Machine Tools Continued Manufacturing&Systems

Manufacturing& Systems Machine Tools Continued

Traditional metal cutting operations Turning (车削) >Facing (车端面) > Boring (镗削) > Drilling (钻削) Milling > (铣削) Broaching (拉削)

Traditional metal cutting operations Turning (车削) Facing (车端面) Boring (镗削) Drilling (钻削) Milling (铣削) Broaching (拉削)

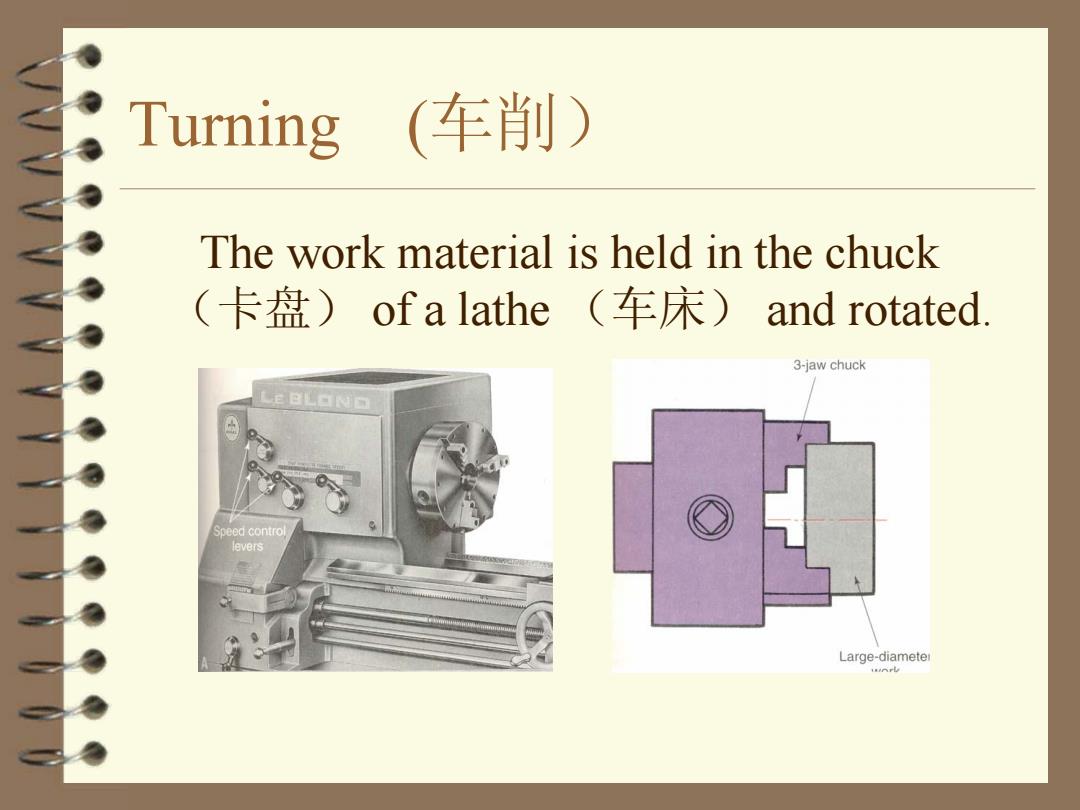

Turning (车削) The work material is held in the chuck (卡盘)of a lathe(车床)and rotated 3-jaw chuck EEL口m Speed control levers Large-diameter wnrl

Turning (车削) The work material is held in the chuck (卡盘) of a lathe (车床) and rotated

