Chapter 10 Air Supply Devices and Pneumatic Com Similar to hydraulic transmission,pneumatic transmission performs the function of energy transfer and control by the medium of flow.They have a great deal in common in the aspects of working principle,components'structure,system composition and graphic symbol.The readers should notice their differences. A pneumatic system incorporates the following components and devices: (1)Air supply devices (2)Actuators (3)Control elements (4)Pneumatic attachments Homepage List Upwards Downwards Return Exit

Chapter 10 Air Supply Devices and Pneumatic Components 1 A pneumatic system incorporates the following components and devices: (1)Air supply devices (2) Actuators (3)Control elements (4)Pneumatic attachments Similar to hydraulic transmission, pneumatic transmission performs the function of energy transfer and control by the medium of flow. They have a great deal in common in the aspects of working principle, components’structure,system composition and graphic symbol. The readers should notice their differences

Chapler 1 Air Sppy Devees and Pneumatie Cp Chapter list 10.1 Air Supply Devices 10.2 Pneumatic Pneumatic Attachments 10.3 Pneumatic Actuators 10.4 Pneumatic Regulating Valves 2 Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 2 10.1 Air Supply Devices 10.2 Pneumatic Pneumatic Attachments 10.3 Pneumatic Actuators 10.4 Pneumatic Regulating Valves Chapter list

Chupter 1 Air Suppy Devies and Peumi C 10.1 Air Supply Devices 10.1.1 Pressure generation devices 10.1.2 Purification and storing devices and equipments compressed air 10.1.3 F.R.L Combination Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 3 10.1 Air Supply Devices 10.1.1 Pressure generation devices 10.1.2 Purification and storing devices and equipments compressed air 10.1.3 F.R.L Combination

Choper 1AirSp Dedees Pnm Conpn 10.1 Air Supply Devices Air supply devices are used to provide compressed air (with a certain lever of pressure,flow rate and purification)for pneumatic system. An air supply device incorporates four parts (1)pressure generation devices; (2)air regeneration; (③)storing devices; (4)air lines and F.R.L combination. Normally the first two parts are located in compressed air station as a center to supply gas in industry or workshop,see Fig.10-1. 4 Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 4 10.1 Air Supply Devices Air supply devices are used to provide compressed air (with a certain lever of pressure, flow rate and purification) for pneumatic system. An air supply device incorporates four parts: (1) pressure generation devices; (2) air regeneration; (3) storing devices; (4) air lines and F.R.L combination. Normally the first two parts are located in compressed air station as a center to supply gas in industry or workshop, see Fig. 10-1

