Lesson 20 Filling Systems 第20课 充填灌装系统

Lesson 20 Filling Systems 第20课 充填灌装系统

content ⚫ Introduction ⚫ Liquid Filling ⚫ Liquid Volumetric Filling ⚫ Liquid Constant Level Filling ⚫ Dry Product Filling ⚫ Dry Volumetric Filling ⚫ Dry Filling By Weight ⚫ Filling By Count

content ⚫ Introduction ⚫ Liquid Filling ⚫ Liquid Volumetric Filling ⚫ Liquid Constant Level Filling ⚫ Dry Product Filling ⚫ Dry Volumetric Filling ⚫ Dry Filling By Weight ⚫ Filling By Count

Introduction 1. What a filler can be asked to do? Fillers, filling machines, are used to transfer many types of products from bulk storage bins and vats into the containers in which they find their way to the market. The great variety of products that are packaged and the containers that they fill has caused the development of a large number of processes, techniques, and machines that are used for product filling

Introduction 1. What a filler can be asked to do? Fillers, filling machines, are used to transfer many types of products from bulk storage bins and vats into the containers in which they find their way to the market. The great variety of products that are packaged and the containers that they fill has caused the development of a large number of processes, techniques, and machines that are used for product filling

2. Considerations in selecting a filler ⚫ Types of products: from very thin liquids to semi-liquid products, pastes, and solids; stable, volatile, explosive, hot, frozen products. ⚫ Size, shape, and construction of the containers: glass bottles and jars, plastic bottles and cartons, paperboard boxes, metal cans, and plastic or paper bags. ⚫ Way the product is measured: by volume, weight, or count. Introduction

2. Considerations in selecting a filler ⚫ Types of products: from very thin liquids to semi-liquid products, pastes, and solids; stable, volatile, explosive, hot, frozen products. ⚫ Size, shape, and construction of the containers: glass bottles and jars, plastic bottles and cartons, paperboard boxes, metal cans, and plastic or paper bags. ⚫ Way the product is measured: by volume, weight, or count. Introduction

Introduction ⚫ Desired speed of the operation: a relatively slow manual operation, semi-automatic, fully automatic ( high speed lines) ⚫ Special handling requirements of the product ⚫ Cost of installation ⚫ Operation

Introduction ⚫ Desired speed of the operation: a relatively slow manual operation, semi-automatic, fully automatic ( high speed lines) ⚫ Special handling requirements of the product ⚫ Cost of installation ⚫ Operation

Liquid Filling 1. Introduction ⚫ Liquid products: alcohol and soda water ⚫ Semi-liquid products: toothpaste, peanut butter, and caulking compound

Liquid Filling 1. Introduction ⚫ Liquid products: alcohol and soda water ⚫ Semi-liquid products: toothpaste, peanut butter, and caulking compound

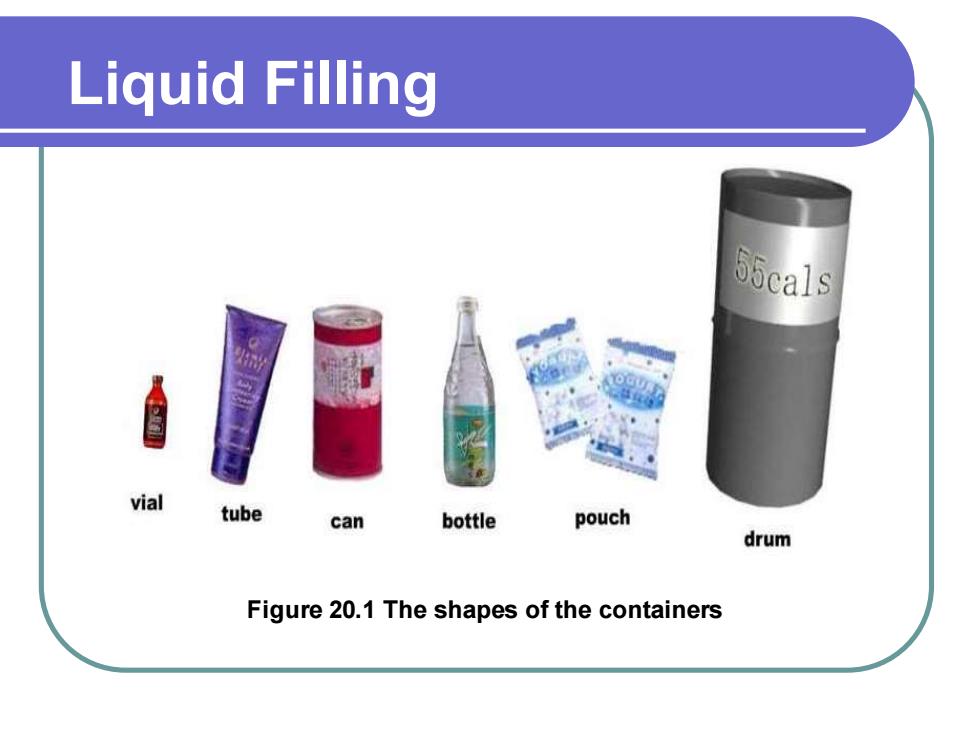

Liquid Filling 2. Types of Filling Machines ⚫ The containers may be made of plastic, metal, glass, treated paperboard, or a number of other materials. ⚫ The shapes of the containers include those of bottles, jars, vials, tubes, cans, pouches, cartons, and drums (Figure 20.1)

Liquid Filling 2. Types of Filling Machines ⚫ The containers may be made of plastic, metal, glass, treated paperboard, or a number of other materials. ⚫ The shapes of the containers include those of bottles, jars, vials, tubes, cans, pouches, cartons, and drums (Figure 20.1)

Figure 20.1 The shapes of the containers Liquid Filling

Figure 20.1 The shapes of the containers Liquid Filling

⚫ Most liquid and semi-liquid products are filled by one of two major methods: volumetric, or constant level filling. ⚫ In volumetric filling the amount of product is premeasured so that each container has the same volume of product. ⚫ Constant level filling techniques fill each container to the same level, so it is frequently called the “fill-to-a-level” method. Liquid Filling

⚫ Most liquid and semi-liquid products are filled by one of two major methods: volumetric, or constant level filling. ⚫ In volumetric filling the amount of product is premeasured so that each container has the same volume of product. ⚫ Constant level filling techniques fill each container to the same level, so it is frequently called the “fill-to-a-level” method. Liquid Filling

Liquid Filling 3. Use of Filling Machines ⚫ Volumetric filling is particularly appropriate for applications in the pharmaceutical industry where it is important that each container is accurately filled with a specific volume of product. ⚫ Constant level filling is used with see-through bottles in which it is important that all of the bottles in a display appear to be filled to the same level, although the bottles may not be exactly the same size and the volumes may be slightly different

Liquid Filling 3. Use of Filling Machines ⚫ Volumetric filling is particularly appropriate for applications in the pharmaceutical industry where it is important that each container is accurately filled with a specific volume of product. ⚫ Constant level filling is used with see-through bottles in which it is important that all of the bottles in a display appear to be filled to the same level, although the bottles may not be exactly the same size and the volumes may be slightly different