第二相颗粒 弥散 析出 Dispersion Precipitation 不可溶 基体中相变形成 。非共格 ·共格/非共格 例如铜中氧化铝颗 例如Al-Cu合金中 粒 的析出相

第二相颗粒 弥散 Dispersion • 不可溶 • 非共格 • 例如铜中氧化铝颗 粒 析出 Precipitation • 基体中相变形成 • 共格/非共格 • 例如Al-Cu合金中 的析出相

第二相颗粒结构 完全共格 存在应变的共格 (a) (b) 半共格 非共格 (c) (d)

完全共格 存在应变的共格 半共格 非共格 第二相颗粒结构

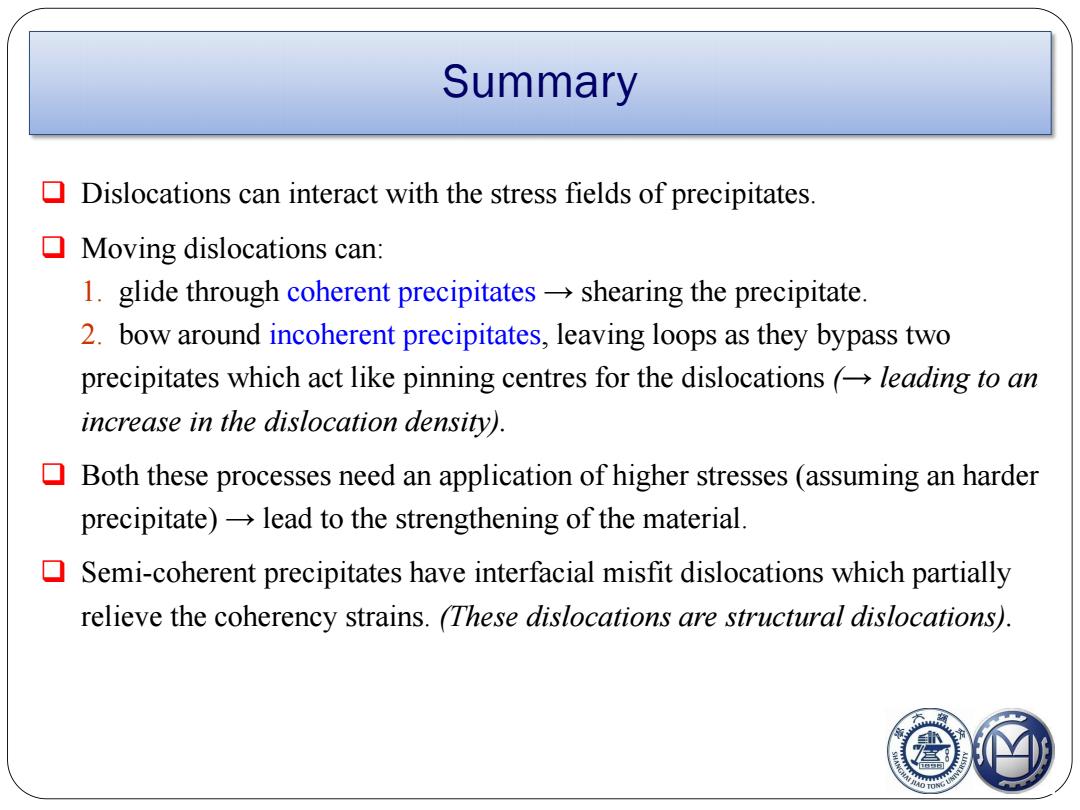

Summary Dislocations can interact with the stress fields of precipitates. Moving dislocations can: 1.glide through coherent precipitates->shearing the precipitate. 2.bow around incoherent precipitates,leaving loops as they bypass two precipitates which act like pinning centres for the dislocations leading to an increase in the dislocation density). Both these processes need an application of higher stresses (assuming an harder precipitate)lead to the strengthening of the material. ▣ Semi-coherent precipitates have interfacial misfit dislocations which partially relieve the coherency strains.(These dislocations are structural dislocations). 轨

