Chapter GEAR TRAINS Cycle and epicycle, orb in orb JOHN MILTON.PARADISE LOST 9 9.0 INTRODUCTION The earliest known reference to gear trains is in a treatise by Hero of Alexandria(c.100 B.C.).Gear trains are widely used in all kinds of mechanisms and machines,from can openers to aircraft carriers.Whenever a change in the speed or torque of a rotating de- vice is needed,a gear train or one of its cousins.the belt or chain drive mechanism,will usually be used.This chapter will explore the theory of gear tooth action and the design of these ubiquitous devices for motion control.The calculations involved are trivial compared to those for cams or linkages.The shape of gear teeth has become quite stan- dardized for good kinematic reasons which we will explore. Gears of various sizes and styles are readily available from many manufacturers. Assembled gearboxes for particular ratios are also stock items.The kinematic design of gear trains is principally involved with the selection of appropriate ratios and gear diam- eters.A complete gear train design will necessarily involve considerations of strength of materials and the complicated stress states to which gear teeth are subjected.This text will not deal with the stress analysis aspects of gear design.There are many texts which do.Some are listed in the bibliography at the end of this chapter.This chapter will dis- cuss the kinematics of gear tooth theory,gear types,and the kinematic design of gearsets and gear trains of simple,compound,reverted,and epicyclic types.Chain and belt drives will also be discussed.Examples of the use of these devices will be presented as well. 432

