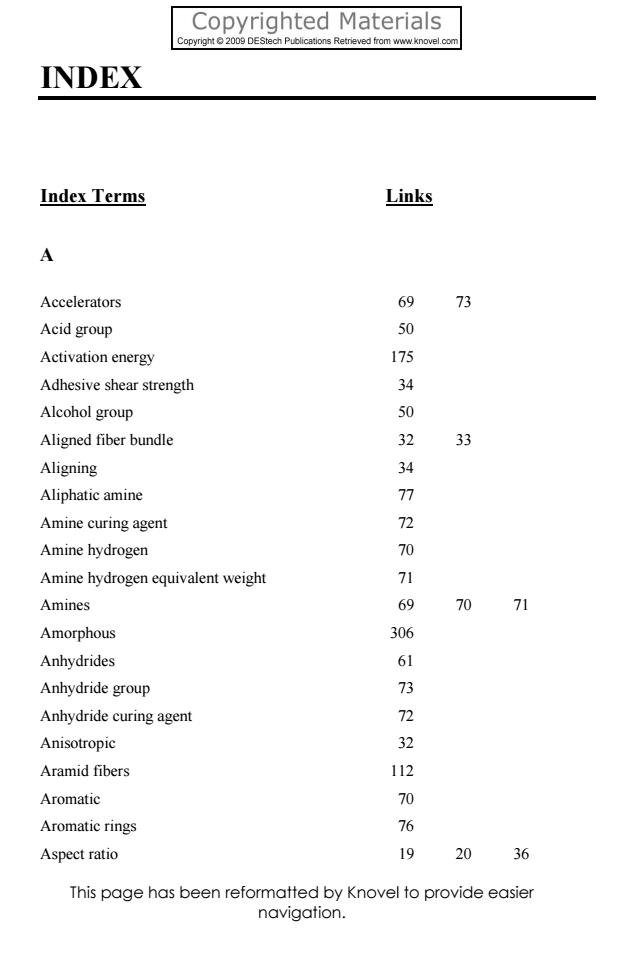

Copyrighted Materials Copyright2009 DEStech Publications Retrieved from www.knovel.com INDEX Index Terms Links A Accelerators 69 73 Acid group 50 Activation energy 175 Adhesive shear strength 34 Alcohol group 50 Aligned fiber bundle 32 33 Aligning 34 Aliphatic amine 77 Amine curing agent 72 Amine hydrogen 70 Amine hydrogen equivalent weight 71 Amines 69 70 71 Amorphous 306 Anhydrides 61 Anhydride group 73 Anhydride curing agent 72 Anisotropic 32 Aramid fibers 112 Aromatic 70 Aromatic rings 76 Aspect ratio 19 20 36 This page has been reformatted by Knovel to provide easier navigation

This page has been reformatted by Knovel to provide easier navigation. INDEX Index Terms Links A Accelerators 69 73 Acid group 50 Activation energy 175 Adhesive shear strength 34 Alcohol group 50 Aligned fiber bundle 32 33 Aligning 34 Aliphatic amine 77 Amine curing agent 72 Amine hydrogen 70 Amine hydrogen equivalent weight 71 Amines 69 70 71 Amorphous 306 Anhydrides 61 Anhydride group 73 Anhydride curing agent 72 Anisotropic 32 Aramid fibers 112 Aromatic 70 Aromatic rings 76 Aspect ratio 19 20 36

