 122 Matrix and Biller Materials..1. Fiber Materials Constituent Materials for Composites...6 Chapter I Introduction Preface to First Edition..xii 三 器 3 齿

品 39 64.2 5.41 6.31 2.21 Chapter 6 References 黑 知 忍 招 References.... 张4 盐 3.5 Introduction.. 47.4 4.33 4.3.2 631 42.3 42.2 42.1 Chapter 4 References...... 3.6 Problems. Modulus Analysis. Stress and Strength Analysis :TT·.…Pr Randomly Oriented Discontinuous Fibers................... 6.3.2 Modulus Analysis. Stress and Strength Analysis.... Off-Axis Aligned Discontinuous Fibers... 6.2.2 Modulus Analysis Stress and Strength Analysis... Aligned Discontinuous Fibers. Analysis of a Discontinuous Fiber-Reinforced Micromechanics Models for Hygrothermal Properties. Hygrothermal Effects........... Lamina Stress-Strain Relationships Including Hygrothermal Degradation of Properties... Chapter 5 Analysis of Lamina Hygrothermal Behavior............ Multiaxial Strength..... Transverse Strength. Longitudinal Strength. Micromechanics Models for Lamina Strength..............147 Quadratic Interaction Criteria Maximum Strain Criterion. Maximum Stress Criterion. Multiaxial Strength Criteria... Introduction........ Strength of a Continuous Fiber-Reinforced Semiempirical Models....... Principles of Composite Material Mechanics B 总 尽 芳 宝 202 学 三 奇 总 三 至 三 芦 三 s 后 后 12 品 动 云 品 品 3 References........ References...... 5.5 易 Contents Problems.. ..1 7.8.2 7.81 7.6.3 7.6.1 7.5 24.3 房 Problems... 5.51 7.11.2 Composite Grid Structures.... Structures...... Application of Laminate Analysis to Composite Selection of Laminate Designs. 7.9.2 Buckling Analysis. Analysis of Small Transverse Deflections Deflection and Buckling of Laminates. 花…::花!:…:。g2g De Due to In-Plane Stresses. Configurations....... First Ply Failure and Subsequent Ply Failures Laminate Strength Analysis. Laminate Hygrothermal Expansion Coefficients Hygrothermal Stresses in Laminates Hygrothermal Degradation of Laminates Hygrothermal Effects in Laminates. Compliances. Comparison of Measured and Predicted Equations... Determination of Laminate Engineering Constants....... Determination of Lamina Stresses and Strains........... Inversion of Laminate Force-Deformation Derivation and Use of Laminate Compliances Quasi-Isotropic Laminates. Antisymmetric Laminates Symmetric Laminates Stiffness Characteristics of Selected Laminate Theory of Laminated Plates with Coupling... Theory of Laminated Beams in Pure Flexure........................ 5R0aEa005: Chapter 7 Analysis of Laminates................ 6.5.2 Modulus Analysis. Strength Analysis. Nanofibers and Nanotubes ··359 355 326 342 335 310 常 常 罩 常 紫 三 虽 的 的 芦 26L