Summary 4 q Dislocations can interact with the stress fields of precipitates. q Moving dislocations can: 1. glide through coherent precipitates → shearing the precipitate. 2. bow around incoherent precipitates, leaving loops as they bypass two precipitates which act like pinning centres for the dislocations (→ leading to an increase in the dislocation density). q Both these processes need an application of higher stresses (assuming an harder precipitate) → lead to the strengthening of the material. q Semi-coherent precipitates have interfacial misfit dislocations which partially relieve the coherency strains. (These dislocations are structural dislocations)

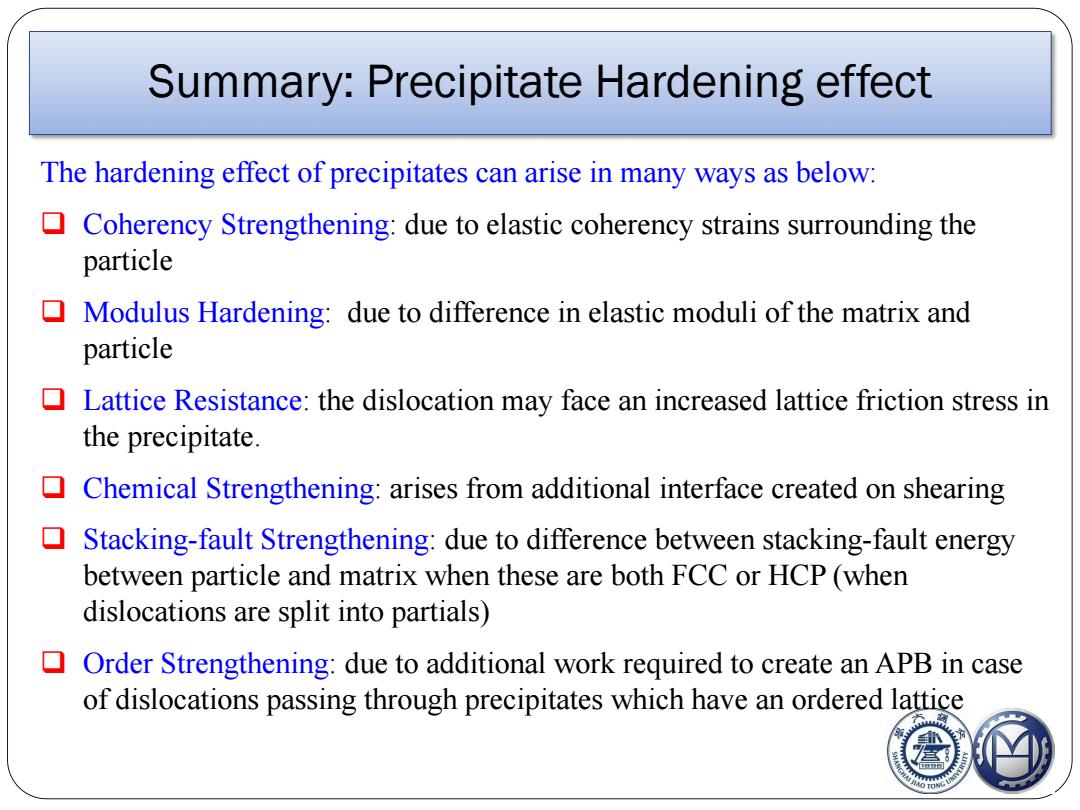

Summary:Precipitate Hardening effect The hardening effect of precipitates can arise in many ways as below: Coherency Strengthening:due to elastic coherency strains surrounding the particle Modulus Hardening:due to difference in elastic moduli of the matrix and particle Lattice Resistance:the dislocation may face an increased lattice friction stress in the precipitate. Chemical Strengthening:arises from additional interface created on shearing Stacking-fault Strengthening:due to difference between stacking-fault energy between particle and matrix when these are both FCC or HCP(when dislocations are split into partials) Order Strengthening:due to additional work required to create an APB in case of dislocations passing through precipitates which have an ordered lattice

Summary: Precipitate Hardening effect 5 The hardening effect of precipitates can arise in many ways as below: q Coherency Strengthening: due to elastic coherency strains surrounding the particle q Modulus Hardening: due to difference in elastic moduli of the matrix and particle q Lattice Resistance: the dislocation may face an increased lattice friction stress in the precipitate. q Chemical Strengthening: arises from additional interface created on shearing q Stacking-fault Strengthening: due to difference between stacking-fault energy between particle and matrix when these are both FCC or HCP (when dislocations are split into partials) q Order Strengthening: due to additional work required to create an APB in case of dislocations passing through precipitates which have an ordered lattice