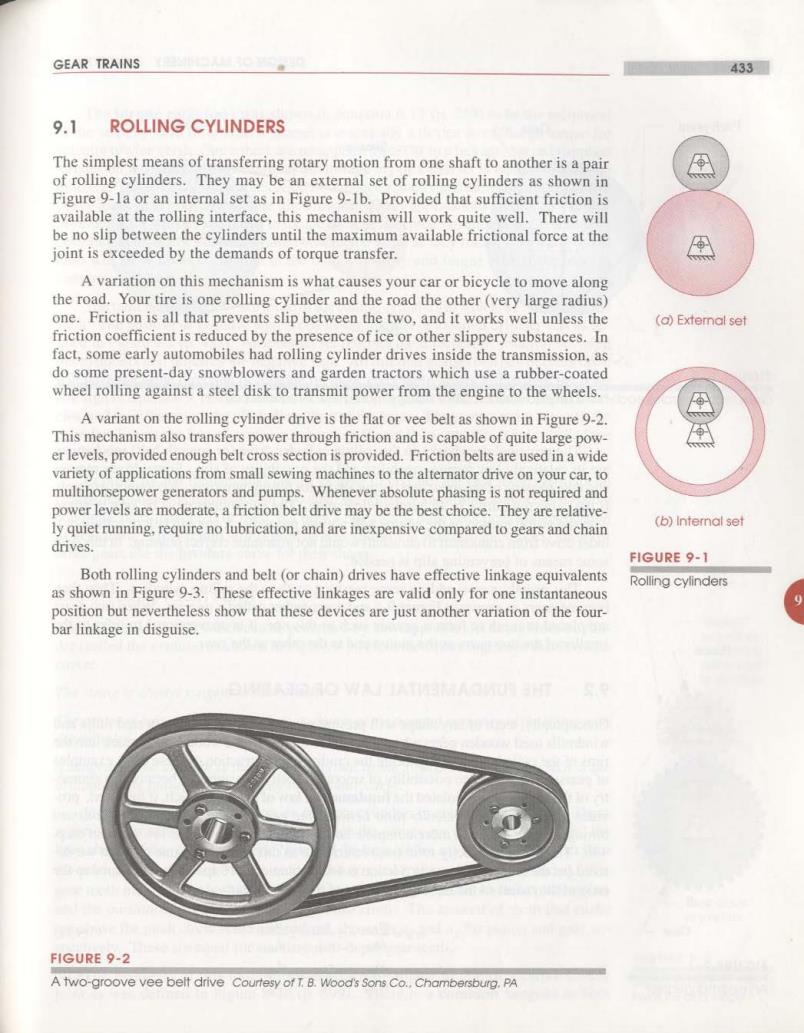

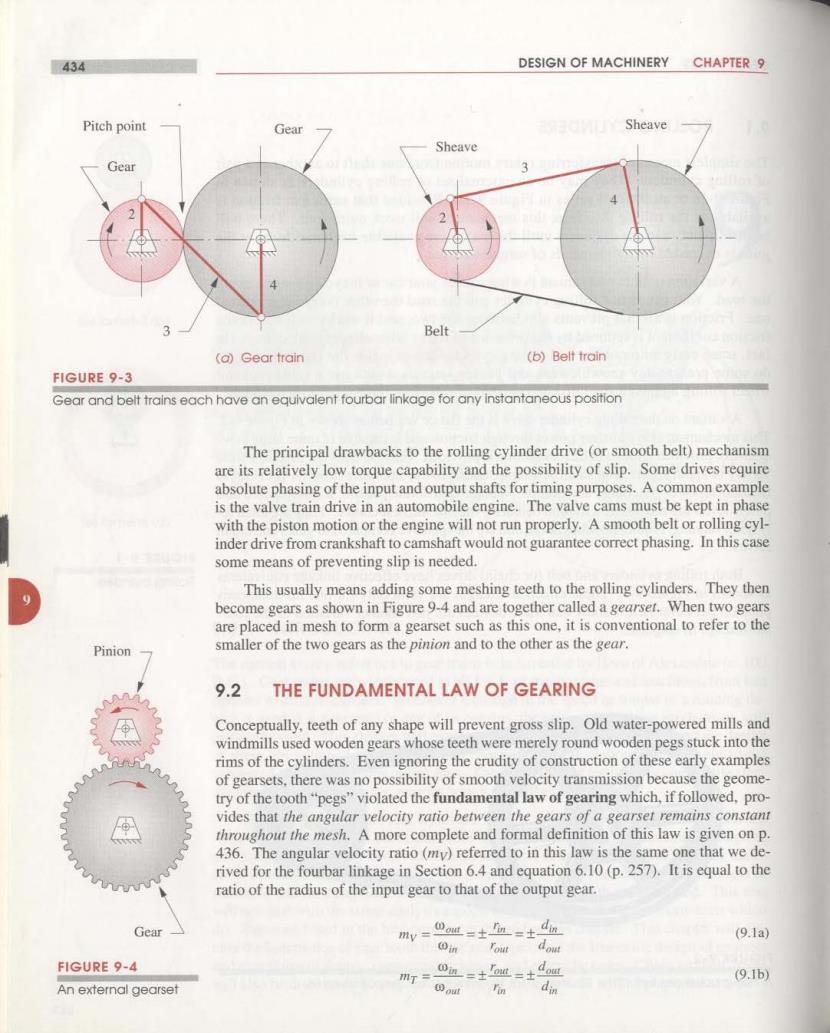

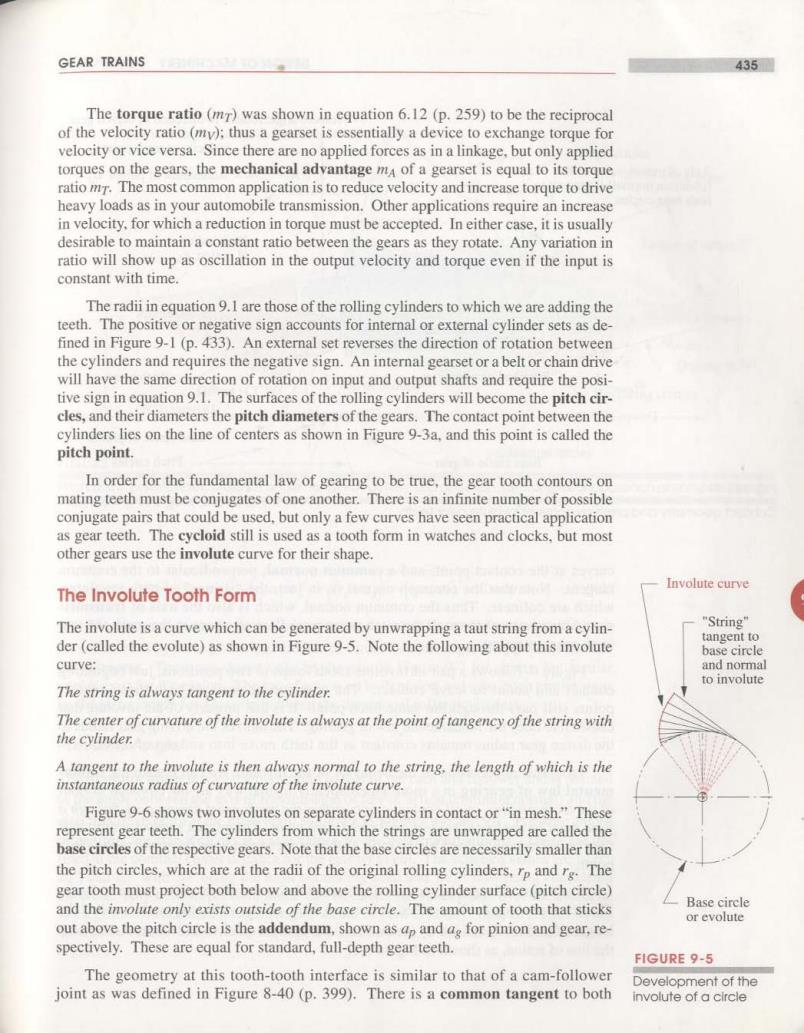

GEAR TRAINS 433 9.1 ROLLING CYLINDERS The simplest means of transferring rotary motion from one shaft to another is a pair of rolling cylinders.They may be an external set of rolling cylinders as shown in Figure 9-1a or an internal set as in Figure 9-1b.Provided that sufficient friction is available at the rolling interface,this mechanism will work quite well.There will be no slip between the cylinders until the maximum available frictional force at the joint is exceeded by the demands of torque transfer. A variation on this mechanism is what causes your car or bicycle to move along the road.Your tire is one rolling cylinder and the road the other(very large radius) one.Friction is all that prevents slip between the two,and it works well unless the (a)Extemal set friction coefficient is reduced by the presence of ice or other slippery substances.In fact,some early automobiles had rolling cylinder drives inside the transmission.as do some present-day snowblowers and garden tractors which use a rubber-coated wheel rolling against a steel disk to transmit power from the engine to the wheels. A variant on the rolling cylinder drive is the flat or vee belt as shown in Figure 9-2. This mechanism also transfers power through friction and is capable of quite large pow- er levels,provided enough belt cross section is provided.Friction belts are used in a wide variety of applications from small sewing machines to the alternator drive on your car,to multihorsepower generators and pumps.Whenever absolute phasing is not required and power levels are moderate,a friction belt drive may be the best choice.They are relative- ly quiet running,require no lubrication,and are inexpensive compared to gears and chain (b)Intemnal set drives. FIGURE 9-1 Both rolling cylinders and belt(or chain)drives have effective linkage equivalents Rolling cylinders as shown in Figure 9-3.These effective linkages are valid only for one instantaneous position but nevertheless show that these devices are just another variation of the four- bar linkage in disguise. FIGURE 9-2 A two-groove vee belt drive Courtesy of T.B.Wood's Sons Co..Chambersburg.PA