三 常 点 3 器 彩 10.34 10.3.3 10.3.2 10.3.1 References.......... 2.23 922 9.21 References........ 8.3.3 8.32 8.2.6 8.2.5 3.2.4 8.2.3 3.2.2 821 Shear Tests....... 0520H0002050040. …T Measurement of Basic Composite Properties.................... 10.2.3 Constituent Volume Fraction Measurement................ 10.2.2 Neat Resin Matrix Tests 10.2.1 Fiber Tests.................. Measurement of Constituent Material Properties. Introduction....... and Their Constituents.... Chapter 10 Mechanical Testing of Composites Stress Fracture Criteria for Through-Thickness Notches.............. Virtual Crack Closure Technique. Strain Energy Release Rate Approach....................... Stress Intensity Factor Approach.. Fracture Mechanics Analyses of Through-Thickness Cracks........ Chapter 9 Analysis of Fracture........ 8.3.4 Analysis of Damping in Composites...... Transverse Vibration of Laminated Plates.................. Flexural Vibration of Composite Beams.... in Specially Orthotropic Composite Bars................. 8.3.1 Longitudinal Wave Propagation and Vibrations Dynamic Behavior of Composites... 8.1 Introduction............ : Temperature and Aging Bffects....... Blastic-Viscoelastic Correspondence Principle........... Sinusoidal Oscillations and Complex Modulus Quasi-Elastic Analysis......... Differential Equations and Spring-Dashpot Models...... and Relaxation....... Boltzmann Superposition Integrals for Creep Linear Viscoelastic Behavior of Composites Chapter 8 Analysis of Viscoelastic and Dynamic Behavior.....377 Principles of Composite Material Mechanics 密 3 513 贯 517 君 51O 君 爱 三 专 艺 5 紫 芬 雪 考 齿 发 书 E 发 邕 多 第 出 等 Appendix A References... 10.5 104. Contents Appendix B Strain-Displacement Equations .................... Problems........ Stress Equilibrium Equations ................... Measurement of Viscoelastic and Dynamic Properties. 10.3.6 Fiber/Matrix Interface Tests....... 图 ·569 两 罢 留 茶

required. pedagogical approach is to introduce first basic laminate concepts by directly into classical lamination theory,I have concluded that a better Jones.However,rather than beginning the study of laminates by jumping by Ashton,Halpin,and Petit,and Mechanics of Composite Materials by with that of previous textbooks such as the Primer on Composite Materials in Chapter 2 and the classical lamination theory in Chapter 7 is consistent relationships and transformation of properties for anisotropic materials terminology and nomenclature.For example,the coverage of stress-strain the 1960s and 1970s,and,where possible,I have tried to use the accepted have not changed since the first books on the subject were published in Some of the basic elements of composite mechanics covered in this book ticity,and partial differential equations are recommended,but not level material,earlier courses in advanced mechanics of materials,elas- ous exposure to linear algebra is highly desirable.For some of the graduate- to materials engineering,and ordinary differential equations,and previ- ties for the course are knowledge of mechanics of materials,introduction the basis for a two-quarter sequence by omitting some topics.Prerequisi- and which I have taught for the last four years.The book could also be second one-semester course,which is taken only by graduate students, journals and student research projects/presentations,form the basis of a 15 