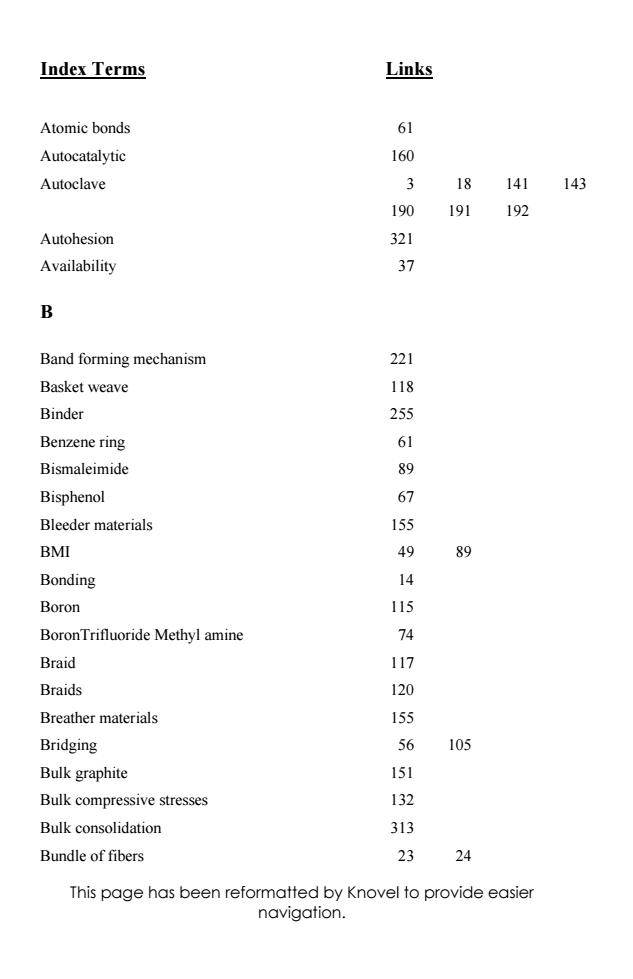

Index Terms Links Atomic bonds 61 Autocatalytic 160 Autoclave 3 18 141 143 190 191 192 Autohesion 321 Availability 37 B Band forming mechanism 221 Basket weave 118 Binder 255 Benzene ring 61 Bismaleimide 89 Bisphenol 67 Bleeder materials 155 BMI 49 89 Bonding 14 Boron 115 BoronTrifluoride Methyl amine 74 Braid 117 Braids 120 Breather materials 155 Bridging 56 105 Bulk graphite 151 Bulk compressive stresses 132 Bulk consolidation 313 Bundle of fibers 23 24 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Atomic bonds 61 Autocatalytic 160 Autoclave 3 18 141 143 190 191 192 Autohesion 321 Availability 37 B Band forming mechanism 221 Basket weave 118 Binder 255 Benzene ring 61 Bismaleimide 89 Bisphenol 67 Bleeder materials 155 BMI 49 89 Bonding 14 Boron 115 BoronTrifluoride Methyl amine 74 Braid 117 Braids 120 Breather materials 155 Bridging 56 105 Bulk graphite 151 Bulk compressive stresses 132 Bulk consolidation 313 Bundle of fibers 23 24

