UNIT TWO PACKAGING MATERIALS AND CONTAINER 第二单元 包装材料和容器

UNIT TWO PACKAGING MATERIALS AND CONTAINER 第二单元 包装材料和容器

Lesson 3 Paper and Paperboard 第3课 纸与纸板

Lesson 3 Paper and Paperboard 第3课 纸与纸板

Introduction Definition of paper: ·Paper is defined as a matted or felted sheet usually composed of plant fiber. Paper has been commercially made from such fiber sources as rags (linen), bagasse (sugar cane), cotton, and straw. Modern paper is made almost exclusively from cellulose fiber derived from wood. ·Although the word “paper” is derived from the Egyptian term, “papyrus” was not a true paper in the modern sense. - Invention of paper ·The invention of paper by blending cellulose fibers didn’t occur until the beginning of the second century A.D

Introduction Definition of paper: ·Paper is defined as a matted or felted sheet usually composed of plant fiber. Paper has been commercially made from such fiber sources as rags (linen), bagasse (sugar cane), cotton, and straw. Modern paper is made almost exclusively from cellulose fiber derived from wood. ·Although the word “paper” is derived from the Egyptian term, “papyrus” was not a true paper in the modern sense. - Invention of paper ·The invention of paper by blending cellulose fibers didn’t occur until the beginning of the second century A.D

Introduction Ts’ai Lun, a member of the court of the later Han Dynasty, is generally credited with developing the first real papermaking process in 105 A.D. ·The “Fourdrinier machine” was the first on the market and produced a homogenous (single-ply) sheet of boxboard in various thicknesses. It was soon joined by the “Cylinder machine” which formed a multi-layered (multi-ply) type of paperboard. These machines were first installed in the United States around 1830

Introduction Ts’ai Lun, a member of the court of the later Han Dynasty, is generally credited with developing the first real papermaking process in 105 A.D. ·The “Fourdrinier machine” was the first on the market and produced a homogenous (single-ply) sheet of boxboard in various thicknesses. It was soon joined by the “Cylinder machine” which formed a multi-layered (multi-ply) type of paperboard. These machines were first installed in the United States around 1830

Introduction Paper and paperboard · Paperboard, boxboard, cardboard, and cartonboard are all terms used to describe heavier paper stock. · The International Organization for Standardization (ISO) states that material weighing more than 250 grams per square metre (511b per 1,000 sq. ft.) shall be known as paperboard. U.S. practice calls material that is more than 300(0.012 in.) thick paperboard

Introduction Paper and paperboard · Paperboard, boxboard, cardboard, and cartonboard are all terms used to describe heavier paper stock. · The International Organization for Standardization (ISO) states that material weighing more than 250 grams per square metre (511b per 1,000 sq. ft.) shall be known as paperboard. U.S. practice calls material that is more than 300(0.012 in.) thick paperboard