years.Chapters 8 through 10,along with selected papers from technical level course in mechanical engineering,which I have taught for the last Chapters 1 through 7 form the basis of a one-semester senior/graduate- introductory level all led to my decision to write this book. engineers,and the need for a new composite mechanics textbook at the the interdisciplinary nature of the subject,the need to re-educate practicing neers and for reference.The high level of interest in composite materials, new engineers,but also for the continuing education of practicing engi- posite material mechanics should be useful not only for the education of ing engineers to have had no training in this area,so a textbook in com- oriented.Composite materials technology is new enough for many work- aspects of composites.Principles of Composite Material Mechanics is mechanics subject tend to emphasize either the mechanics or the materials science of students taking courses in this area is steadily increasing.Books on the Composite materials is truly an interdisciplinary subject,and the number Preface to First Edition

composite mechanics courses at lowa State University,the University of with them.The notes leading to this book were developed by teaching owe much of my understanding of composite mechanics to interactions Robert Sierakowski and Shive Chaturvedi at the University of Florida.I pleasure of spending a one-year leave working with C.T.and his colleagues began a long and productive association with C.T.Sun,and later had the After beginning my academic career at Iowa State University in 1975,I ultimately led to my career in university teaching and research. cemented my desire to continue working in the composites area and composites with Robert Plunkett at the University of Minnesota further education.My doctoral research on vibration damping characteristics of ence on my later career decision to emphasize composites research and the mechanical development group in Oak Ridge have had a strong influ- tions.My experiences working with Dean Waters and other colleagues in rotating equipment are numerous,as is the case in many other applica- ment.At that time I realized that the advantages of using composites in involved in the design and development of high-speed rotating equip- now part of Oak Ridge National Laboratory in Tennessee,where I.was composites began in 1965 with my first engineering position in what is remiss if I 'did not mention at least some of them.My fascination with 25 years of interactions with colleagues and students,and I would be The contents of this book represent the cumulative effects of more than of them related to practical composite structures,are also included. lished.A variety of example problems and homework problems,a number did not exist when the early mechanics of composites books were pub- maries of the most important ASTM standard test methods,many of which experimental mechanics of composites has been expanded to include sum- ture