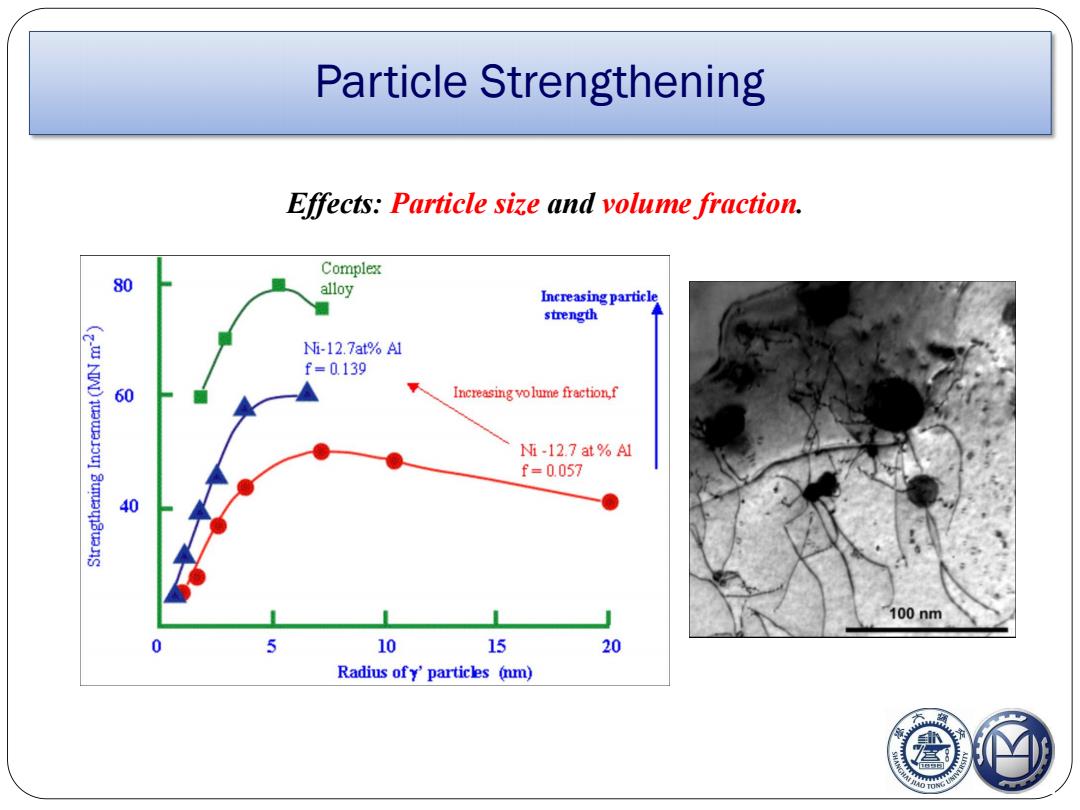

Particle Strengthening Effects:Particle size and volume fraction Complex 80 alloy Increasing particle strength Ni-12.7at%Al f=0139 60 Increasing volume fraction,f i-12.7at%A1 f=0.057 40 100nm 0 10 15 20 Radius ofy'particles (nm)