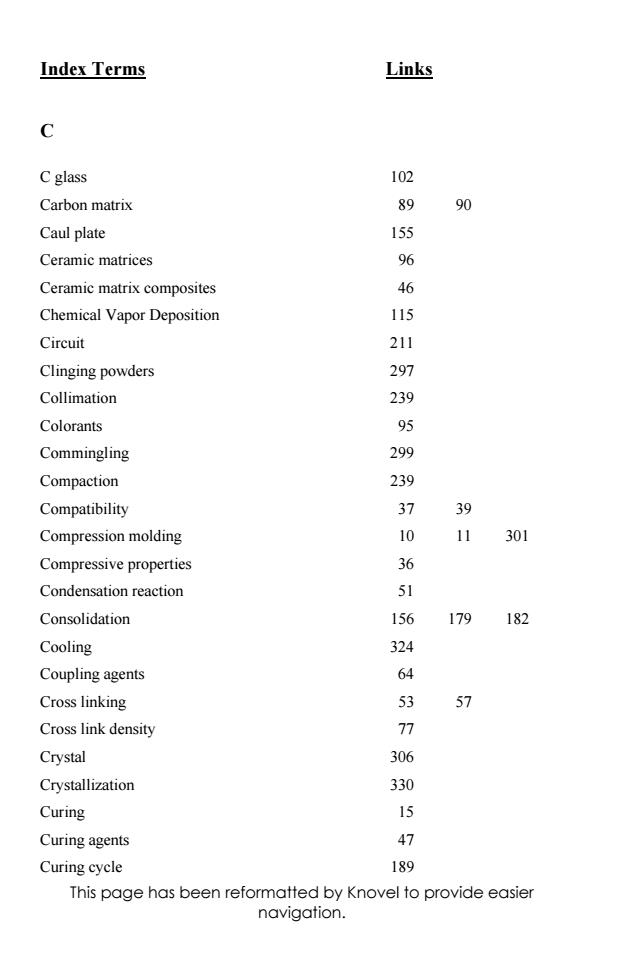

Index Terms Links C Cglass 102 Carbon matrix 89 90 Caul plate 155 Ceramic matrices 96 Ceramic matrix composites 46 Chemical Vapor Deposition 115 Circuit 211 Clinging powders 297 Collimation 239 Colorants 95 Commingling 299 Compaction 239 Compatibility 37 39 Compression molding 10 11 301 Compressive properties 36 Condensation reaction 51 Consolidation 156 179 182 Cooling 324 Coupling agents 64 Cross linking 53 57 Cross link density 77 Crystal 306 Crystallization 330 Curing 15 Curing agents 47 Curing cycle 189 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. C C glass 102 Carbon matrix 89 90 Caul plate 155 Ceramic matrices 96 Ceramic matrix composites 46 Chemical Vapor Deposition 115 Circuit 211 Clinging powders 297 Collimation 239 Colorants 95 Commingling 299 Compaction 239 Compatibility 37 39 Compression molding 10 11 301 Compressive properties 36 Condensation reaction 51 Consolidation 156 179 182 Cooling 324 Coupling agents 64 Cross linking 53 57 Cross link density 77 Crystal 306 Crystallization 330 Curing 15 Curing agents 47 Curing cycle 189