in Chapter 9,and mechanical testing in Chapter 10.The coverage of Chapter 6,viscoelastic behavior and dynamic behavior in Chapter 8,frac- as hygrothermal effects in Chapter 5,discontinuous fiber composites in with my own notes.Thus,I have added coverage of such important topics decades have made it increasingly necessary to supplement these books numerous new developments in composite mechanics over the last two Although many basic concepts have been presented in earlier textbooks, behavior in Chapter 8. in Chapter 2 to their use in the analysis of viscoelastic and dynamic Thus,effective modulus concepts are emphasized from their introduction for the proper development of heterogeneous composite micromechanics. books such as Mechanics of Composite Materials by Christensen,is essential geneous material,which had previously been covered only in advanced believe that the concept of an effective modulus of an equivalent homo- using the simpler theory of laminated beams in pure flexure.Also,I Principles of Composite Material Mechanics done it without her love,encouragement,patience,and understanding. supporter as I labored on this project,and there is no way that I could have Finally,my wife and best friend,Maryanne,has been my strongest Clarkson University. A&M University;C.T.Sun,University of Florida;and Steven W.Yurgartis, University;John M.Kennedy,Clemson University;Vikram K.Kinra,Texas Chaturvedi,Ohio State University;Vincent Choo,New Mexico State Oklahoma;Olivier A.Bauchau,Rensselaer Polytechnic Institute;Shive many helpful comments and suggestions:Charles W.Bert,University of McGraw-Hill and I would like to thank the following reviewers for their pany,and the Ford Motor Company have been particularly important. National Science Foundation,the Army Research Office,the Boeing Com- book possible.Grants from the Air Force Office of Scientific Research,the numerous funding agencies over the years has also helped to make this particularly important.Generous support for my composites research from port and encouragement of my department chairman,Ken Kline,has been Research Laboratory there in 1989,is gratefully acknowledged.The sup- Ronald F.Gibson University,which made it possible to establish the Advanced Composites several of the figures in Chapter 1.The strong support of Wayne State Research Laboratory,for his encouragement and support and for providing comments.I am grateful to Carl Johnson,also of the Ford Scientific I am indebted to John for his careful review of the manuscript and helpful Ford Scientific Research Laboratory has proved to be very rewarding,and recently,my collaboration with John Sullivan and his colleagues of the whom I team-taught a course on advanced mechanics of composites.Most Particularly important was the interaction with Cornelius Horgan,with his colleages for our many stimulating discussions during that year. Michigan State University in 1987,and I am indebted to Larry Drzal and Serious work on this book actually began