434 DESIGN OF MACHINERY CHAPTER 9 Pitch point Gear Sheave Sheave Gear 3 Belt (a)Gear train (b)Belt train FIGURE 9-3 Gear and belt trains each have an equivalent fourbar linkage for any Instantaneous position The principal drawbacks to the rolling cylinder drive (or smooth belt)mechanism are its relatively low torque capability and the possibility of slip.Some drives require absolute phasing of the input and output shafts for timing purposes.A common example is the valve train drive in an automobile engine.The valve cams must be kept in phase with the piston motion or the engine will not run properly.A smooth belt or rolling cyl- inder drive from crankshaft to camshaft would not guarantee correct phasing.In this case some means of preventing slip is needed. This usually means adding some meshing teeth to the rolling cylinders.They then become gears as shown in Figure 9-4 and are together called a gearset.When two gears are placed in mesh to form a gearset such as this one,it is conventional to refer to the Pinion smaller of the two gears as the pinion and to the other as the gear. 9.2 THE FUNDAMENTAL LAW OF GEARING Conceptually,teeth of any shape will prevent gross slip.Old water-powered mills and windmills used wooden gears whose teeth were merely round wooden pegs stuck into the rims of the cylinders.Even ignoring the crudity of construction of these early examples of gearsets.there was no possibility of smooth velocity transmission because the geome- try of the tooth"pegs"violated the fundamental law of gearing which,if followed,pro- vides that the angular velocity ratio between the gears of a gearset remains constant throughout the mesh.A more complete and formal definition of this law is given on p. 436.The angular velocity ratio (my)referred to in this law is the same one that we de- rived for the fourbar linkage in Section 6.4 and equation 6.10(p.257).It is equal to the ratio of the radius of the input gear to that of the output gear. Gear mv=oau=±n=土dm (9.1a) in dowt FIGURE 9-4 功T= 0n=tot=士 out (9.1b) An external gearset out m din