Particle Strengthening Ef ects: Particle size and volume fraction

经典第二相形貌 ●W-Y2O3 ·Cu-Al2O3 ·Fe-NbC(VC,TiC) ·Ni-gamma ·Al-析出相 国

经典第二相形貌 W-Y2O3 Cu-Al2O3 Fe-NbC (VC,TiC) Ni-gamma ’ Al-析出相

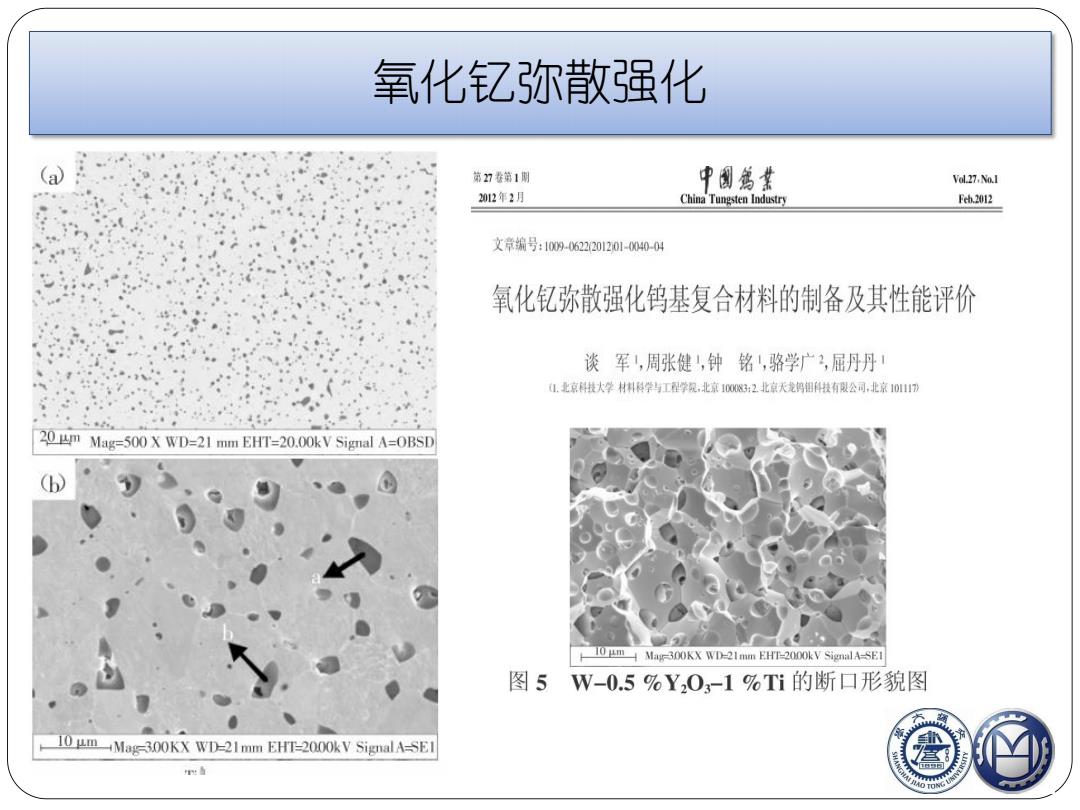

氧化钇你撒强化 第27卷第1期 中國篱菜 Vol.27.No.I 2012年2月 China Tungsten Industry Feh.2012 文章编号:1009-0622201201-0040-04 氧化钇弥散强化钨基复合材料的制备及其性能评价 谈军,周张健,钟铭,骆学广3,屈丹丹 山.北京科技大学材料科学马工学观,北京1003:2北京天是妈相科技有灵公司,北京10111》 20 m Mag=500 X WD=21 mm EHT=20.00kV Signal A=OBSD b T0 gm Mag300KX WD-21mm EHT-2000kV SignalA-SEI 图5W-0.5%Y,03-1%Ti的断口形貌图 10 umMag-300KX WD-21mm EHT-2000kV Signal A-SEI 世当