during a sabbatical leave at uate students at the University of Idaho. Suarez,Lyle Deobald,Raju Mantena,and Jimmy Hwang,all former grad- has been referred to in this book.I am particularly indebted to Stalin ing of composite mechanics,and the work of several of those students students over the years has contributed immeasurably to my understand- finding the inevitable errors in my notes.Interaction with my graduate students at Wayne State University have been particularly effective at and helped me to "debug"these notes over the years.Most recently,my State University,and I am indebted to the students who took my classes Idaho,the University of Florida,Michigan State University,and Wayne Preface to First Edition

been cited throughout. Preface for her love,encouragement,patience,and understanding. has continued to be my strongest supporter,and I will be forever grateful edition.And as with the first edition,my wife and best friend,Maryanne, findings have enabled me to add important new dimensions in the second tifying the inevitable errors in the first edition,and their thesis research this project.My graduate students have been particularly helpful in iden- granting me sabbatical leaves,which were essential to the completion of students,and sponsors.I am grateful to Wayne State University for pro- sively updated to include coverage of both new and revised ASTM stan- Chapter 10 on testing of composites and their constituents has been exten- of the finite element implementation of the virtual crack closure technique. nomenological approach to understanding linear viscoelastic behavior of Wide Failure Exercise.Chapter 8 has been improved by adding a phe- 4 on strength analysis has been updated to include results from the World librium equations and strain-displacement relations from elasticity the- structures.To strengthen the emphasis on the basic principles of mechanics, Ronald F.Gibson viding a nurturing'environment for my teaching and research,and for As with the first edition,I am indebted to many colleagues,graduate problems have been added to most chapters,and new references have dard test methods.Finally,more example problems and homework composites.Chapter 9 on fracture has been updated to include coverage more detailed discussions of elasticity and finite element models.Chapter ory.Coverage of micromechanics in Chapter 3 has been revised to include the Introduction,and appendices covering the derivations of stress equi- I have added a review of the basic mechanics of materials equations in to nanocomposites,composite grid structures,and composite sandwich edition has new sections on recent applications of composite mechanics since the first edition of this book was published.Accordingly,the second There have been many developments in mechanics of composite materials

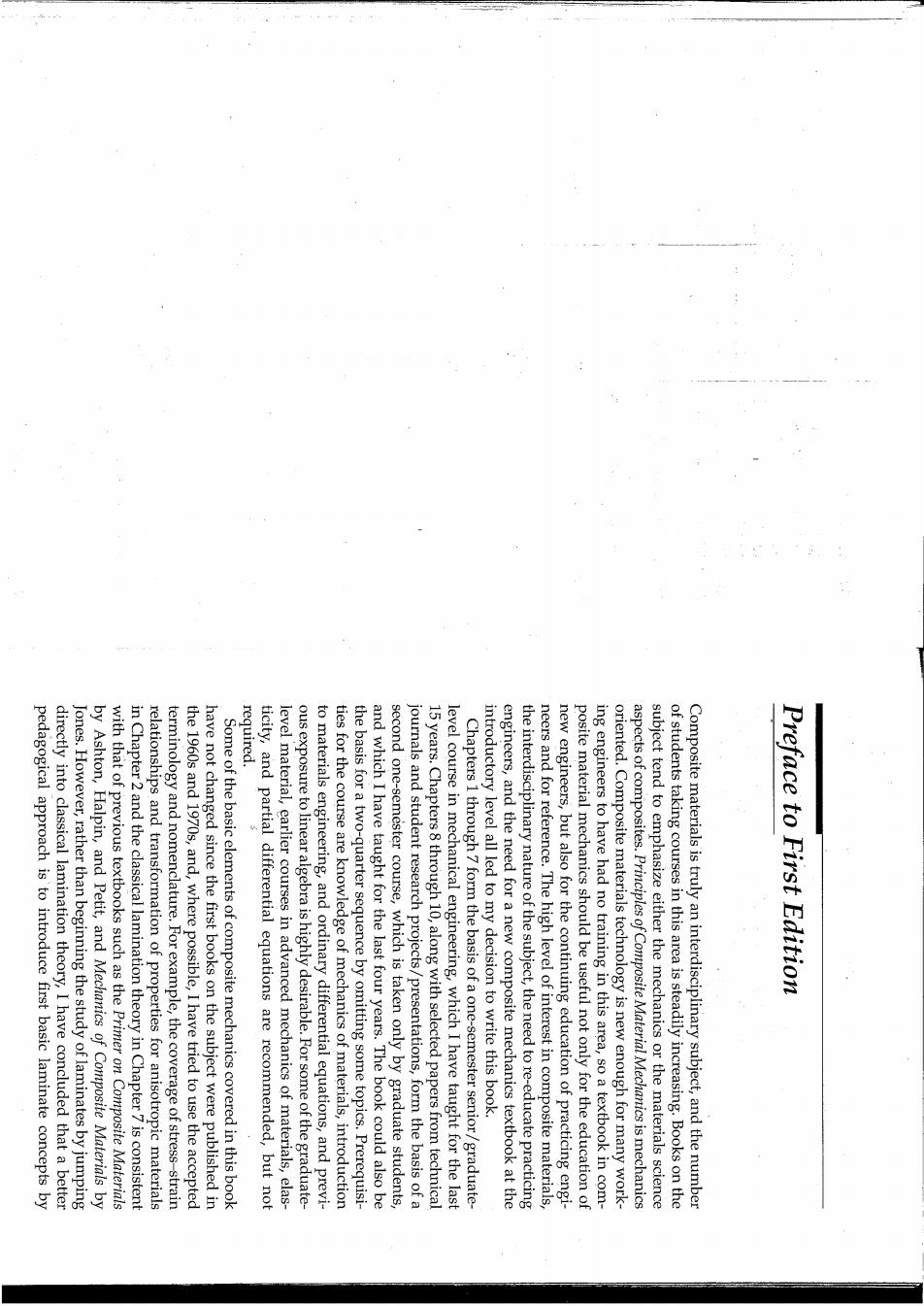