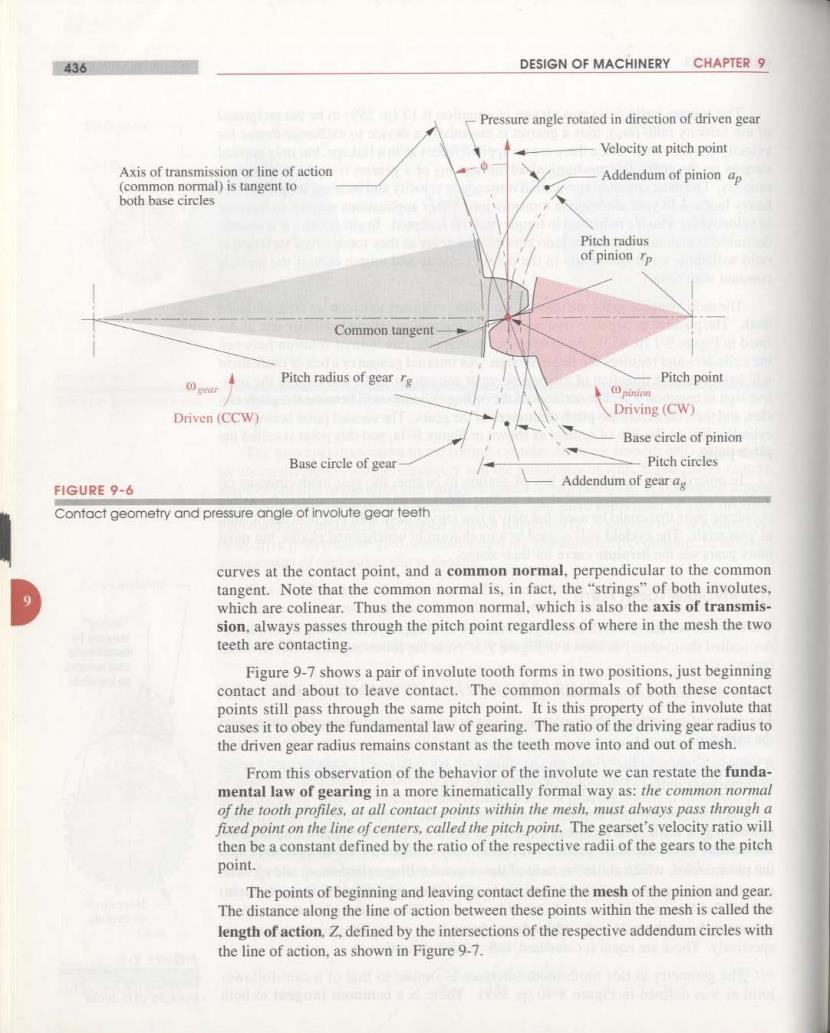

GEAR TRAINS 435 The torque ratio(m)was shown in equation 6.12(p.259)to be the reciprocal of the velocity ratio (my):thus a gearset is essentially a device to exchange torque for velocity or vice versa.Since there are no applied forces as in a linkage,but only applied torques on the gears,the mechanical advantage mA of a gearset is equal to its torque ratio m.The most common application is to reduce velocity and increase torque to drive heavy loads as in your automobile transmission.Other applications require an increase in velocity,for which a reduction in torque must be accepted.In either case,it is usually desirable to maintain a constant ratio between the gears as they rotate.Any variation in ratio will show up as oscillation in the output velocity and torque even if the input is constant with time. The radii in equation 9.I are those of the rolling cylinders to which we are adding the teeth.The positive or negative sign accounts for internal or external cylinder sets as de- fined in Figure 9-1(p.433).An external set reverses the direction of rotation between the cylinders and requires the negative sign.An internal gearset or a belt or chain drive will have the same direction of rotation on input and output shafts and require the posi- tive sign in equation 9.1.The surfaces of the rolling cylinders will become the pitch cir- cles,and their diameters the pitch diameters of the gears.The contact point between the cylinders lies on the line of centers as shown in Figure 9-3a,and this point is called the pitch point. In order for the fundamental law of gearing to be true,the gear tooth contours on mating teeth must be conjugates of one another.There is an infinite number of possible conjugate pairs that could be used,but only a few curves have seen practical application as gear teeth.The cycloid still is used as a tooth form in watches and clocks.but most other gears use the involute curve for their shape. Involute curve The Involute Tooth Form The involute is a curve which can be generated by unwrapping a taut string from a cylin- "String”" tangent to der(called the evolute)as shown in Figure 9-5.Note the following about this involute base circle curve: and normal to involute The string is always tangent to the cylinder. The center of curvature of the involute is always at the point of tangency of the string with the cylinder. A tangent to the involute is then always normal to the string,the length of which is the instantaneous radius of curvature of the involute curve. Figure 9-6 shows two involutes on separate cylinders in contact or"in mesh."These represent gear teeth.The cylinders from which the strings are unwrapped are called the base cireles of the respective gears.Note that the base circles are necessarily smaller than the pitch circles,which are at the radii of the original rolling cylinders,rp and rg.The gear tooth must project both below and above the rolling cylinder surface(pitch circle) and the involute only exists outside of the base circle.The amount of tooth that sticks Base circle or evolute out above the pitch circle is the addendum,shown as ap and ag for pinion and gear,re- spectively.These are equal for standard,full-depth gear teeth. FIGURE 9-5 The geometry at this tooth-tooth interface is similar to that of a cam-follower Development of the joint as was defined in Figure 8-40(p.399).There is a common tangent to both involute of a circle

