Logistics Network Configuration Xiaohong Pang Automation Department Shanghai Jiaotong University

Logistics Network Configuration Xiaohong Pang Automation Department Shanghai Jiaotong University

Lecture Outline Introduction Data Collection -Solution Techniques

Lecture Outline Introduction Data Collection Solution Techniques

The Logistics Network What is it? The Logistics Network consists of: Facilities: Suppliers,Manufacturers,Warehouse, Distribution Centers,and Retail Outlets Raw materials,work-in-process inventory and finished products flow between the facilities

The Logistics Network What is it? The Logistics Network consists of: Facilities: Suppliers, Manufacturers, Warehouse, Distribution Centers, and Retail Outlets Raw materials, work-in-process inventory and finished products flow between the facilities

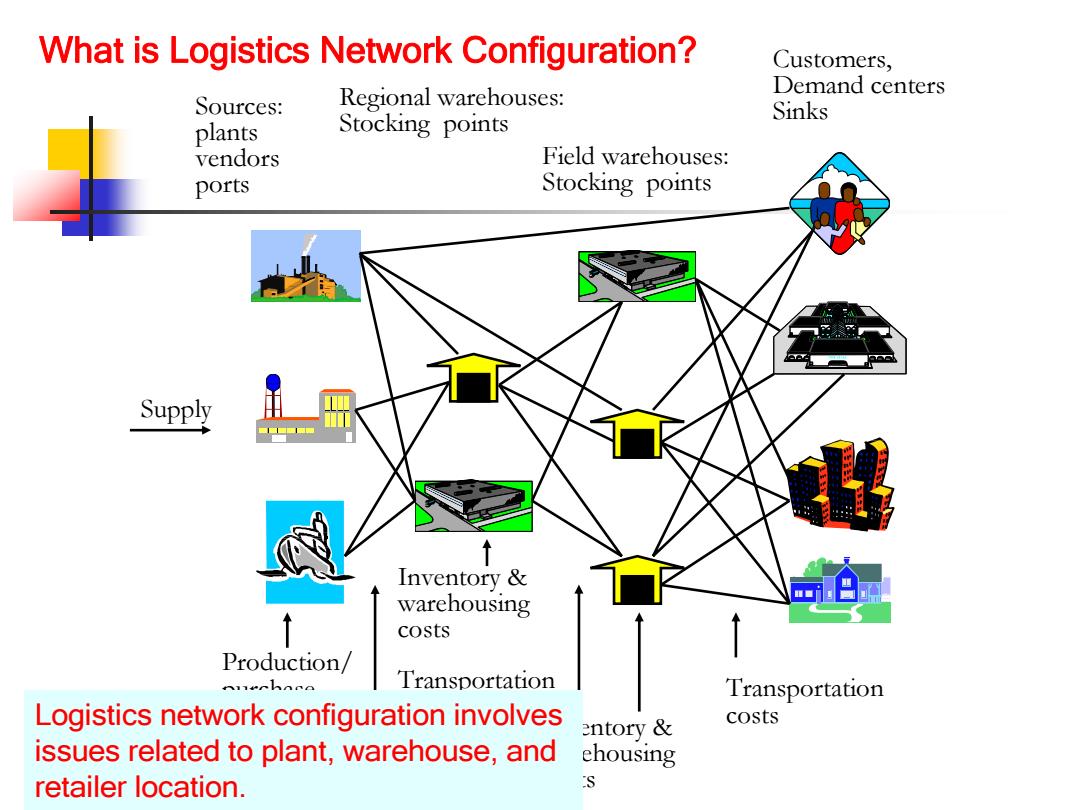

What is Logistics Network Configuration? Customers, Demand centers Sources: Regional warehouses: Sinks plants Stocking points vendors Field warehouses: ports Stocking points Supply Inventory warehousing costs Production/ Transportation Transportation Logistics network configuration involves entory costs issues related to plant,warehouse,and ehousing retailer location. S

Supply Sources: plants vendors ports Regional warehouses: Stocking points Field warehouses: Stocking points Customers, Demand centers Sinks Production/ purchase costs Inventory & warehousing costs Transportation costs Inventory & warehousing costs Transportation Logistics network configuration involves costs issues related to plant, warehouse, and retailer location. What is Logistics Network Configuration?

I Decision Classifications Strategic Planning: Decisions that typically involve major capital investments and have a long term effect Determination of the number,location and size of new plants,distribution centers and warehouses Acquisition of new production equipments and the design of working centers within each plant Design of transportation facilities,communication equipments,data processing means,etc

Decision Classifications Strategic Planning: Decisions that typically involve major capital investments and have a long term effect Determination of the number, location and size of new plants, distribution centers and warehouses Acquisition of new production equipments and the design of working centers within each plant Design of transportation facilities, communication equipments, data processing means, etc

Decision Classifications Tactical Planning: Effective allocation of manufacturing and distribution resources over a period of several months ■Work-force size ■Inventory policies Definition of the distribution channels Selection of transportation and trans-shipment alternatives

Decision Classifications Tactical Planning: Effective allocation of manufacturing and distribution resources over a period of several months Work-force size Inventory policies Definition of the distribution channels Selection of transportation and trans-shipment alternatives

Decision Classifications Operational Control: Includes day-to-day operational decisions The assignment of customer orders to individual machines -Dispatching,expediting and processing orders Vehicle scheduling

Decision Classifications Operational Control: Includes day-to-day operational decisions The assignment of customer orders to individual machines Dispatching, expediting and processing orders Vehicle scheduling

Network Design:Key Issues Pick the optimal number,location,and size of warehouses and/or plants Determine optimal sourcing strategy Which plant/vendor should produce which product Determine best distribution channels Which warehouses should serve which customers

Network Design: Key Issues Pick the optimal number, location, and size of warehouses and/or plants Determine optimal sourcing strategy Which plant/vendor should produce which product Determine best distribution channels Which warehouses should serve which customers

Network Design:Key Issues The objective is to balance service level against Production/purchasing costs Inventory carrying costs Facility costs (handling and fixed costs) Transportation costs That is,we have to find a minimal-annual-cost configuration of the distribution network that satisfies customer demands at specified service levels

Network Design: Key Issues The objective is to balance service level against Production/ purchasing costs Inventory carrying costs Facility costs (handling and fixed costs) Transportation costs That is, we have to find a minimal-annual-cost configuration of the distribution network that satisfies customer demands at specified service levels

Network Design Tools: Major Components Mapping Mapping allows you to visualize your supply chain and solutions Mapping the solutions allows you to better understand different scenarios Color coding,sizing,and utilization indicators allow for further analysis Data Data specifies the costs of your supply chain The baseline cost data should match your accounting data The output data allows you to quantify changes to the supply chain Engine Optimization Techniques

Network Design Tools: Major Components Mapping Mapping allows you to visualize your supply chain and solutions Mapping the solutions allows you to better understand different scenarios Color coding, sizing, and utilization indicators allow for further analysis Data Data specifies the costs of your supply chain The baseline cost data should match your accounting data The output data allows you to quantify changes to the supply chain Engine Optimization Techniques