reinforcement.Much later,humans developed structural composites such keep the clay from cracking during drying rather than on structural fibrous reinforcement,however,were probably based on the desire to America apparently used plant fibers in their pottery.These early uses of bricks used by the Israelites.The early natives of South and Central examples of man-made fibrous composites,the straw-reinforced clay Exodus in the Old Testament recorded what surely must be one of the first collagen fibrils in a protein-calcium phosphate matrix [2].The book of whereas most mammalian bone is made up of layered and oriented examples.Wood consists mainly of fibrous cellulose in a matrix of lignin first learned about fibrous composites,nature provides us with numerous Although it is difficult to say with certainty when or where humans but they are generally not so effective as fibers. binder or matrix material.Particle or flake reinforcements are also used, is the fibrous composite consisting of reinforcing fibers embedded in a any of the constituent materials acting alone.The most common example used because they have desirable properties that cannot be achieved by and ceramics and the decreasing role of metals.Composites are generally clearly shows the steadily increasing importance of polymers,composites, has been presented by Ashby [11,as shown schematically in figure 1.1 that The relative importance of the four basic materials in a historical context such as carbon nanotubes. interest in "nanocomposites"having nanometer-sized reinforcements, steadily decreased in size.Most recently,there has been considerable decades,the constituent materials,particularly the reinforcement materials, macroscopic.As composites technology advanced over the last few of modern man-made composite materials,the constituents were typically from various combinations of the other three materials.In the early days more separate materials combined in a structural unit,are typically made polymers,ceramics,and composites.Composites,which consist of two or Structural materials can be divided into four basic categories:metals, Basic Concepts Introduction

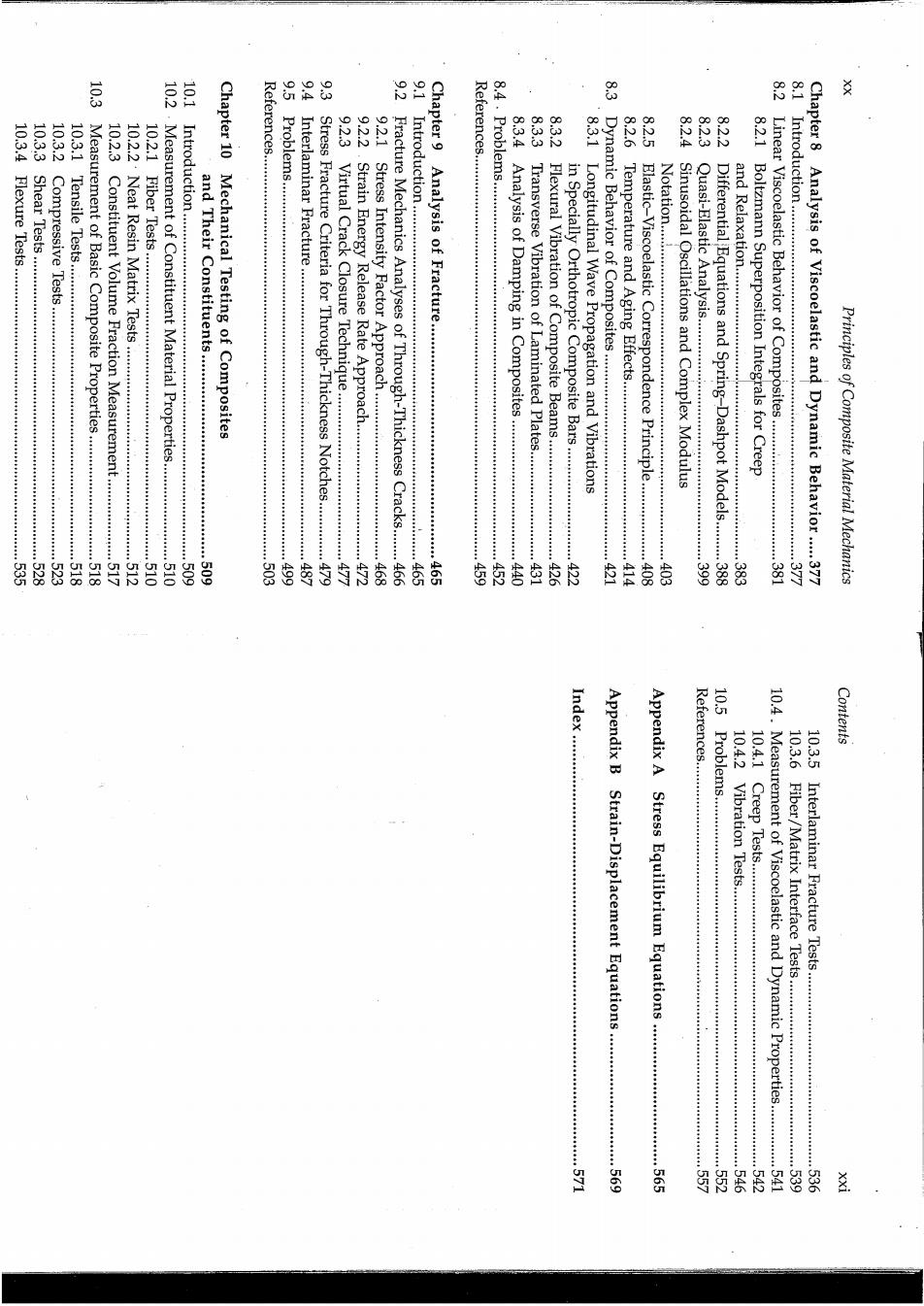

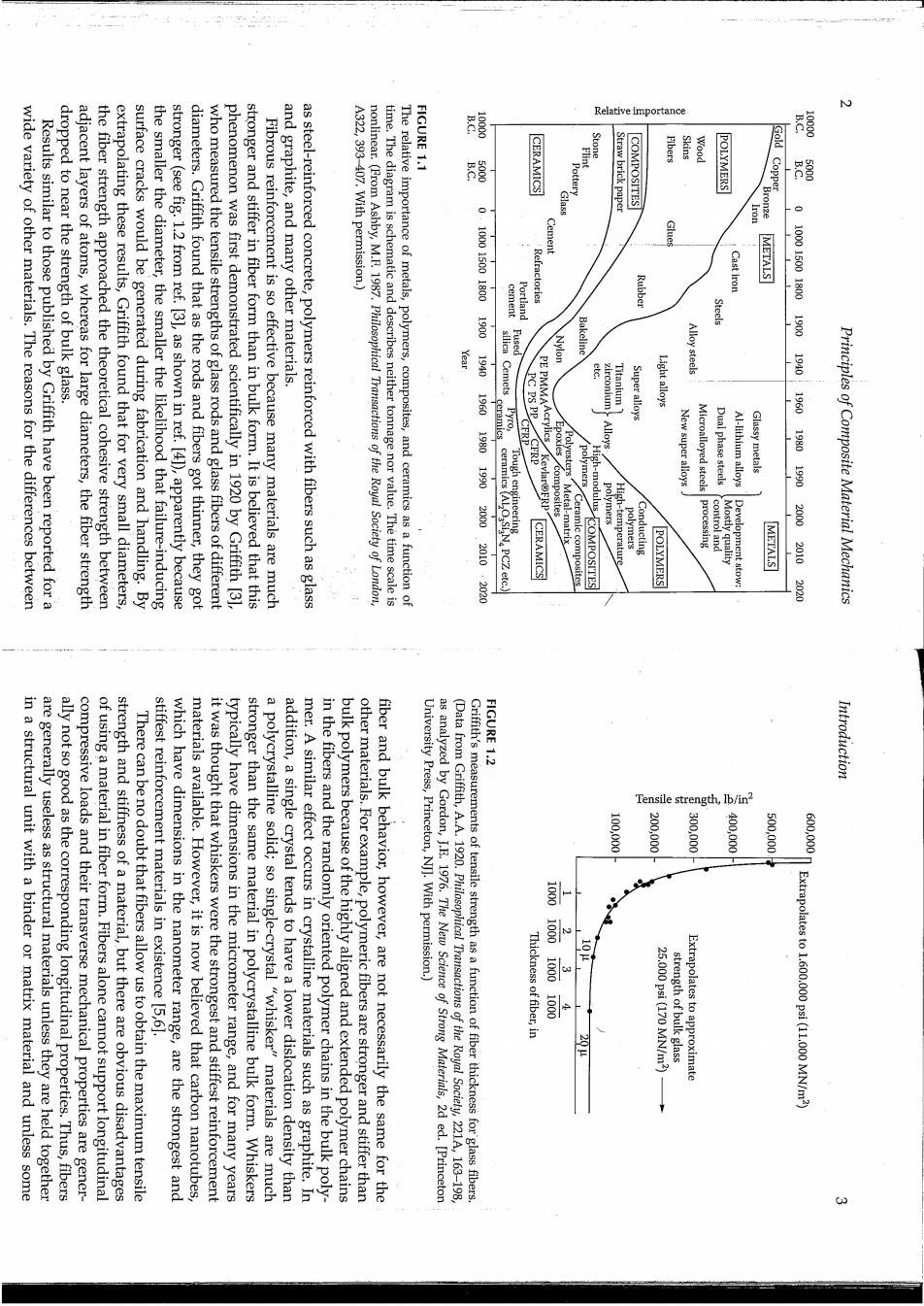

Relative FIGURE 1.1 dropped to near the strength of bulk glass. 馨 CERAMICS Straw brick paper COMPOSITES Fibers POLYMERS 囂 wide variety of other materials.The reasons for the differences between Results similar to those published by Griffith have been reported for a adjacent layers of atoms,whereas for large diameters,the fiber strength the fiber strength approached the theoretical cohesive strength between extrapolating these results,Griffith found that for very small diameters, surface cracks would be generated during fabrication and handling.By the smaller the diameter,the smaller the likelihood that failure-inducing stronger (see fig.1.2 from ref.[3],as shown in ref.