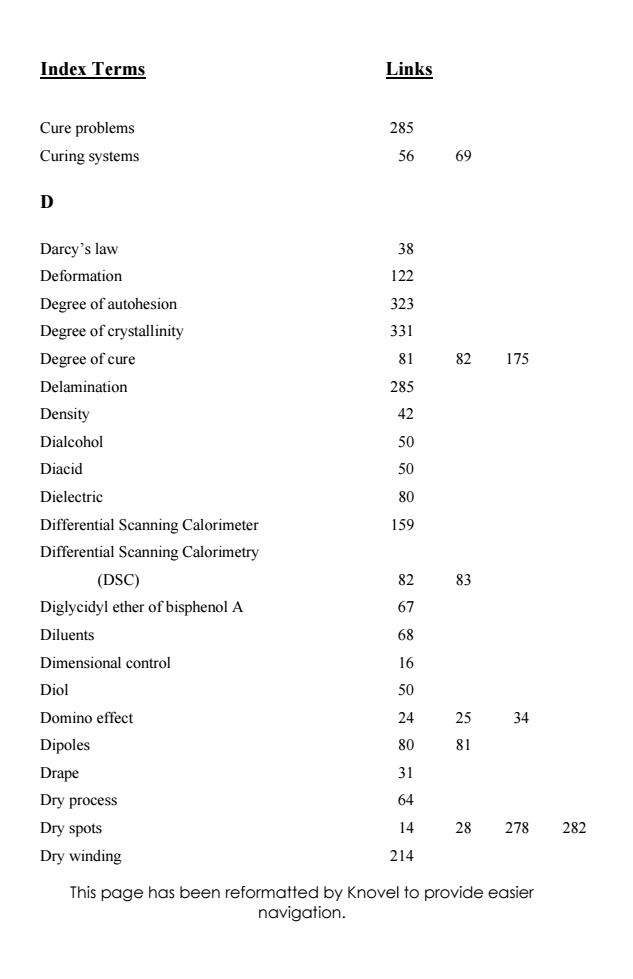

Index Terms Links Cure problems 285 Curing systems 56 69 D Darcy's law 38 Deformation 122 Degree of autohesion 323 Degree of crystallinity 331 Degree of cure 81 82 175 Delamination 285 Density 42 Dialcohol 50 Diacid 50 Dielectric 80 Differential Scanning Calorimeter 159 Differential Scanning Calorimetry (DSC) 82 83 Diglycidyl ether of bisphenol A 67 Diluents 68 Dimensional control 16 Diol 50 Domino effect 24 25 34 Dipoles 80 81 Drape 31 Dry process 64 Dry spots 14 28 278 282 Dry winding 214 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Cure problems 285 Curing systems 56 69 D Darcy’s law 38 Deformation 122 Degree of autohesion 323 Degree of crystallinity 331 Degree of cure 81 82 175 Delamination 285 Density 42 Dialcohol 50 Diacid 50 Dielectric 80 Differential Scanning Calorimeter 159 Differential Scanning Calorimetry (DSC) 82 83 Diglycidyl ether of bisphenol A 67 Diluents 68 Dimensional control 16 Diol 50 Domino effect 24 25 34 Dipoles 80 81 Drape 31 Dry process 64 Dry spots 14 28 278 282 Dry winding 214

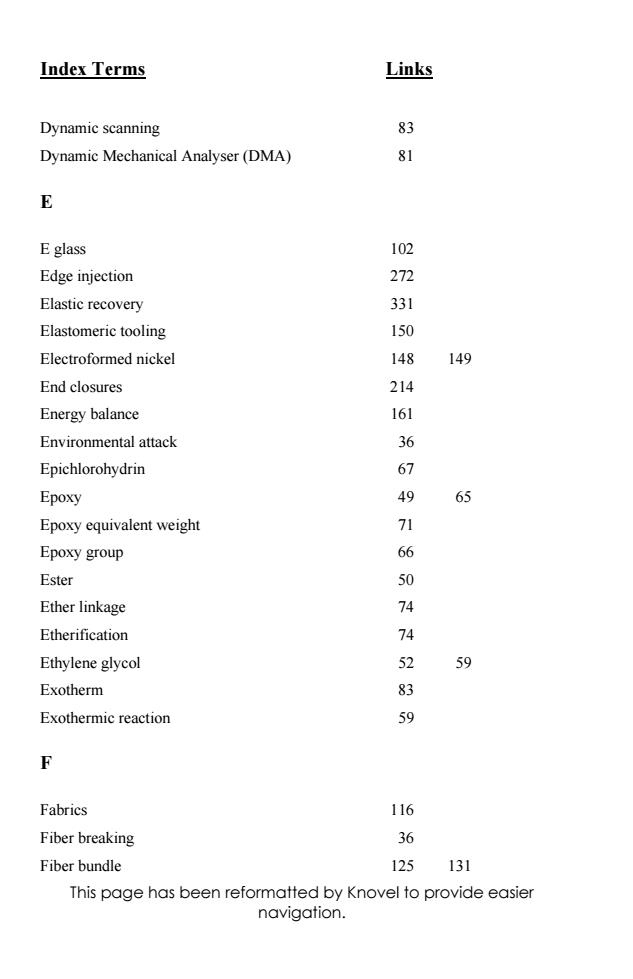

Index Terms Links Dynamic scanning 83 Dynamic Mechanical Analyser(DMA) 81 E E glass 102 Edge injection 272 Elastic recovery 331 Elastomeric tooling 150 Electroformed nickel 148 149 End closures 214 Energy balance 161 Environmental attack 36 Epichlorohydrin 67 Epoxy 49 65 Epoxy equivalent weight 71 Epoxy group 66 Ester 50 Ether linkage 74 Etherification 74 Ethylene glycol 52 59 Exotherm 83 Exothermic reaction 59 F Fabrics 116 Fiber breaking 36 Fiber bundle 125 131 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Dynamic scanning 83 Dynamic Mechanical Analyser (DMA) 81 E E glass 102 Edge injection 272 Elastic recovery 331 Elastomeric tooling 150 Electroformed nickel 148 149 End closures 214 Energy balance 161 Environmental attack 36 Epichlorohydrin 67 Epoxy 49 65 Epoxy equivalent weight 71 Epoxy group 66 Ester 50 Ether linkage 74 Etherification 74 Ethylene glycol 52 59 Exotherm 83 Exothermic reaction 59 F Fabrics 116 Fiber breaking 36 Fiber bundle 125 131