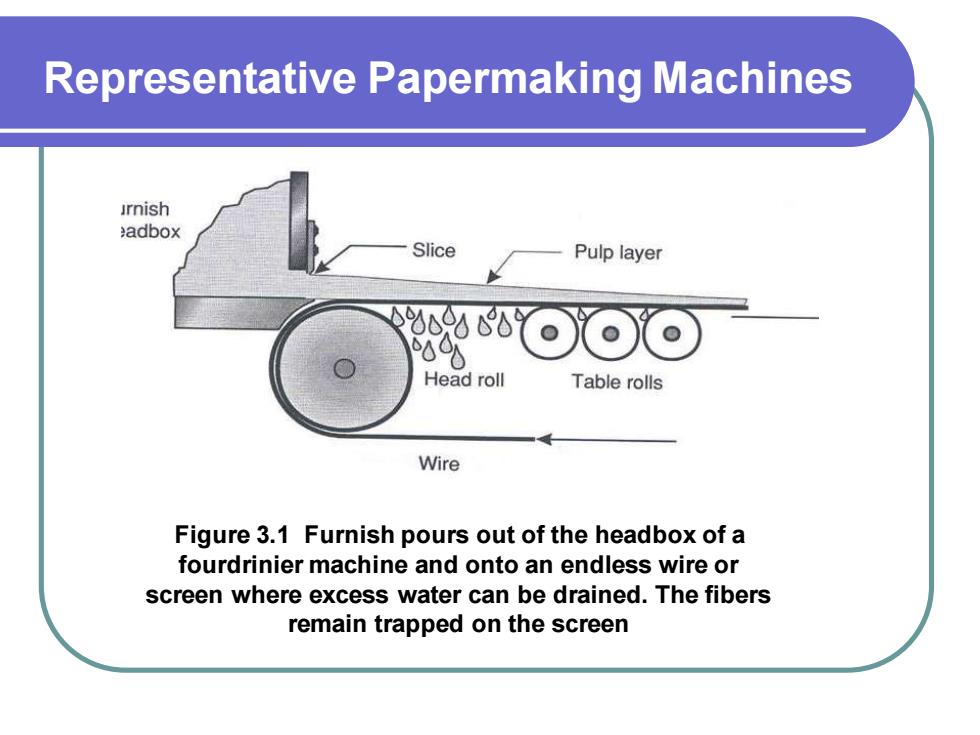

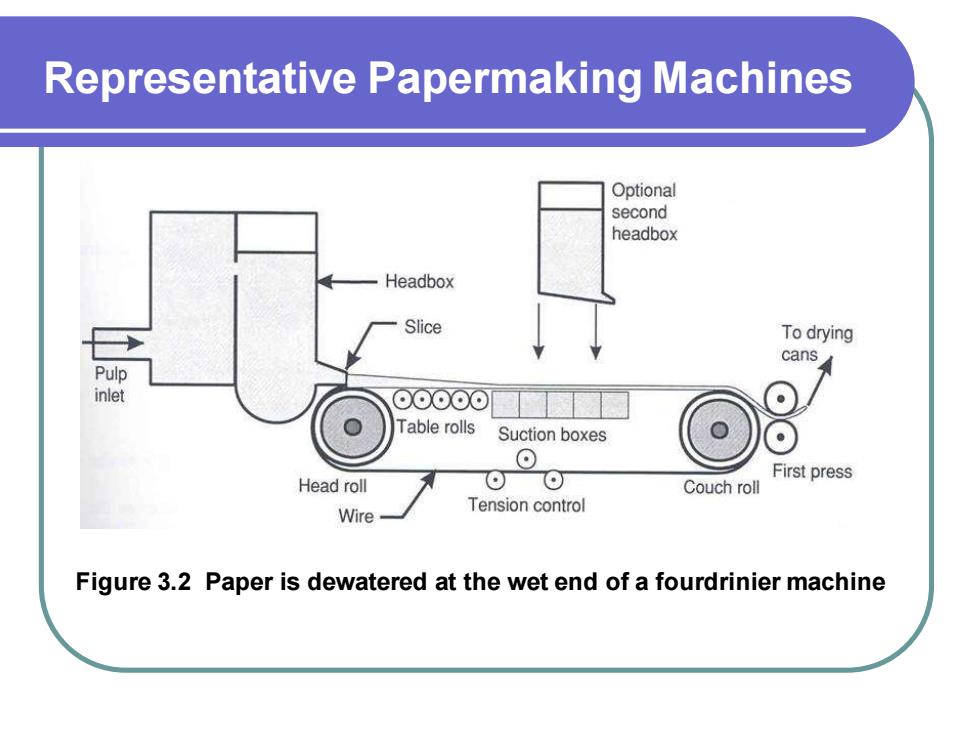

Representative Papermaking Machines Fourdrinier Machines Fourdrinier machines (Figure 3.1) pump furnish from a headbox directly onto a moving wire screen through which the water is continuously drained. Fourdrinier machines may have a second headbox (Figure 3.2)situated downstream of the first headbox to add further quantities of furnish onto the partially dewatered initial lay-down

Representative Papermaking Machines Fourdrinier Machines Fourdrinier machines (Figure 3.1) pump furnish from a headbox directly onto a moving wire screen through which the water is continuously drained. Fourdrinier machines may have a second headbox (Figure 3.2)situated downstream of the first headbox to add further quantities of furnish onto the partially dewatered initial lay-down