[41),apparently because diameters.Griffith found that as the rods and fibers got thinner,they got who measured the tensile strengths of glass rods and glass fibers of different phenomenon was first demonstrated scientifically in 1920 by Griffith [3], stronger and stiffer in fiber form than in bulk form.It is believed that this Fibrous reinforcement is so effective because many materials are much and graphite,and many other materials. as steel-reinforced concrete,polymers reinforced with fibers such as glass A322,393-407.With permission.) nonlinear.(From Ashby,M.F.1987.Philosophical Transactions of the Royal Society of London, time.The diagram is schematic and describes neither tonnage nor value.The time scale is The relative importance of metals,polymers,composites,and ceramics as a function of :1.000150018003001m Cement Refractories METALS Rubber Cast iron Steels Nylon Alloy steels Titanium Super alloys Light alloys 1.60 Pyro, 1P801902000 New super alloys Microalloyed steels Dual phase steels Al-lithium alloys Glassy metals polymers High-temperature polymers Conducting 1.0001500180031900330196901080990200020102020 2010.2020 CERAMICS Ceramic composites POLYMERS processing METALS Principles of Composite Material Mechanics FIGURE 1.2 Introduction in a structural unit with a binder or matrix material and unless some are generally useless as structural materials unless they are held together ally not so good as the corresponding longitudinal properties.Thus,fibers compressive loads and their transverse mechanical properties are gener- of using a material in fiber form.Fibers alone cannot support longitudinal strength and stiffness of a material,but there are obvious disadvantages Tensile strength, Ib/in? There can be no doubt that fibers allow us to obtain the maximum tensile stiffest reinforcement materials in existence 5,6 which have dimensions in the nanometer range,are the strongest and materials available.However,it is now believed that carbon nanotubes, it was thought that whiskers were the strongest and stiffest reinforcement typically have dimensions in the micrometer range,and for many years stronger than the same material in polycrystalline bulk form.Whiskers a polycrystalline solid;so single-crystal "whisker"materials are much addition,a single crystal tends to have a lower dislocation density than mer.A similar effect occurs in crystalline materials such as graphite.In in the fibers and the randomly oriented polymer chains in the bulk poly- bulk polymers because of the highly aligned and extended polymer chains other materials.For example,polymeric fibers are stronger and stiffer than fiber and bulk behavior,however,are not necessarily the same for the University Press,Princeton,NJ].With permission.) as analyzed by Gordon,J.E.1976.The New Science of Strong Materials,2d ed.[Princeton (Data from Griffith,A.A.1920.Philosophical Transactions of the Royal Sociely,221A,163-198, Griffith's measurements of tensile strength as a function of fiber thickness for glass fibers 100000 200000 300.000 00000 500.000 600.0800 Thickness of fiber,in 20P 250002:020M2/me strength of bulk glass Extrapolates to approximate Extrapolates to 1.600.000 psi(11.000 MN/m2)