Index Terms Links Fiber motion 225 Fiber placement 11 12 13 205 230 334 Fiber to fiber contact 30 Fiber washing 275 278 Fiberglass 101 Fibers 99 Filament 116 Filament winding 5 6 13 18 205 Fill 118 Fillers 95 Filling time 274 282 Finish 102 Flame resistance 96 Flow enhancement fabrics 255 Forming 124 G Gel coat 142 Geodesic path 215 Glass fibers 100 Graphite fibers 106 H Hand laminating 141 142 Hand-lay-up 3 4 13 18 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Fiber motion 225 Fiber placement 11 12 13 205 230 334 Fiber to fiber contact 30 Fiber washing 275 278 Fiberglass 101 Fibers 99 Filament 116 Filament winding 5 6 13 18 205 Fill 118 Fillers 95 Filling time 274 282 Finish 102 Flame resistance 96 Flow enhancement fabrics 255 Forming 124 G Gel coat 142 Geodesic path 215 Glass fibers 100 Graphite fibers 106 H Hand laminating 141 142 Hand-lay-up 3 4 13 18

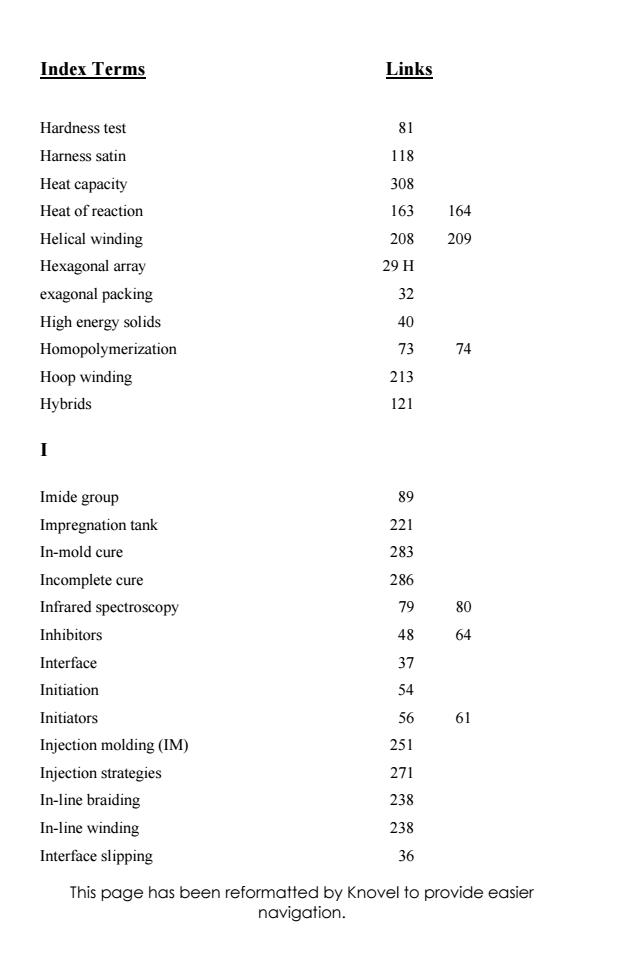

Index Terms Links Hardness test 81 Harness satin 118 Heat capacity 308 Heat of reaction 163 164 Helical winding 208 209 Hexagonal array 29H exagonal packing 32 High energy solids 40 Homopolymerization 73 74 Hoop winding 213 Hybrids 121 I Imide group 89 Impregnation tank 221 In-mold cure 283 Incomplete cure 286 Infrared spectroscopy 79 80 Inhibitors 48 64 Interface 37 Initiation 54 Initiators 56 61 Injection molding(IM) 251 Injection strategies 271 In-line braiding 238 In-line winding 238 Interface slipping 36 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Hardness test 81 Harness satin 118 Heat capacity 308 Heat of reaction 163 164 Helical winding 208 209 Hexagonal array 29 H exagonal packing 32 High energy solids 40 Homopolymerization 73 74 Hoop winding 213 Hybrids 121 I Imide group 89 Impregnation tank 221 In-mold cure 283 Incomplete cure 286 Infrared spectroscopy 79 80 Inhibitors 48 64 Interface 37 Initiation 54 Initiators 56 61 Injection molding (IM) 251 Injection strategies 271 In-line braiding 238 In-line winding 238 Interface slipping 36