氧化钇弥散强化

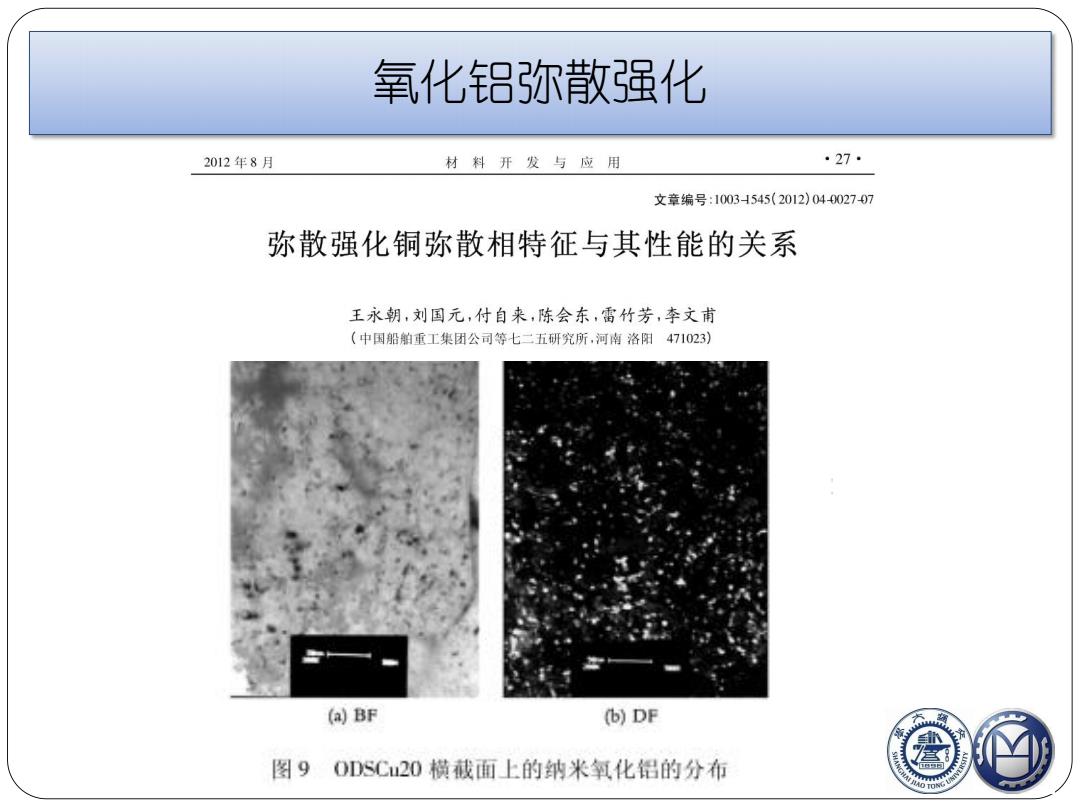

氧化铝你撒强化 2012年8月 材料开发与应用 ·27· 文章编号:1003H545(2012)04002707 弥散强化铜弥散相特征与其性能的关系 王永朝,刘国元,付自来,陈会东,雷竹芳,李文甫 (中国船舶重工集团公司等七二五研究所,河南洛阳471023) (a)BF (b)DF 图9ODSC20横截面上的纳米氧化铝的分布