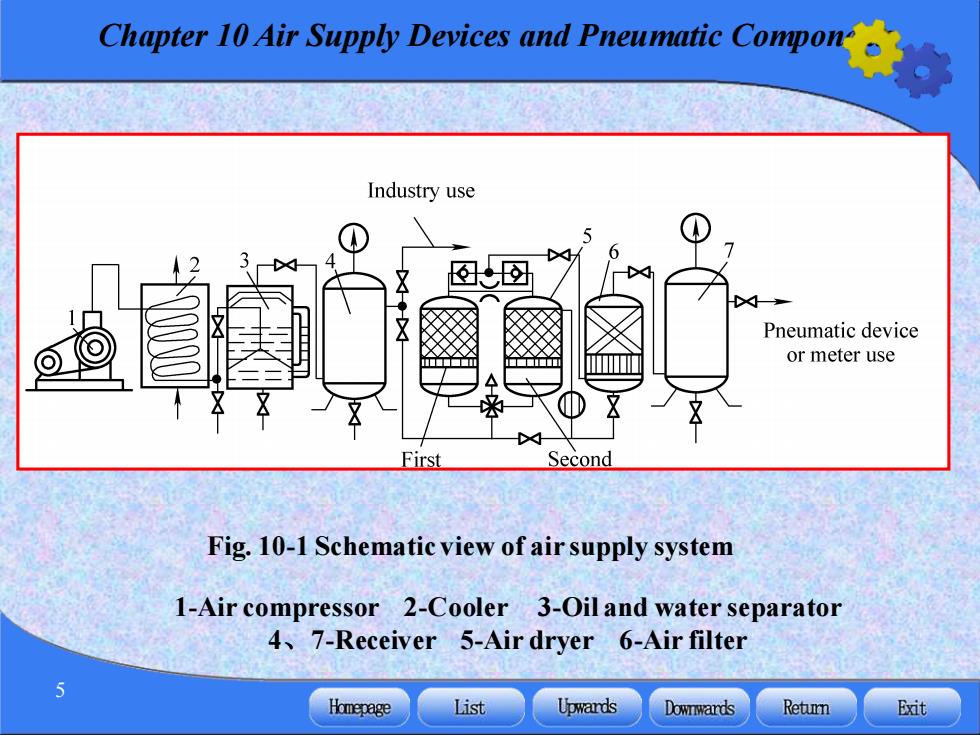

Chapter 10 Air Supply Devices and Pnemi C Industry use 囵囹 Pneumatic device or meter use First Second Fig.10-1 Schematic view of air supply system 1-Air compressor 2-Cooler 3-Oil and water separator 4,7-Receiver 5-Air dryer 6-Air filter Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 5 Fig. 10-1 Schematic view of air supply system 1-Air compressor 2-Cooler 3-Oil and water separator 4、7-Receiver 5-Air dryer 6-Air filter

hapter 10 Air Supply Devices and Pneumatic Compon 10.1.1 Pressure generation devices 1.Compressor classification According to working principles:displacement and dynamic; According to structures:see Fig.10-2; According to output pressures:low pressure (0.2~1.0MPa). medium pressure (1.0~10MPa),high pressure(10~100MPa), superhigh pressure (>100MPa). According to output flow rates(delivery):mini(<1m3/min),small (1~10 m3/min),medium (10~100 m3/min),large (100 m3/min). 6 Homepage List Upwards Downwards Retumn Exit

