Energy-Efficiency Market Development The Perspective From China Yonghao Luo Shanghai Jiaotong University Visiting Scholar,Battelle Memorial Institute Earth Technologies Forum March25-27,2002 Washington,DC

Energy-Efficiency Market Development The Perspective From China Yonghao Luo Shanghai Jiaotong University Visiting Scholar, Battelle Memorial Institute Earth Technologies Forum March 25-27, 2002 Washington, DC

Outline Potential for Energy Efficiency Obstacles and Opportunities Proposed Solution to Develop Market

Outline ■ Potential for Energy Efficiency ■ Obstacles and Opportunities ■ Proposed Solution to Develop Market

Potential for Energy Efficiency in China

Potential for Energy Efficiency in China

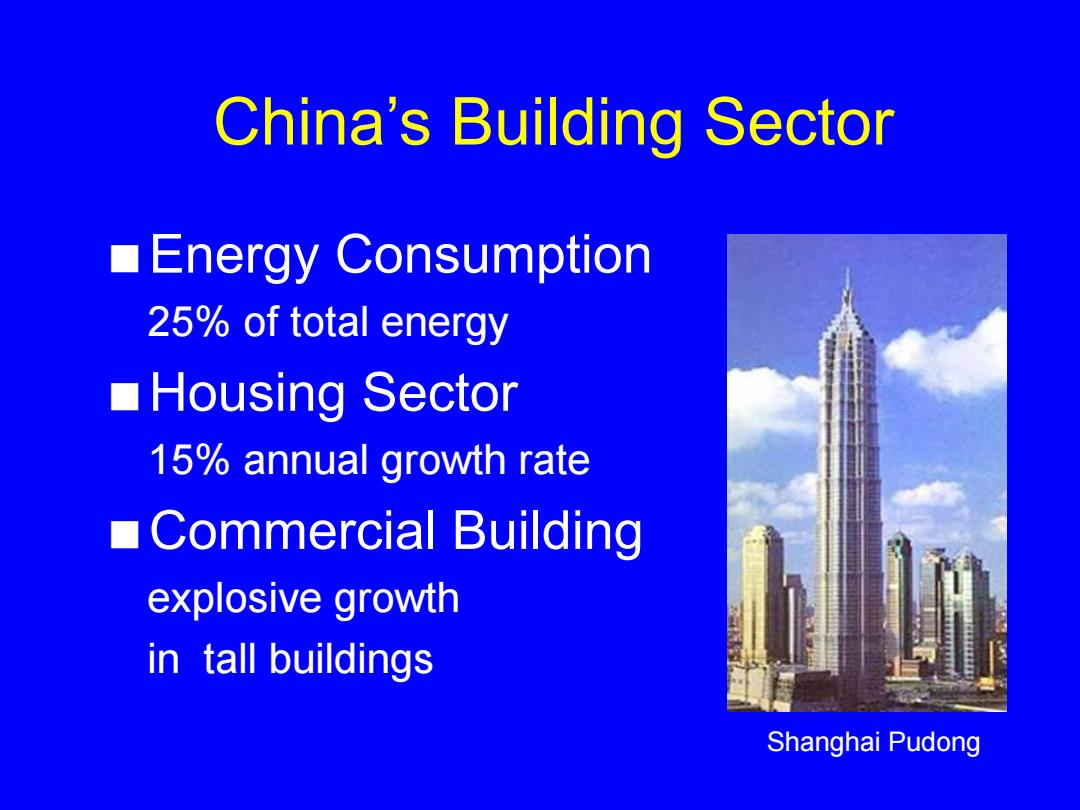

China's Building Sector Energy Consumption 25%of total energy Housing Sector 15%annual growth rate Commercial Building explosive growth in tall buildings Shanghai Pudong

China’s Building Sector Energy Consumption 25% of total energy Housing Sector 15% annual growth rate Commercial Building explosive growth in tall buildings Shanghai Pudong

Building Sector Reform Yangtse River Borderline northern houses are heated (subsidized) Map of China resistance to change Southern Building Envelope Beijing thermal resistance is low Winter Heating inside temperature condition: Yangtse River <Shanghai cold in the winter,0~-5 C hot in the summer,32~35C No Winter Heating Air Conditioning in the South very popular now,large energy loss

Building Sector Reform Yangtse River Borderline northern houses are heated (subsidized) resistance to change Southern Building Envelope thermal resistance is low inside temperature condition: cold in the winter, 0~ -5 ºC hot in the summer, 32~35ºC Air Conditioning in the South very popular now, large energy loss

