Introduction to Engineering School of Mechanical Engineering Shanghai Jiao Tong University

Introduction to Engineering School of Mechanical Engineering Shanghai Jiao Tong University

Manufacturing Topic I Metal Cutting

Manufacturing Topic 1 Metal Cutting

Contents >2.1 Brief review over metal cutting history >2.2 Metal Cutting Related Industries

Contents 2.1 Brief review over metal cutting history 2.2 Metal Cutting Related Industries

2.1 Brief Review Over Metal Cutting History >The first cutting tool used by mankind: Broken bone Splintered flint(带锐角燧石) The search to find better tool materials and more efficient cutting methods started ever since

2.1 Brief Review Over Metal Cutting History The first cutting tool used by mankind: • Broken bone • Splintered flint(带锐角燧石). The search to find better tool materials and more efficient cutting methods started ever since

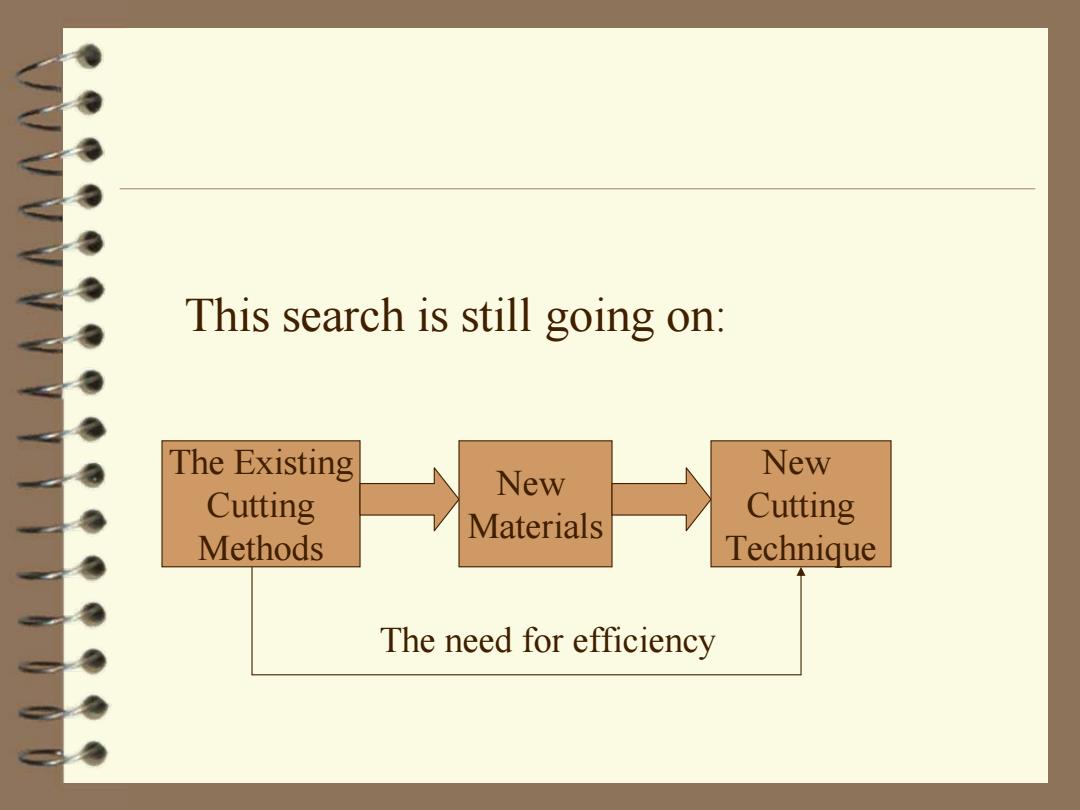

This search is still going on: The Existing New New Cutting Materials Cutting Methods Technique The need for efficiency

This search is still going on: The Existing Cutting Methods New Materials New Cutting Technique The need for efficiency

Before the middle of the 18th century WOOD:the main material used in engineering structure LATHES:the machine tools mainly used to cut these material Exceptions:boring of cannon,production of metal screws and small instrument parts

Before the middle of the 18th century WOOD: the main material used in engineering structure LATHES: the machine tools mainly used to cut these material Exceptions: boring of cannon, production of metal screws and small instrument parts

>In the middle of 18th century The Steam The First Major Engine Developments In Metal Cutting Why? Because the steam engine needs: Large metal cylinders and other parts Very high dimensional accuracy

Why? Because the steam engine needs: Large metal cylinders and other parts Very high dimensional accuracy The Steam Engine The First Major Developments In Metal Cutting In the middle of 18th century

The materials for the first steam engines were gray cast iron(灰铸铁) wrought iron(熟铁) brass_ (黄铜) bronze(青铜)

The materials for the first steam engines were gray cast iron ( 灰铸铁) wrought iron (熟铁) brass (黄铜) bronze (青铜)

Those materials were not difficult to machine using hardened carbon steel tools (cutter). Cutting speed should be kept very low to avoid rapid failure of the cutting tools. It required 27 and half working days to bore and face one of Watt's large cylinders[4]

Those materials were not difficult to machine using hardened carbon steel tools (cutter). Cutting speed should be kept very low to avoid rapid failure of the cutting tools. It required 27 and half working days to bore and face one of Watt’s large cylinders[4]

Between 1760 and 1860 Many machine tools enterprises appeared. Many great engineers devoted their lives to perfecting the machine tools required for generating many shapes in metallic components Cylindrical and flat surfaces *Threads *Grooves Slots and holes

Between 1760 and 1860 Many machine tools enterprises appeared. Many great engineers devoted their lives to perfecting the machine tools required for generating many shapes in metallic components. Cylindrical and flat surfaces Threads Grooves Slots and holes