正在加载图片...

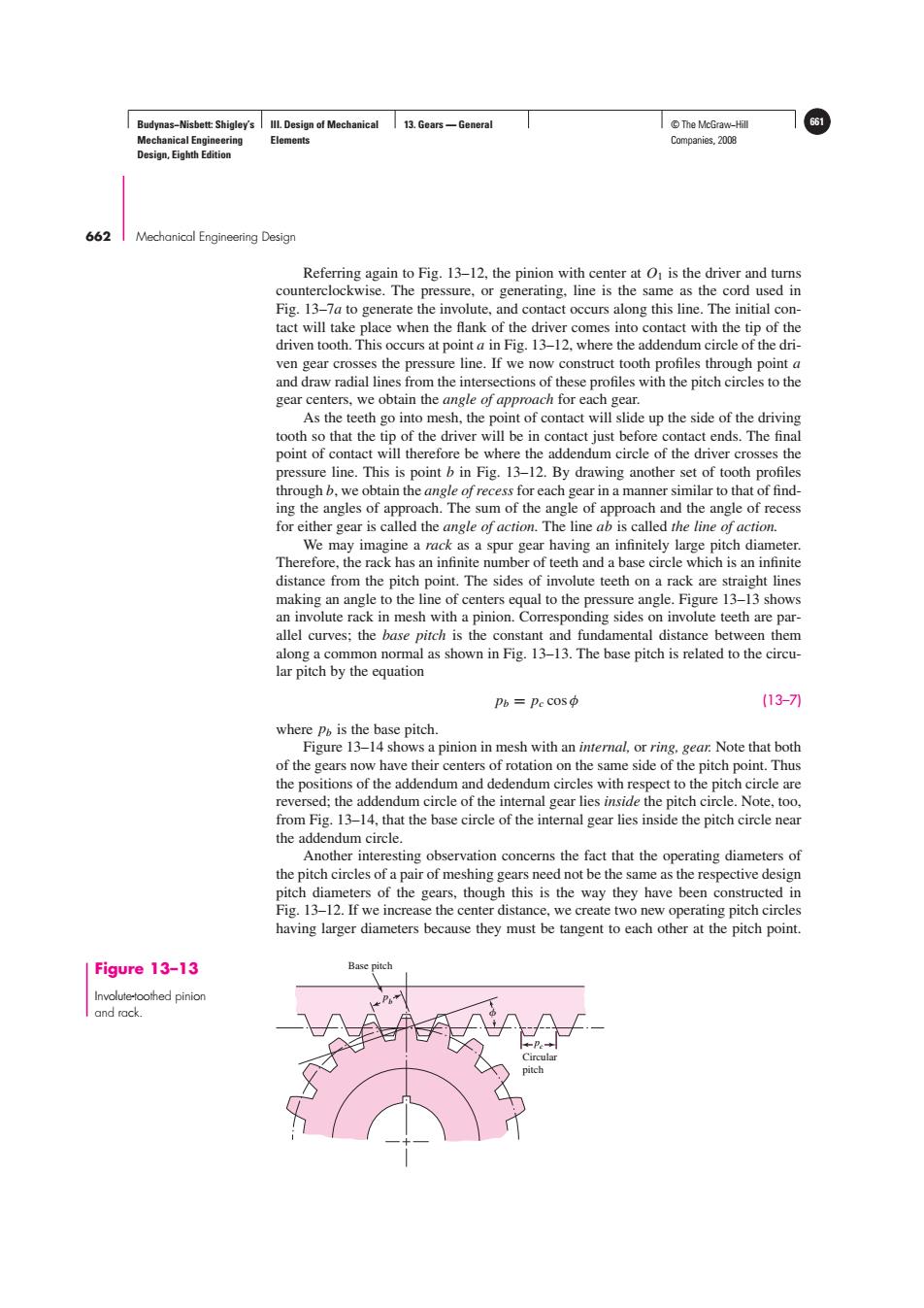

Budynas-Nisbett:Shigley's Ill.Design of Mechanical 13.Gears-General T©The McGraw-Hill 661 Mechanical Engineering Elements Companies,2008 Design,Eighth Edition 662 Mechanical Engineering Design Referring again to Fig.13-12,the pinion with center at O is the driver and turns counterclockwise.The pressure,or generating,line is the same as the cord used in Fig.13-7a to generate the involute,and contact occurs along this line.The initial con- tact will take place when the flank of the driver comes into contact with the tip of the driven tooth.This occurs at point a in Fig.13-12,where the addendum circle of the dri- ven gear crosses the pressure line.If we now construct tooth profiles through point a and draw radial lines from the intersections of these profiles with the pitch circles to the gear centers,we obtain the angle of approach for each gear. As the teeth go into mesh,the point of contact will slide up the side of the driving tooth so that the tip of the driver will be in contact just before contact ends.The final point of contact will therefore be where the addendum circle of the driver crosses the pressure line.This is point b in Fig.13-12.By drawing another set of tooth profiles through b,we obtain the angle of recess for each gear in a manner similar to that of find- ing the angles of approach.The sum of the angle of approach and the angle of recess for either gear is called the angle of action.The line ab is called the line of action. We may imagine a rack as a spur gear having an infinitely large pitch diameter. Therefore,the rack has an infinite number of teeth and a base circle which is an infinite distance from the pitch point.The sides of involute teeth on a rack are straight lines making an angle to the line of centers equal to the pressure angle.Figure 13-13 shows an involute rack in mesh with a pinion.Corresponding sides on involute teeth are par- allel curves;the base pitch is the constant and fundamental distance between them along a common normal as shown in Fig.13-13.The base pitch is related to the circu- lar pitch by the equation Pb=Pe cos中 (13-7 where p is the base pitch. Figure 13-14 shows a pinion in mesh with an internal,or ring,gear.Note that both of the gears now have their centers of rotation on the same side of the pitch point.Thus the positions of the addendum and dedendum circles with respect to the pitch circle are reversed;the addendum circle of the internal gear lies inside the pitch circle.Note,too, from Fig.13-14,that the base circle of the internal gear lies inside the pitch circle near the addendum circle. Another interesting observation concerns the fact that the operating diameters of the pitch circles of a pair of meshing gears need not be the same as the respective design pitch diameters of the gears,though this is the way they have been constructed in Fig.13-12.If we increase the center distance,we create two new operating pitch circles having larger diameters because they must be tangent to each other at the pitch point. Figure 13-13 Involute-toothed pinion and rack.