正在加载图片...

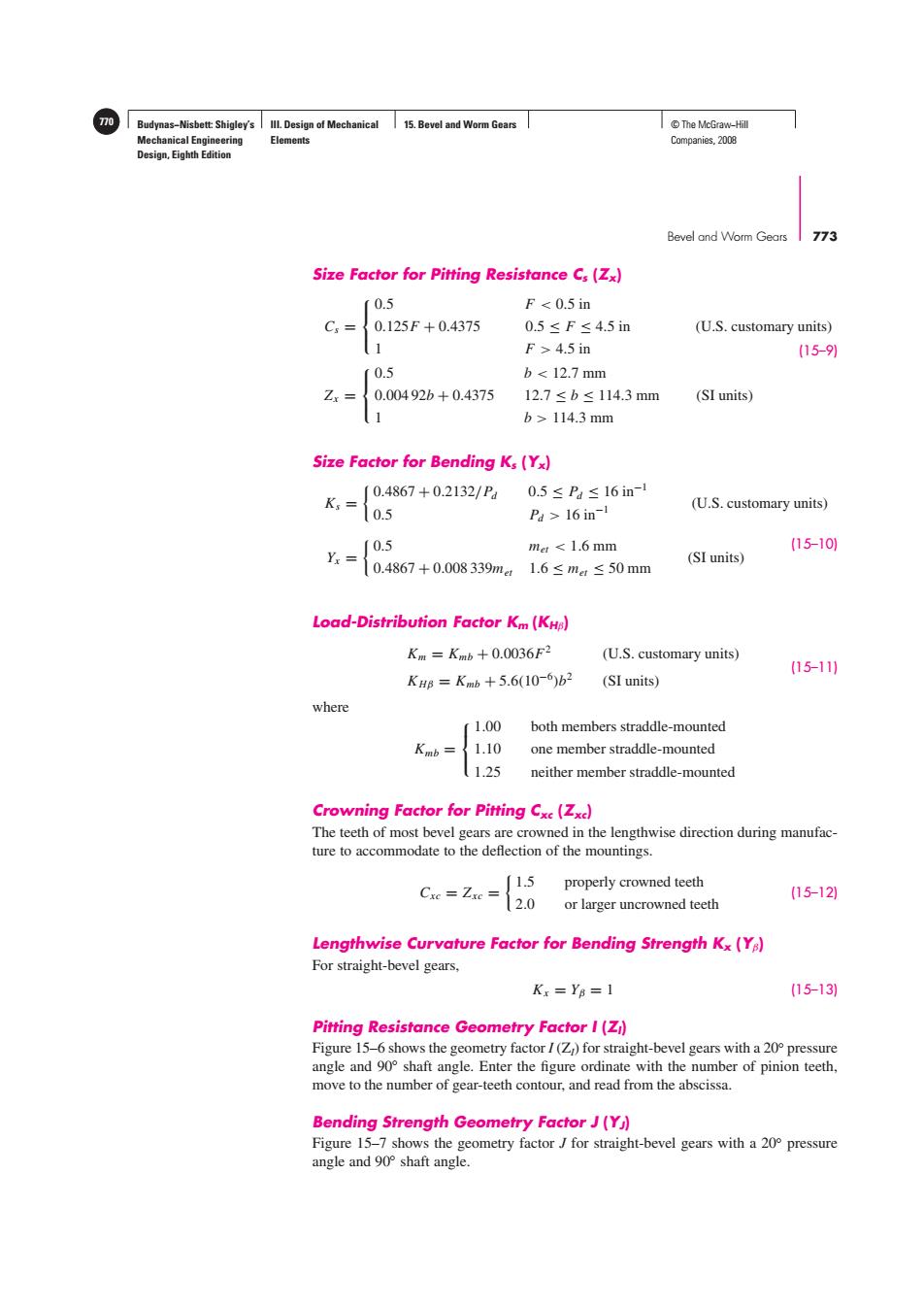

0 Budynas-Nisbett:Shigley's Ill.Design of Mechanical 15.Bevel and Worm Gears T©The McGraw-Hil Mechanical Engineering Elements Companies,2008 Design,Eighth Edition Bevel and Worm Gears 773 Size Factor for Pitting Resistance Cs(Zx) 0.5 F<0.5in C= 0.125F+0.4375 0.5≤F≤4.5in (U.S.customary units) 1 F4.5in (15-91 0.5 b<12.7mm Zx= 0.00492b+0.4375 12.7≤b≤114.3mm (SI units) 1 b>114.3mm Size Factor for Bending Ks (Yx) K,= 0.4867+0.2132/Pa0.5≤P≤16in-1 (U.S.customary units) 0.5 Pa>16 in-1 10.5 mer 1.6 mm (15-101 Yt= 10.4867+0.008339n1.6≤mer≤50mm (SI units) Load-Distribution Factor Km(KHp) Km=Kmb+0.0036F2 (U.S.customary units) (15-111 KHB=Kmb+5.6(10-6)b2 (SI units) where 1.00 both members straddle-mounted Kmb 1.10 one member straddle-mounted 1.25 neither member straddle-mounted Crowning Factor for Pitting Cxe(Zxe) The teeth of most bevel gears are crowned in the lengthwise direction during manufac- ture to accommodate to the deflection of the mountings. 1.5 properly crowned teeth Cxc =Zxc= (15-12) 2.0 or larger uncrowned teeth Lengthwise Curvature Factor for Bending Strength Kx(Ys) For straight-bevel gears, K=Y8=1 (15-13) Pitting Resistance Geometry Factor I(Zi) Figure 15-6 shows the geometry factor /(Z)for straight-bevel gears with a 20 pressure angle and 90 shaft angle.Enter the figure ordinate with the number of pinion teeth, move to the number of gear-teeth contour,and read from the abscissa. Bending Strength Geometry Factor J(Yj) Figure 15-7 shows the geometry factor for straight-bevel gears with a 20 pressure angle and 90 shaft angle.Budynas−Nisbett: Shigley’s