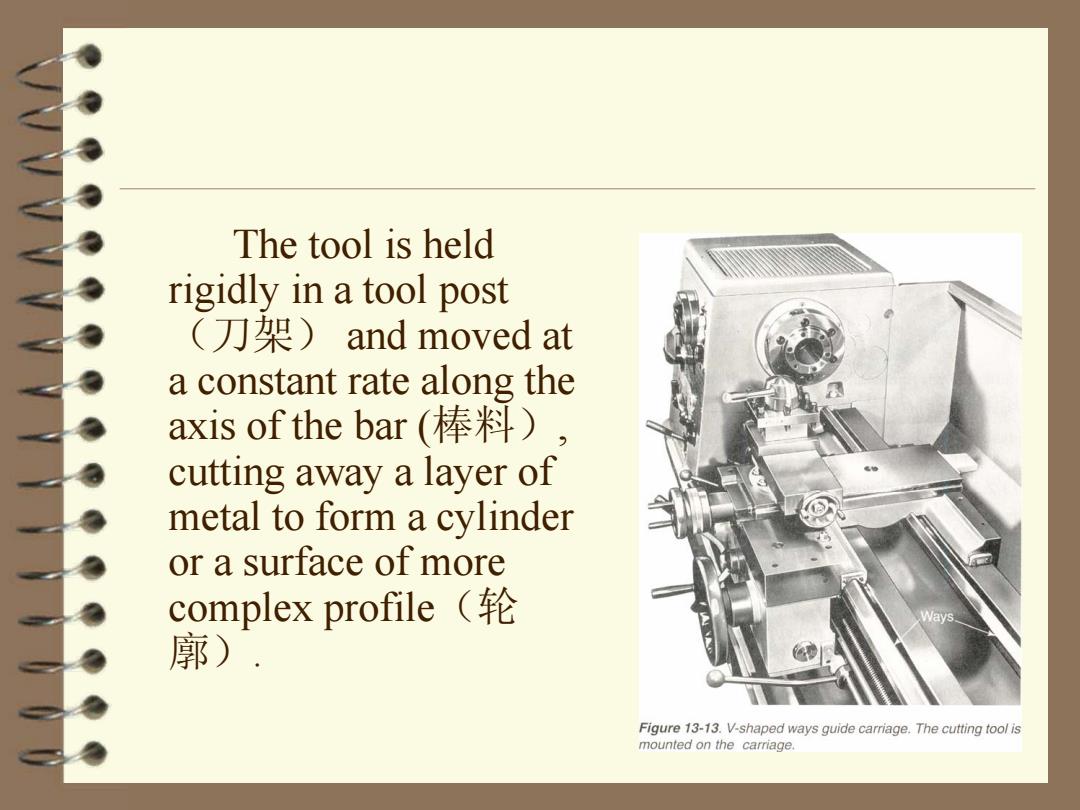

The tool is held rigidly in a tool post (刀架)and moved at a constant rate along the axis of the bar(棒料) cutting away a layer of metal to form a cylinder or a surface of more complex profile(轮 廓). Figure 13-13.V-shaped ways guide carriage.The cutting tool is mounted on the carriage

The tool is held rigidly in a tool post (刀架) and moved at a constant rate along the axis of the bar (棒料), cutting away a layer of metal to form a cylinder or a surface of more complex profile(轮 廓)

The cutting speed (V)is the rate at which the uncut surface of the work passes the cutting edge of the tool-usually expressed in units of m/min. The feed (f)is the distance moved by the tool in an axial direction at each revolution of the work

The cutting speed (V) is the rate at which the uncut surface of the work passes the cutting edge of the tool-usually expressed in units of m/min. The feed (f) is the distance moved by the tool in an axial direction at each revolution of the work

The depth of cut (w)is the thickness of metal removed from the bar,measured in a radial direction. The product of these three gives the rate of metal removal,a parameter often used in measuring the efficiency of a cutting operation. V fw=rate of metal removal

The depth of cut (w) is the thickness of metal removed from the bar, measured in a radial direction. The product of these three gives the rate of metal removal, a parameter often used in measuring the efficiency of a cutting operation. V f w = rate of metal removal