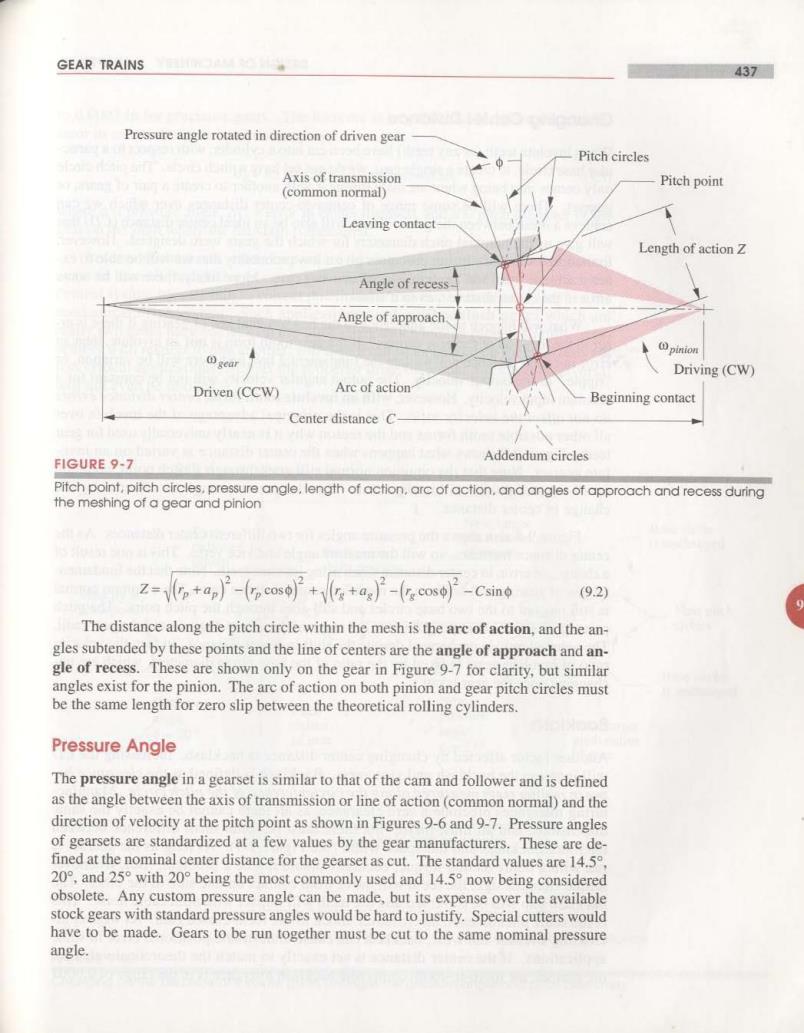

436 DESIGN OF MACHINERY CHAPTER 9 Pressure angle rotated in direction of driven gear Velocity at pitch point Axis of transmission or line of action Addendum of pinion ap (common normal)is tangent to both base circles Pitch radius of pinion rp Common tangent geur Pitch radius of gear re Pitch point pinion Driven(CCW) Driving(CW) Base circle of pinion Base circle of gear Pitch circles FIGURE 9-6 Addendum of gear ag Contact geometry and pressure angle of involute gear teeth curves at the contact point,and a common normal,perpendicular to the common tangent.Note that the common normal is,in fact,the "strings"of both involutes, which are colinear.Thus the common normal,which is also the axis of transmis- sion,always passes through the pitch point regardless of where in the mesh the two teeth are contacting. Figure 9-7 shows a pair of involute tooth forms in two positions,just beginning contact and about to leave contact.The common normals of both these contact points still pass through the same pitch point.It is this property of the involute that causes it to obey the fundamental law of gearing.The ratio of the driving gear radius to the driven gear radius remains constant as the teeth move into and out of mesh. From this observation of the behavior of the involute we can restate the funda- mental law of gearing in a more kinematically formal way as:the common normal of the tooth profiles,at all contact points within the mesh,must always pass through a fixed point on the line of centers,called the pitch point.The gearset's velocity ratio will then be a constant defined by the ratio of the respective radii of the gears to the pitch point. The points of beginning and leaving contact define the mesh of the pinion and gear. The distance along the line of action between these points within the mesh is called the length of action,Z,defined by the intersections of the respective addendum circles with the line of action,as shown in Figure 9-7

GEAR TRAINS 437 Pressure angle rotated in direction of driven gear Pitch circles Axis of transmission Pitch point (common normal) Leaving contact Length of action Z Angle of recess Angle of approach. gear pinion Driving(CW) Driven(CCW) Arc of action Beginning contact Center distance C- FIGURE 9-7 Addendum circles Pitch point,pitch circles,pressure angle,length of action.arc of action.and angles of approach and recess during the meshing of a gear and pinion z-p+ap)-(c)++a)-(cos)-csino (92) The distance along the pitch circle within the mesh is the are of action,and the an- gles subtended by these points and the line of centers are the angle of approach and an- gle of recess.These are shown only on the gear in Figure 9-7 for clarity,but similar angles exist for the pinion.The arc of action on both pinion and gear pitch circles must be the same length for zero slip between the theoretical rolling cylinders. Pressure Angle The pressure angle in a gearset is similar to that of the cam and follower and is defined as the angle between the axis of transmission or line of action(common normal)and the direction of velocity at the pitch point as shown in Figures 9-6 and 9-7.Pressure angles of gearsets are standardized at a few values by the gear manufacturers.These are de- fined at the nominal center distance for the gearset as cut.The standard values are 14.5, 20°,and25°with20°being the most commonly used and 14.5°now being considered obsolete.Any custom pressure angle can be made,but its expense over the available stock gears with standard pressure angles would be hard to justify.Special cutters would have to be made.Gears to be run together must be cut to the same nominal pressure angle