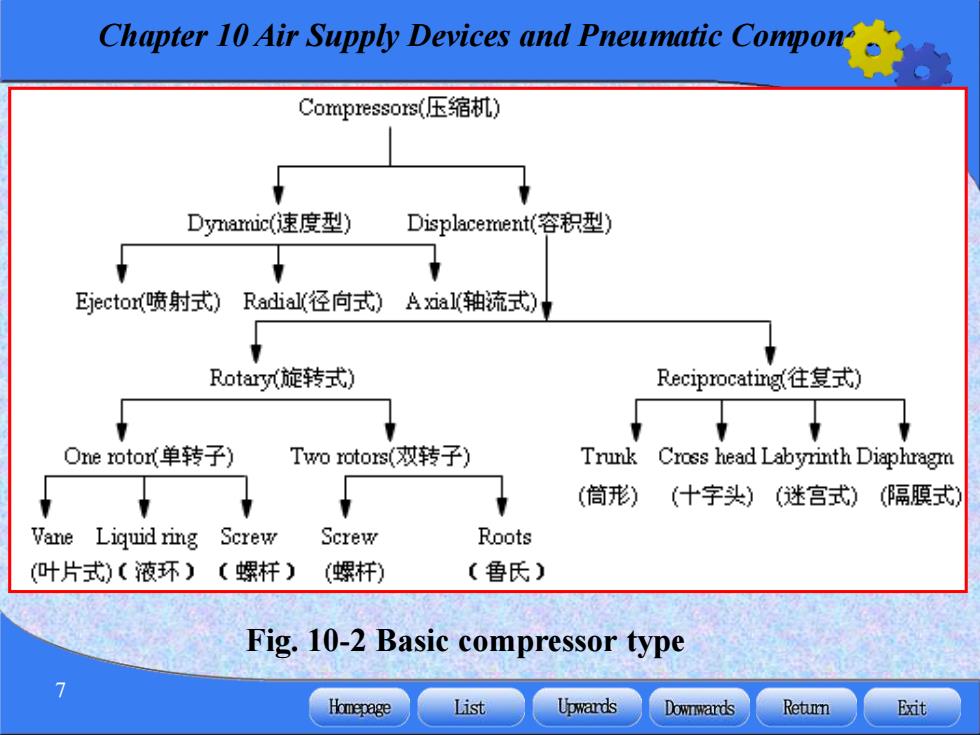

Chapter 10 Air Supply Devices and Pneumatic Components 6 10.1.1 Pressure generation devices 1. Compressor classification According to working principles: displacement and dynamic; According to structures: see Fig.10-2; According to output pressures: low pressure (0.2~1.0MPa), medium pressure (1.0~10MPa), high pressure (10~100MPa), superhigh pressure (>100MPa). According to output flow rates (delivery): mini (100 m3 /min)

Chapter 1 Air Supply Devices and Pneumatic Como Compressors(压缩机) Dynamic(速度型) Displacement(容积型) Ejecton(喷射式) Radial(径向式)Aial(轴流式) Rotary旋转式) Reciprocating(往复式) One rotor(单转子) Two rotors(双转子) Trunk Cross head Labyrinth Diaphragm (筒形) (十字头)(迷宫式)(隔源式) Vane Liquid ring Screw Screw Roots 叶片式)(液环)〔螺杆) (螺杆) (鲁氏) Fig.10-2 Basic compressor type Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 7 Fig. 10-2 Basic compressor type

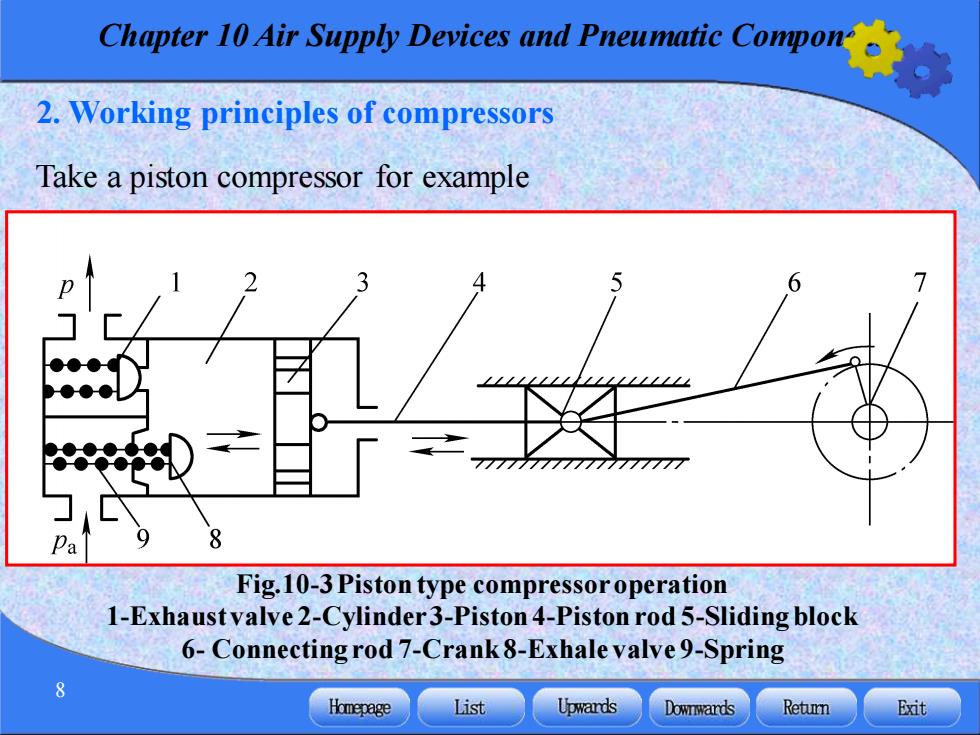

Chapter 10 Air Supply Devices and Pneumatic Compon 2.Working principles of compressors Take a piston compressor for example L 777777777777 Fig.10-3 Piston type compressoroperation 1-Exhaust valve 2-Cylinder 3-Piston 4-Piston rod 5-Sliding block 6-Connectingrod 7-Crank8-Exhale valve 9-Spring 8 Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 8 2. Working principles of compressors Take a piston compressor for example Fig.10-3 Piston type compressor operation 1-Exhaust valve 2-Cylinder 3-Piston 4-Piston rod 5-Sliding block 6- Connecting rod 7-Crank 8-Exhale valve 9-Spring