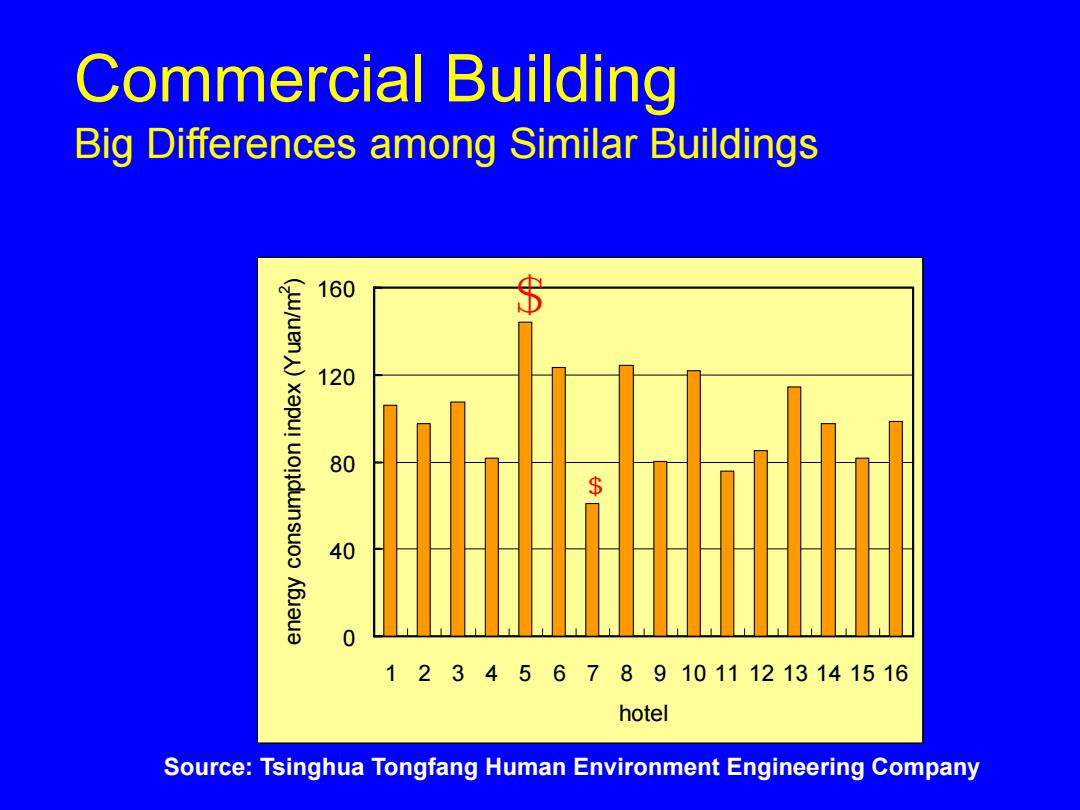

Potential for Energy Conservation in China's Commercial Buildings Energy Consumption is Much Higher than International Norms 188 kwh/m2.a in Beijing 135 kwh/m2.a in Japan Big Difference among Similar Buildings energy audits for 16 luxury hotels in Beijing highest energy consumption intensity is three times the lowest Big Difference between Reality and Potential bad management,lack of automatic systems,and design failures

Potential for Energy Conservation in China’s Commercial Buildings Energy Consumption is Much Higher than International Norms 188 kwh/m2a in Beijing 135 kwh/m2a in Japan Big Difference among Similar Buildings energy audits for 16 luxury hotels in Beijing highest energy consumption intensity is three times the lowest Big Difference between Reality and Potential bad management, lack of automatic systems, and design failures

Commercial Building Big Differences among Similar Buildings 160 120 80 $ 40 0 12345678910111213141516 hotel Source:Tsinghua Tongfang Human Environment Engineering Company

Commercial Building Big Differences among Similar Buildings 0 40 80 120 160 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 hotel e n erg y c o n s u m ptio n in d e x (Y u a n/m 2 ) ﹩ $ Source: Tsinghua Tongfang Human Environment Engineering Company

Commercial Buildings Economic Analysis of Different Improvements Investment Return Return Time Management $1 $10~20 1~2 months Replace Fans and Pumps $1 $0.8≈1.0 1~1.2 years Add Automatic Control Systems $1 $0.3≈0.5 2~3 years Retrofit Whole Systems $1 $0.2~0.4 3~5 years Retrofit Construction Material $1 $0.1~0.2 5~10 years Source:Tsinghua Tongfang Human Environment Engineering Company

Commercial Buildings Economic Analysis of Different Improvements Investment Return Return Time Management $ 1 $ 10~20 1~2 months Replace Fans and Pumps $ 1 $ 0.8~1.0 1~1.2 years Add Automatic Control Systems $ 1 $ 0.3~0.5 2~3 years Retrofit Whole Systems $ 1 $ 0.2~0.4 3~5 years Retrofit Construction Material $ 1 $ 0.1~0.2 5~10 years Source: Tsinghua Tongfang Human Environment Engineering Company