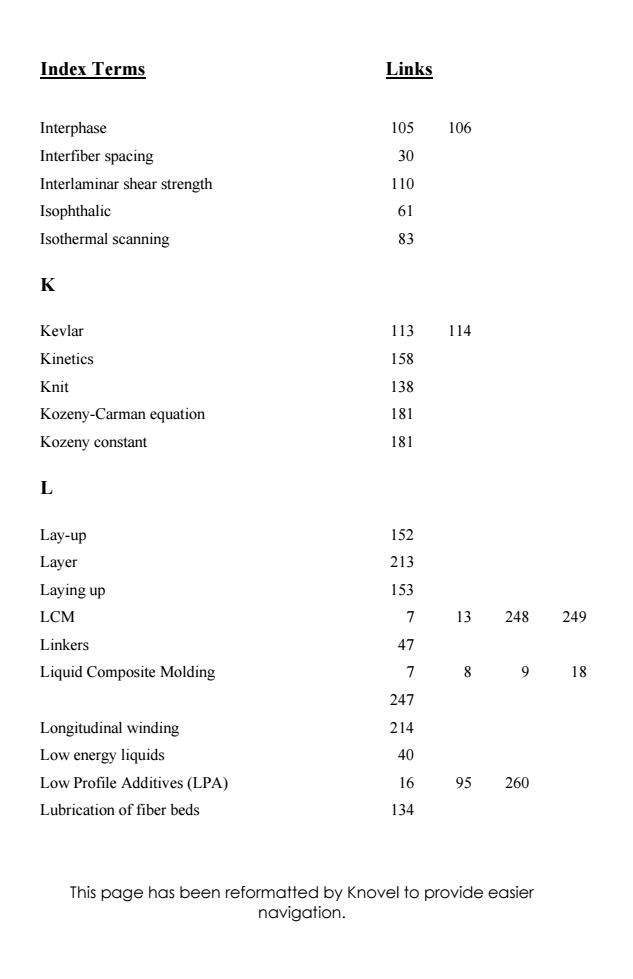

Index Terms Links Interphase 105 106 Interfiber spacing 30 Interlaminar shear strength 110 Isophthalic 61 Isothermal scanning 83 K Kevlar 113 114 Kinetics 158 Knit 138 Kozeny-Carman equation 181 Kozeny constant 181 L Lay-up 152 Layer 213 Laying up 153 LCM 7 13 248 249 Linkers 47 Liquid Composite Molding 7 8 9 18 247 Longitudinal winding 214 Low energy liquids 40 Low Profile Additives(LPA) 16 95 260 Lubrication of fiber beds 134 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Interphase 105 106 Interfiber spacing 30 Interlaminar shear strength 110 Isophthalic 61 Isothermal scanning 83 K Kevlar 113 114 Kinetics 158 Knit 138 Kozeny-Carman equation 181 Kozeny constant 181 L Lay-up 152 Layer 213 Laying up 153 LCM 7 13 248 249 Linkers 47 Liquid Composite Molding 7 8 9 18 247 Longitudinal winding 214 Low energy liquids 40 Low Profile Additives (LPA) 16 95 260 Lubrication of fiber beds 134