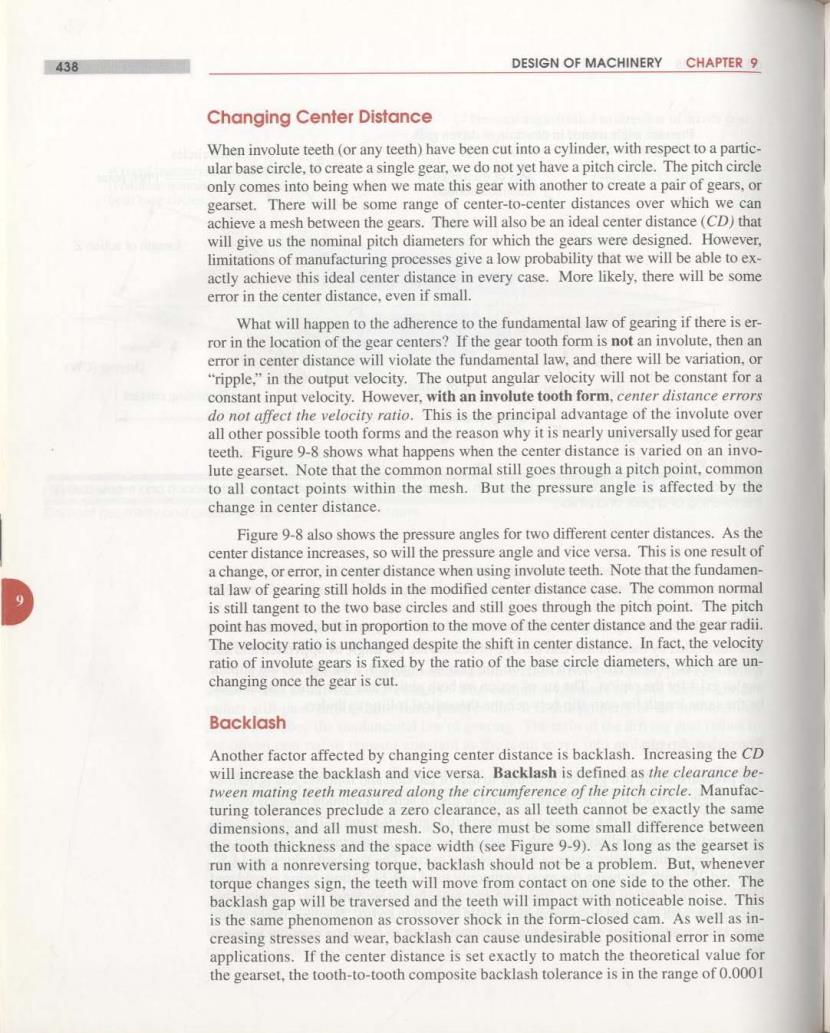

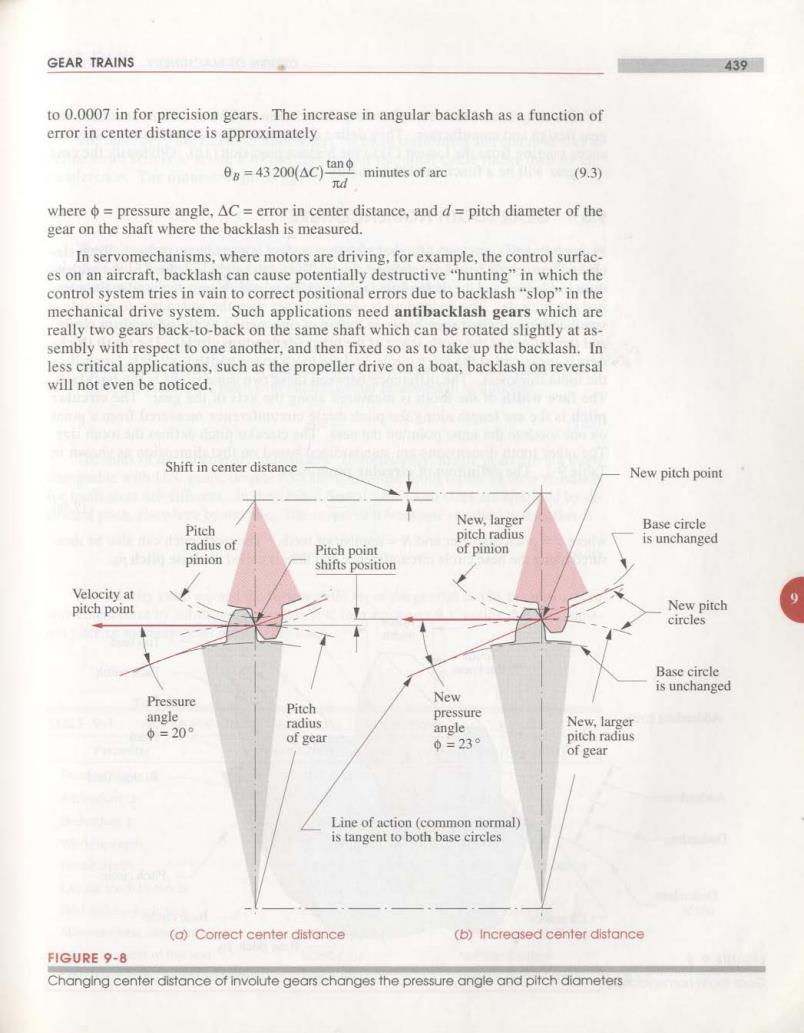

438 DESIGN OF MACHINERY CHAPTER 9 Changing Center Distance When involute teeth(or any teeth)have been cut into a cylinder,with respect to a partic- ular base circle,to create a single gear,we do not yet have a pitch circle.The pitch circle only comes into being when we mate this gear with another to create a pair of gears,or gearset.There will be some range of center-to-center distances over which we can achieve a mesh between the gears.There will also be an ideal center distance(CD)that will give us the nominal pitch diameters for which the gears were designed.However, limitations of manufacturing processes give a low probability that we will be able to ex- actly achieve this ideal center distance in every case.More likely,there will be some error in the center distance,even if small. What will happen to the adherence to the fundamental law of gearing if there is er- ror in the location of the gear centers?If the gear tooth form is not an involute,then an error in center distance will violate the fundamental law,and there will be variation,or "ripple,"in the output velocity.The output angular velocity will not be constant for a constant input velocity.However,with an involute tooth form,center distance errors do not affect the velocity ratio.This is the principal advantage of the involute over all other possible tooth forms and the reason why it is nearly universally used for gear teeth.Figure 9-8 shows what happens when the center distance is varied on an invo- lute gearset.Note that the common normal still goes through a pitch point,common to all contact points within the mesh.But the pressure angle is affected by the change in center distance. Figure 9-8 also shows the pressure angles for two different center distances.As the center distance increases,so will the pressure angle and vice versa.This is one result of a change,or error,in center distance when using involute teeth.Note that the fundamen- tal law of gearing still holds in the modified center distance case.The common normal is still tangent to the two base circles and still goes through the pitch point.The pitch point has moved,but in proportion to the move of the center distance and the gear radii The velocity ratio is unchanged despite the shift in center distance.In fact,the velocity ratio of involute gears is fixed by the ratio of the base circle diameters,which are un- changing once the gear is cut. Backlash Another factor affected by changing center distance is backlash.Increasing the CD will increase the backlash and vice versa.Backlash is defined as the clearance be- tween mating teeth measured along the circumference of the pitch circle.Manufac- turing tolerances preclude a zero clearance,as all teeth cannot be exactly the same dimensions,and all must mesh.So,there must be some small difference between the tooth thickness and the space width(see Figure 9-9).As long as the gearset is run with a nonreversing torque,backlash should not be a problem.But,whenever torque changes sign,the teeth will move from contact on one side to the other.The backlash gap will be traversed and the teeth will impact with noticeable noise.This is the same phenomenon as crossover shock in the form-closed cam.As well as in- creasing stresses and wear,backlash can cause undesirable positional error in some applications.If the center distance is set exactly to match the theoretical value for the gearset,the tooth-to-tooth composite backlash tolerance is in the range of 0.0001