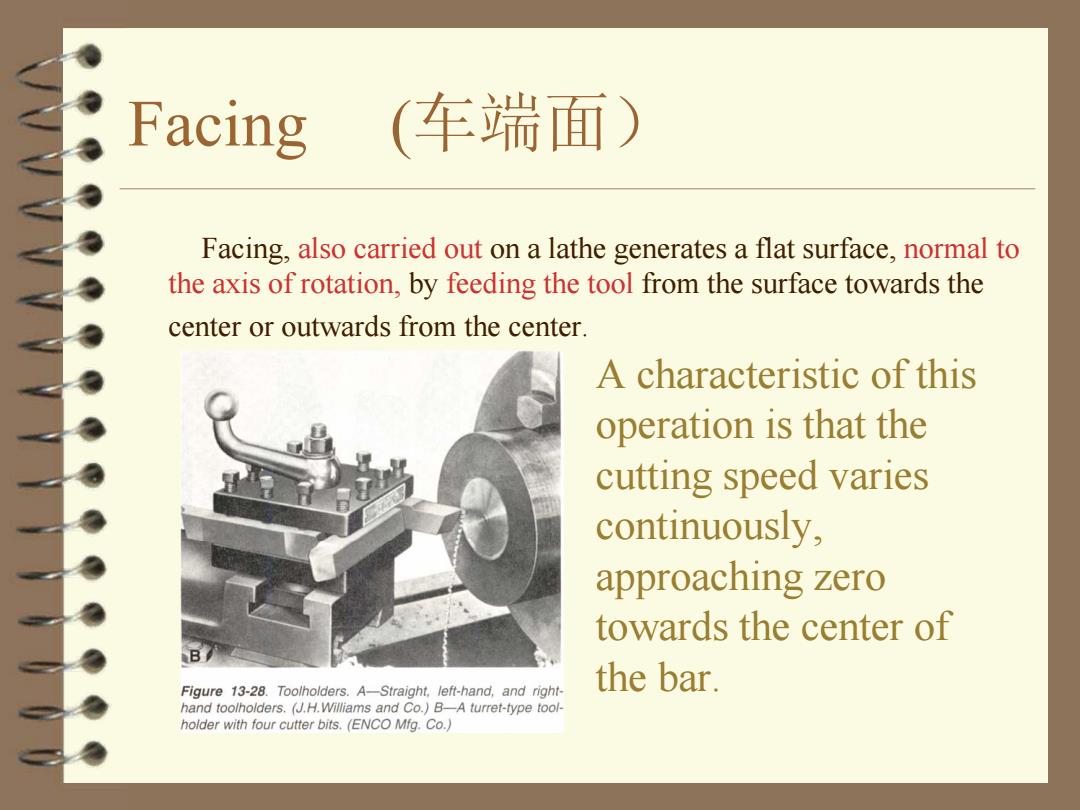

Facing (车端面) Facing,also carried out on a lathe generates a flat surface,normal to the axis of rotation,by feeding the tool from the surface towards the center or outwards from the center. A characteristic of this operation is that the cutting speed varies continuously, approaching zero towards the center of Figure 13-28.Toolholders.A-Straight,left-hand,and right- the bar hand toolholders.(J.H.Williams and Co.)B-A turret-type tool- holder with four cutter bits.(ENCO Mfg.Co.)

Facing (车端面) Facing, also carried out on a lathe generates a flat surface, normal to the axis of rotation, by feeding the tool from the surface towards the center or outwards from the center. A characteristic of this operation is that the cutting speed varies continuously, approaching zero towards the center of the bar

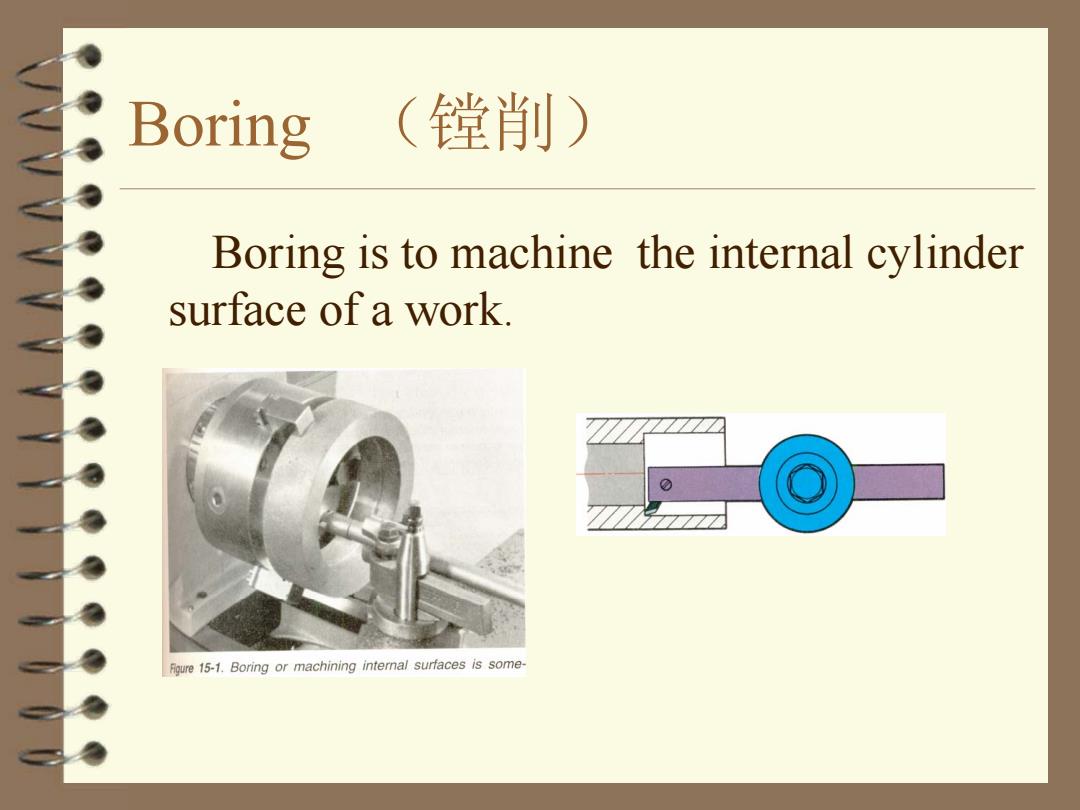

Boring (镗削) Boring is to machine the internal cylinder surface of a work. Figure 15-1.Boring or machining internal surfaces is some-

Boring (镗削) Boring is to machine the internal cylinder surface of a work

Essentially the conditions of boring differ little from those of turning,but this operation illustrates the importance of rigidity in machining

Essentially the conditions of boring differ little from those of turning, but this operation illustrates the importance of rigidity in machining

Particularly when a long cylinder with a small internal diameter is bored,the bar holding the tool must be long and slender and cannot be as rigid as the thick, stocky(短而粗的)tools and tool post used for most turning

Particularly when a long cylinder with a small internal diameter is bored, the bar ( 刀 杆) holding the tool must be long and slender and cannot be as rigid as the thick, stocky(短而粗的) tools and tool post used for most turning