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 13. Gears — General © The McGraw−Hill 661 Companies, 2008 662 Mechanical Engineering Design Circular pitch Base pitch pc pb Figure 13–13 Involute-toothed pinion and rack. Referring again to Fig. 13–12, the pinion with center at O1 is the driver and turns counterclockwise. The pressure, or generating, line is the same as the cord used in Fig. 13–7a to generate the involute, and contact occurs along this line. The initial contact will take place when the flank of the driver comes into contact with the tip of the driven tooth. This occurs at point a in Fig. 13–12, where the addendum circle of the driven gear crosses the pressure line. If we now construct tooth profiles through point a and draw radial lines from the intersections of these profiles with the pitch circles to the gear centers, we obtain the angle of approach for each gear. As the teeth go into mesh, the point of contact will slide up the side of the driving tooth so that the tip of the driver will be in contact just before contact ends. The final point of contact will therefore be where the addendum circle of the driver crosses the pressure line. This is point b in Fig. 13–12. By drawing another set of tooth profiles through b, we obtain the angle of recess for each gear in a manner similar to that of finding the angles of approach. The sum of the angle of approach and the angle of recess for either gear is called the angle of action. The line ab is called the line of action. We may imagine a rack as a spur gear having an infinitely large pitch diameter. Therefore, the rack has an infinite number of teeth and a base circle which is an infinite distance from the pitch point. The sides of involute teeth on a rack are straight lines making an angle to the line of centers equal to the pressure angle. Figure 13–13 shows an involute rack in mesh with a pinion. Corresponding sides on involute teeth are parallel curves; the base pitch is the constant and fundamental distance between them along a common normal as shown in Fig. 13–13. The base pitch is related to the circular pitch by the equation pb = pc cos φ (13–7) where pb is the base pitch. Figure 13–14 shows a pinion in mesh with an internal, or ring, gear. Note that both of the gears now have their centers of rotation on the same side of the pitch point. Thus the positions of the addendum and dedendum circles with respect to the pitch circle are reversed; the addendum circle of the internal gear lies inside the pitch circle. Note, too, from Fig. 13–14, that the base circle of the internal gear lies inside the pitch circle near the addendum circle. Another interesting observation concerns the fact that the operating diameters of the pitch circles of a pair of meshing gears need not be the same as the respective design pitch diameters of the gears, though this is the way they have been constructed in Fig. 13–12. If we increase the center distance, we create two new operating pitch circles having larger diameters because they must be tangent to each other at the pitch point.