GEAR TRAINS 439 to 0.0007 in for precision gears.The increase in angular backlash as a function of error in center distance is approximately 6B=43200(4Can minutes of arc (9.3) where pressure angle,AC error in center distance,and d pitch diameter of the gear on the shaft where the backlash is measured. In servomechanisms,where motors are driving,for example,the control surfac- es on an aircraft,backlash can cause potentially destructive "hunting"in which the control system tries in vain to correct positional errors due to backlash"slop"in the mechanical drive system.Such applications need antibacklash gears which are really two gears back-to-back on the same shaft which can be rotated slightly at as- sembly with respect to one another,and then fixed so as to take up the backlash.In less critical applications,such as the propeller drive on a boat,backlash on reversal will not even be noticed. Shift in center distance New pitch point Pitch New,larger Base circle pitch radius radius of is unchanged pinion Pitch point of pinion shifts position Velocity at New pitch 9 pitch point circles Base circle is unchanged Pressure New angle Pitch pressure radius angle New,larger 0=20° of gear 0=23° pitch radius of gear Line of action (common normal) is tangent to both base circles (o)Correct center distance (b)Increased center distance FIGURE 9-8 Changing center distance of involute gears changes the pressure angle and pitch diameters

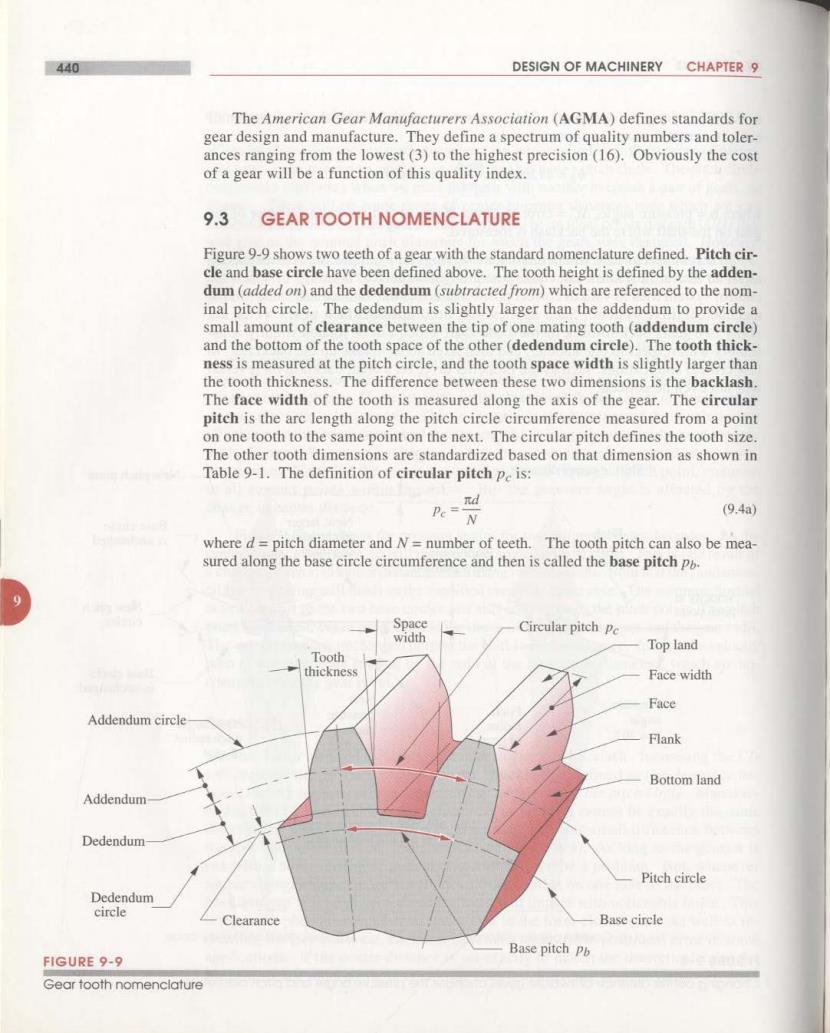

440 DESIGN OF MACHINERY CHAPTER 9 The American Gear Manufacturers Association (AGMA)defines standards for gear design and manufacture.They define a spectrum of quality numbers and toler- ances ranging from the lowest(3)to the highest precision (16).Obviously the cost of a gear will be a function of this quality index. 9.3 GEAR TOOTH NOMENCLATURE Figure 9-9 shows two teeth of a gear with the standard nomenclature defined.Pitch cir- cle and base circle have been defined above.The tooth height is defined by the adden- dum (added on)and the dedendum (subtracted from)which are referenced to the nom- inal pitch circle.The dedendum is slightly larger than the addendum to provide a small amount of clearance between the tip of one mating tooth(addendum circle) and the bottom of the tooth space of the other(dedendum circle).The tooth thick- ness is measured at the pitch circle,and the tooth space width is slightly larger than the tooth thickness.The difference between these two dimensions is the backlash. The face width of the tooth is measured along the axis of the gear.The circular pitch is the arc length along the pitch circle circumference measured from a point on one tooth to the same point on the next.The circular pitch defines the tooth size. The other tooth dimensions are standardized based on that dimension as shown in Table 9-1.The definition of circular pitch pe is: 么s N (9.4a) where d=pitch diameter and N=number of teeth.The tooth pitch can also be mea- sured along the base circle circumference and then is called the base pitch po. Space Circular pitch Pe width Top land Tooth thickness Face width Face Addendum circle Flank Bottom land Addendum Dedendum Pitch circle Dedendum circle Clearance Base circle Base pitch ph FIGURE 9-9 Gear tooth nomenclature