Representative Papermaking Machines Figure 3.1 Furnish pours out of the headbox of a fourdrinier machine and onto an endless wire or screen where excess water can be drained. The fibers remain trapped on the screen

Representative Papermaking Machines Figure 3.1 Furnish pours out of the headbox of a fourdrinier machine and onto an endless wire or screen where excess water can be drained. The fibers remain trapped on the screen

Representative Papermaking Machines Figure 3.2 Paper is dewatered at the wet end of a fourdrinier machine

Representative Papermaking Machines Figure 3.2 Paper is dewatered at the wet end of a fourdrinier machine

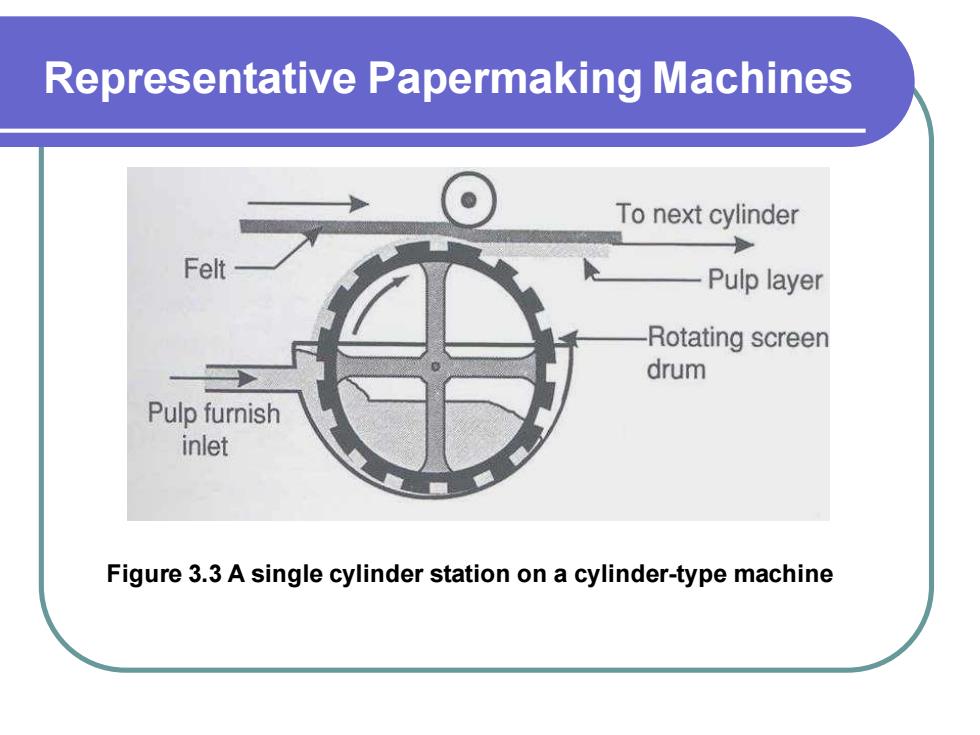

Representative Papermaking Machines Cylinder Machines A cylinder machine (Figure 3.3) rotates a screen drum in a vat of furnish. (The paper is sometimes called vat paper.) As the water pours through the screen, fiber accumulates on the outside of the screen. This thin layer of matted fiber is transferred onto a moving felt belt that passes sequentially over further rotating cylinders, each of which deposits another fiber layer

Representative Papermaking Machines Cylinder Machines A cylinder machine (Figure 3.3) rotates a screen drum in a vat of furnish. (The paper is sometimes called vat paper.) As the water pours through the screen, fiber accumulates on the outside of the screen. This thin layer of matted fiber is transferred onto a moving felt belt that passes sequentially over further rotating cylinders, each of which deposits another fiber layer

Representative Papermaking Machines Figure 3.3 A single cylinder station on a cylinder-type machine

Representative Papermaking Machines Figure 3.3 A single cylinder station on a cylinder-type machine