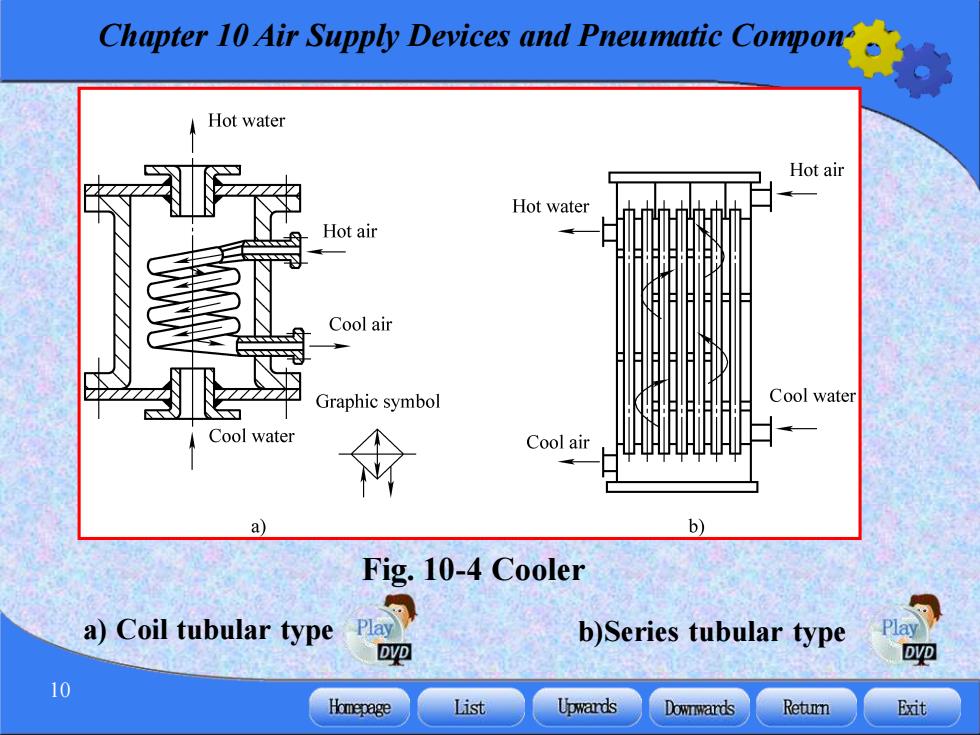

Chopter 1 Air Suppy Devices nd Pnem 10.1.2 Purification and storing devices and equipments compressed air 1. Demands for better quality of compressed air 2.Purification and storing equipments for compressed air (1)Cooler Coolers can be further classified based on their arrangement:coil tubular type(see Fig.10-4a),series tubular type(see Fig.10-4b), thermosyphon system and tube drive type.There are two types of cooling:water cooling and air cooling 9 Homepage List Upwards Dowrwards Retun Exit

Chapter 10 Air Supply Devices and Pneumatic Components 9 10.1.2 Purification and storing devices and equipments compressed air 1. Demands for better quality of compressed air 2. Purification and storing equipments for compressed air (1) Cooler Coolers can be further classified based on their arrangement: coil tubular type (see Fig. 10-4a), series tubular type (see Fig. 10-4b), thermosyphon system and tube drive type. There are two types of cooling: water cooling and air cooling

ter 10 Air Supply Devices and Pneumatic Com Hot water Hot air Hot water Hot air Cool air Graphic symbol Cool wate Cool water Cool air b) Fig.10-4 Cooler a)Coil tubular type Play b)Series tubular type Play DVD DVD 10 Homepage List Upwards Downwards Retumn Exit

Chapter 10 Air Supply Devices and Pneumatic Components 10 a) Coil tubular type b)Series tubular type Fig. 10-4 Cooler