Mechanical Engineering Design, Eighth Edition III. Design of Mechanical Elements 15. Bevel and Worm Gears 770 © The McGraw−Hill Companies, 2008 Bevel and Worm Gears 773 Size Factor for Pitting Resistance Cs (Zx) Cs = ⎧ ⎨ ⎩ 0.5 F < 0.5 in 0.125F + 0.4375 0.5 ≤ F ≤ 4.5 in 1 F > 4.5 in (U.S. customary units) Zx = ⎧ ⎨ ⎩ 0.5 b < 12.7 mm 0.004 92b + 0.4375 12.7 ≤ b ≤ 114.3 mm 1 b > 114.3 mm (SI units) (15–9) Size Factor for Bending Ks (Yx) Ks = 0.4867 + 0.2132/Pd 0.5 ≤ Pd ≤ 16 in−1 0.5 Pd > 16 in−1 (U.S. customary units) Yx = 0.5 met < 1.6 mm 0.4867 + 0.008 339met 1.6 ≤ met ≤ 50 mm (SI units) (15–10) Load-Distribution Factor Km (KHβ) Km = Kmb + 0.0036F2 (U.S. customary units) K Hβ = Kmb + 5.6(10−6)b2 (SI units) (15–11) where Kmb = ⎧ ⎨ ⎩ 1.00 both members straddle-mounted 1.10 one member straddle-mounted 1.25 neither member straddle-mounted Crowning Factor for Pitting Cxc (Zxc) The teeth of most bevel gears are crowned in the lengthwise direction during manufacture to accommodate to the deflection of the mountings. Cxc = Zxc = 1.5 properly crowned teeth 2.0 or larger uncrowned teeth (15–12) Lengthwise Curvature Factor for Bending Strength Kx (Yβ) For straight-bevel gears, Kx = Yβ = 1 (15–13) Pitting Resistance Geometry Factor I (ZI) Figure 15–6 shows the geometry factor I (ZI) for straight-bevel gears with a 20◦ pressure angle and 90◦ shaft angle. Enter the figure ordinate with the number of pinion teeth, move to the number of gear-teeth contour, and read from the abscissa. Bending Strength Geometry Factor J (YJ) Figure 15–7 shows the geometry factor J for straight-bevel gears with a 20◦ pressure angle and 90◦ shaft angle