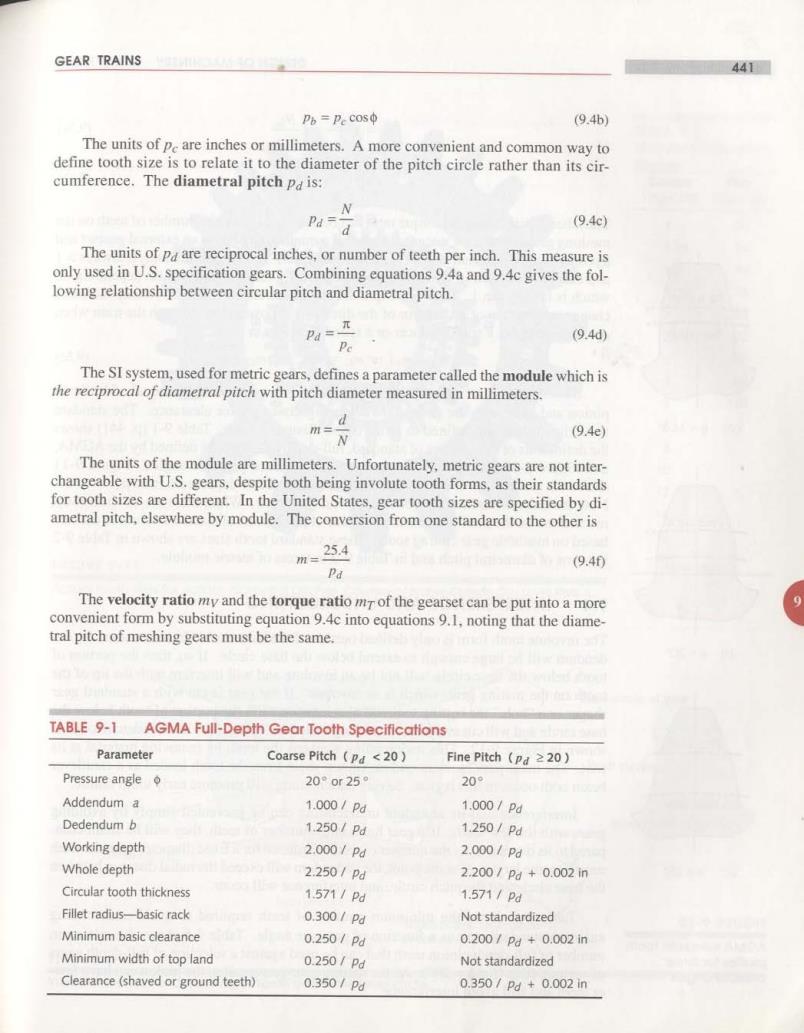

GEAR TRAINS 441 Pb=pe cosφ (9.4b) The units of pe are inches or millimeters.A more convenient and common way to define tooth size is to relate it to the diameter of the pitch circle rather than its cir- cumference.The diametral pitch Pd is: N Pd= d (9.4c) The units of pd are reciprocal inches,or number of teeth per inch.This measure is only used in U.S.specification gears.Combining equations 9.4a and 9.4c gives the fol- lowing relationship between circular pitch and diametral pitch. Pa=n (9.4d) Pe The SI system,used for metric gears,defines a parameter called the module which is the reciprocal of diametral pitch with pitch diameter measured in millimeters. N (9.4e) The units of the module are millimeters.Unfortunately,metric gears are not inter- changeable with U.S.gears,despite both being involute tooth forms,as their standards for tooth sizes are different.In the United States,gear tooth sizes are specified by di- ametral pitch,elsewhere by module.The conversion from one standard to the other is m=254 (9.40 Pa The velocity ratio my and the torque ratio mT of the gearset can be put into a more convenient form by substituting equation 9.4c into equations 9.1,noting that the diame- tral pitch of meshing gears must be the same. TABLE 9-1 AGMA Full-Depth Gear Tooth Specifications Parameter Coarse Pitch (pd <20) Fine Pitch (pd 220) Pressure angle 20°0r25° 20° Addendum a 1.000/Pd 1.000/pd Dedendum b 1.250/Pd 1.250/Pd Working depth 2.000/Pd 2.0o0/Pd Whole depth 2.2501pd 2.200/pd+0.002in Circular tooth thickness 1571/Pd 1.571/Pd Fillet radius-basic rack 0.3001Pd Not standardized Minimum basic clearance 0.250/Pd 0200/Pd+0.002in Minimum width of top land 0.250/Pd Not standardized Clearance(shaved or ground teeth) 0.350/Pd 0.350/pd+0.002n