Index Terms Links M Maleic acid 52 59 Mandrels 216 217 218 219 Mat 117 Material handling 219 Mats 119 Matrix 34 45 Metal matrix 96 Metal matrix composites 40 Methyl Ethyl Ketone Peroxide(MEKP) 54 56 87 Microbraiding 299 300 Modifiers 95 Mold filling 262 Molding 124 Modulus development 193 N nth order 160 Netting analysis 220 222 Non woven broadgoods 235 0 Open mold 65 Organic fibers 112 Organic peroxides 54 Orthophthalic 61 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. M Maleic acid 52 59 Mandrels 216 217 218 219 Mat 117 Material handling 219 Mats 119 Matrix 34 45 Metal matrix 96 Metal matrix composites 40 Methyl Ethyl Ketone Peroxide (MEKP) 54 56 87 Microbraiding 299 300 Modifiers 95 Mold filling 262 Molding 124 Modulus development 193 N nth order 160 Netting analysis 220 222 Non woven broadgoods 235 O Open mold 65 Organic fibers 112 Organic peroxides 54 Orthophthalic 61

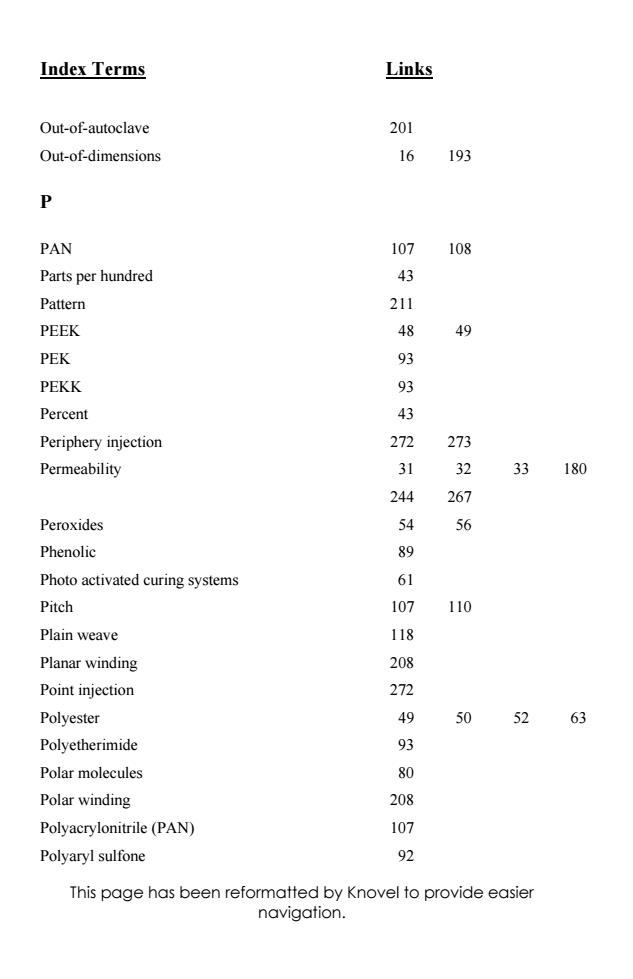

Index Terms Links Out-of-autoclave 201 Out-of-dimensions 16 193 P PAN 107 108 Parts per hundred 43 Pattern 211 PEEK 48 49 PEK 93 PEKK 93 Percent 43 Periphery injection 272 273 Permeability 31 32 33 180 244 267 Peroxides 54 56 Phenolic 89 Photo activated curing systems 61 Pitch 107 110 Plain weave 118 Planar winding 208 Point injection 272 Polyester 49 50 52 63 Polyetherimide 93 Polar molecules 80 Polar winding 208 Polyacrylonitrile(PAN) 107 Polyaryl sulfone 92 This page has been reformatted by Knovel to provide easier navigation

Index Terms Links This page has been reformatted by Knovel to provide easier navigation. Out-of-autoclave 201 Out-of-dimensions 16 193 P PAN 107 108 Parts per hundred 43 Pattern 211 PEEK 48 49 PEK 93 PEKK 93 Percent 43 Periphery injection 272 273 Permeability 31 32 33 180 244 267 Peroxides 54 56 Phenolic 89 Photo activated curing systems 61 Pitch 107 110 Plain weave 118 Planar winding 208 Point injection 272 Polyester 49 50 52 63 Polyetherimide 93 Polar molecules 80 Polar winding 208 Polyacrylonitrile (PAN) 107 Polyaryl sulfone 92