氧化铝弥散强化

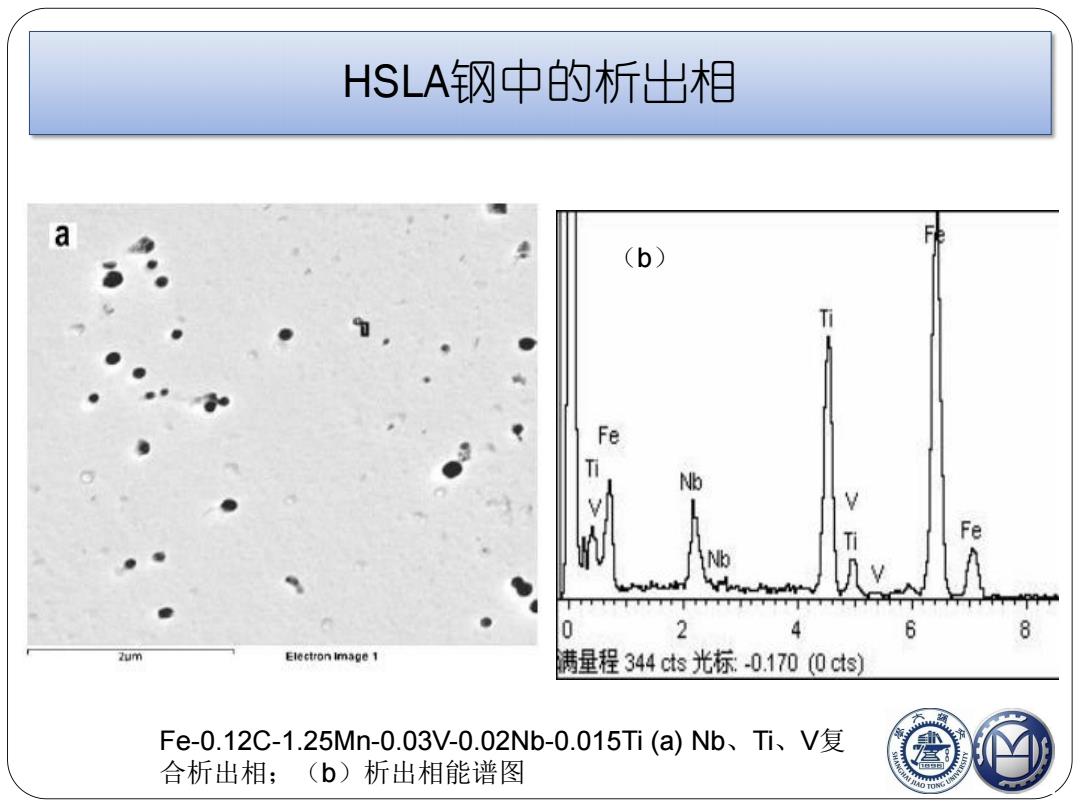

HSLA钢中的析出相 a (b) Ti Fe Ti Nb Ti Fe 0 2 4 6 8 Zum Electron Image 1 满量程344cts光标-0.170(0cts) Fe-0.12C-1.25Mn-0.03V-0.02Nb-0.015Ti(a))Nb、Ti、V复 合析出相; (b)析出相能谱图

HSLA钢中的析出相 Fe-0.12C-1.25Mn-0.03V-0.02Nb-0.015Ti (a) Nb、Ti、V复 合析出相;(b)析出相能谱图 (b)

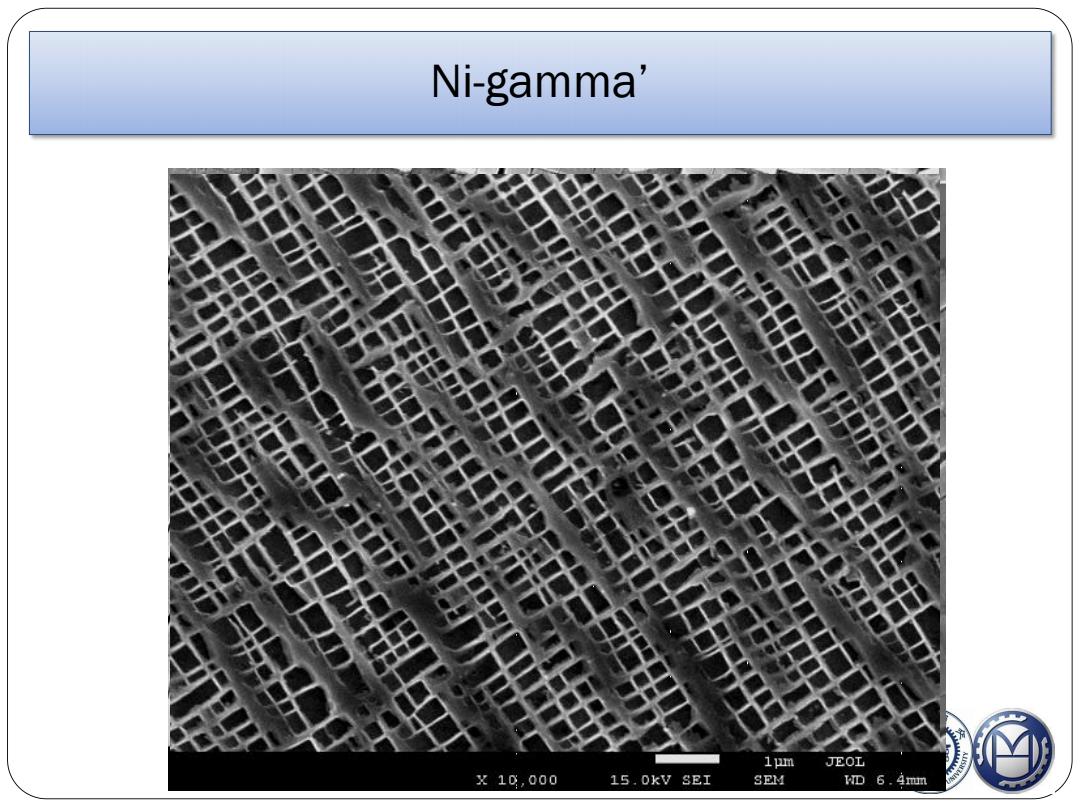

Ni-gamma 1pm JEOL X10:,000 15.0kV SEI SEM WD 6.4mm

Ni-gamma’