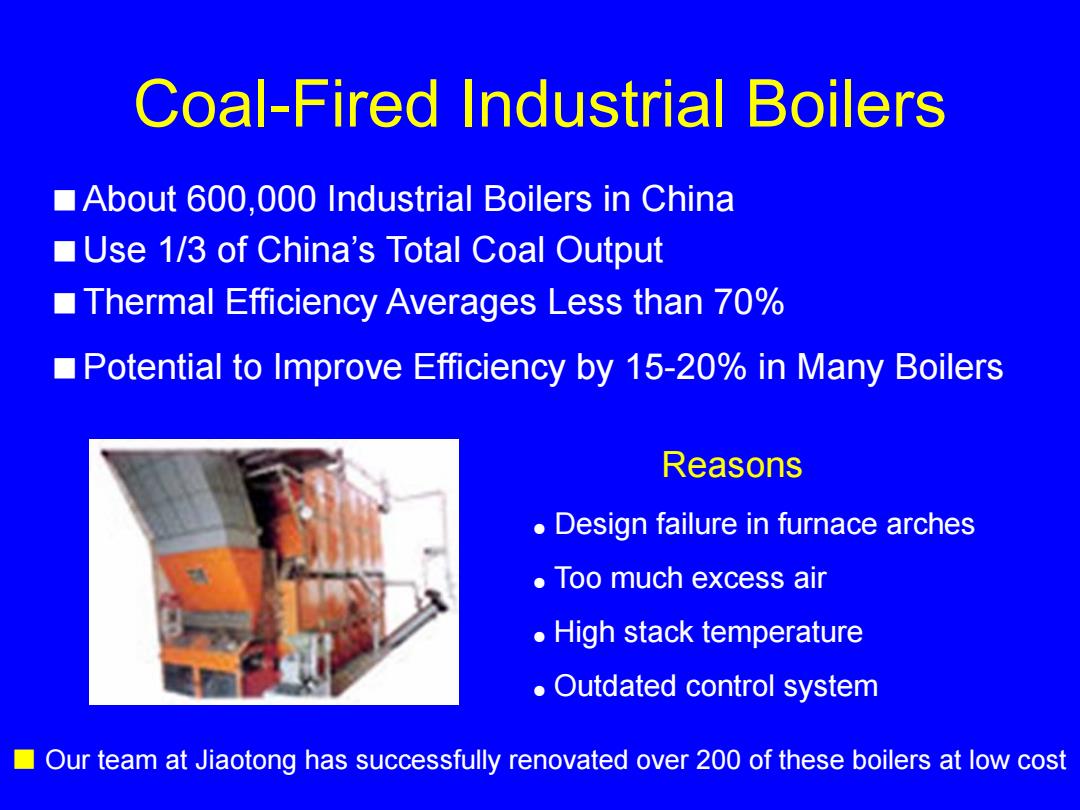

Coal-Fired Industrial Boilers About 600,000 Industrial Boilers in China Use 1/3 of China's Total Coal Output Thermal Efficiency Averages Less than 70% Potential to Improve Efficiency by 15-20%in Many Boilers Reasons Design failure in furnace arches 。Too much excess air High stack temperature Outdated control system Our team at Jiaotong has successfully renovated over 200 of these boilers at low cost

Coal-Fired Industrial Boilers About 600,000 Industrial Boilers in China Use 1/3 of China’s Total Coal Output Thermal Efficiency Averages Less than 70% Potential to Improve Efficiency by 15-20% in Many Boilers Reasons ● Design failure in furnace arches ● Too much excess air ● High stack temperature ● Outdated control system ■ Our team at Jiaotong has successfully renovated over 200 of these boilers at low cost

Industrial Boiler Case Studies (Using Double Herringbone Furnace Arches) A Stoker Boiler in a Paper Mill after retrofitting furnace arches and duct system 。 steam capacity increases from 28t/h to 38t/h can burn cheap,local coal saves about 200,000 RMB per month,1 month ROl A Stoker Boiler in a Shipbuilding Company after retrofitting furnace arches thermal efficiency increases from 69.3%to 77.6% coal saving 2925 t/a;CO2 reduction 5639 t/a 。6 month ROl

Industrial Boiler Case Studies (Using Double Herringbone Furnace Arches) ■ A Stoker Boiler in a Paper Mill after retrofitting furnace arches and duct system ● steam capacity increases from 28t/h to 38t/h ● can burn cheap, local coal ● saves about 200,000 RMB per month, 1 month ROI ■ A Stoker Boiler in a Shipbuilding Company after retrofitting furnace arches ● thermal efficiency increases from 69.3% to 77.6% ● coal saving 2925 t/a; CO2 reduction 5639 t/a ● 6 month ROI