Lesson 14 Test Method for Product Fragility 第14课 产品脆值试验方法

Lesson 14 Test Method for Product Fragility 第14课 产品脆值试验方法

Test Method for Product Fragility ⚫ A shock machine is used to generate a damage boundary curve ⚫ A vibration system is used to map out the natural frequencies of a product

Test Method for Product Fragility ⚫ A shock machine is used to generate a damage boundary curve ⚫ A vibration system is used to map out the natural frequencies of a product

Shock: Damage Boundary Shock damage to products results from excessive internal stress induced by inertia forces - Since F=ma, shock fragility is characterized by the maximum tolerable acceleration level, i. e, how many g’s the item can withstand. - Why damaged? - How to reduce g’s ? The packaging material changes the shock pulse delivered to the product so that the maximum acceleration is greatly reduced (and the pulse duration is many times longer). - The package designer’s goal: To be sure that the g-level transmitted to the item by the cushion is less that the g-level which will cause the item to fail

Shock: Damage Boundary Shock damage to products results from excessive internal stress induced by inertia forces - Since F=ma, shock fragility is characterized by the maximum tolerable acceleration level, i. e, how many g’s the item can withstand. - Why damaged? - How to reduce g’s ? The packaging material changes the shock pulse delivered to the product so that the maximum acceleration is greatly reduced (and the pulse duration is many times longer). - The package designer’s goal: To be sure that the g-level transmitted to the item by the cushion is less that the g-level which will cause the item to fail

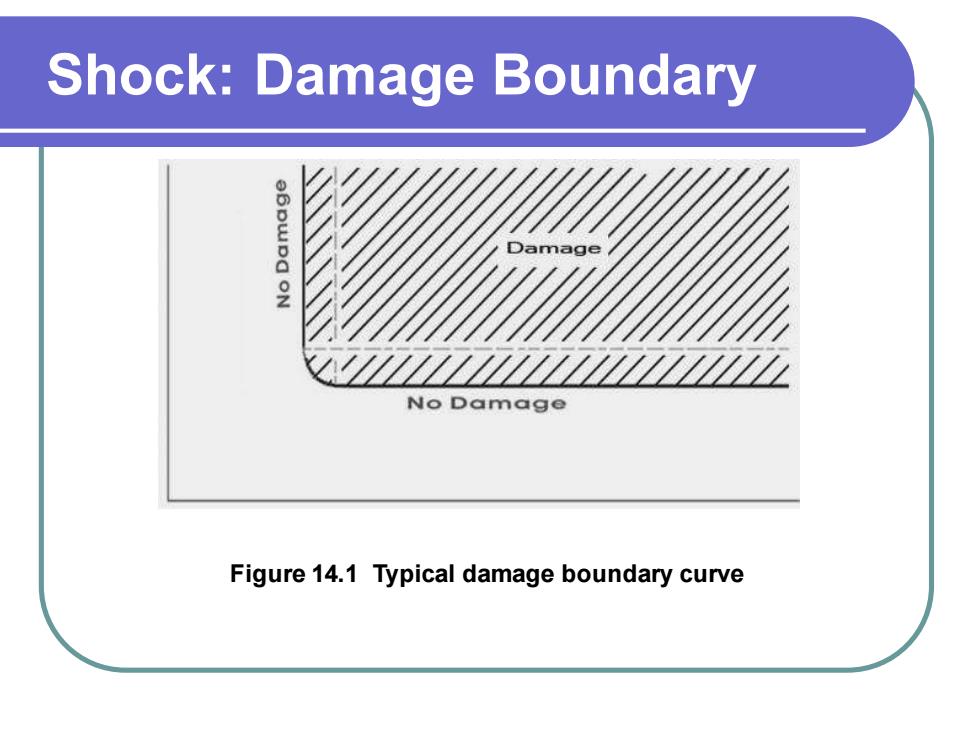

Shock: Damage Boundary The damage boundary theory is used to determine which shock inputs will cause damage to a product and which will not. - Two parts of a shock can cause damage: 1. the acceleration level A 2. the velocity change ∆V (the area under the acceleration-time history of the shock, thought as the energy contained in a shock) - The critical velocity change(∆Vc): a minimum velocity change which must be achieved before damage to the product can occur. 1. Below ∆Vc, no damage occurs regardless of the input A 2. Exceeding ∆Vc, does not necessarily imply that damage results. a. If ∆V occurs in a manner which administers acceptable doses of acceleration to the product, the velocity change can be very large without causing damage. b. If ∆Vc and Ac are both exceeded, damage occurs. Figure 14.1: Typical damage boundary curve

Shock: Damage Boundary The damage boundary theory is used to determine which shock inputs will cause damage to a product and which will not. - Two parts of a shock can cause damage: 1. the acceleration level A 2. the velocity change ∆V (the area under the acceleration-time history of the shock, thought as the energy contained in a shock) - The critical velocity change(∆Vc): a minimum velocity change which must be achieved before damage to the product can occur. 1. Below ∆Vc, no damage occurs regardless of the input A 2. Exceeding ∆Vc, does not necessarily imply that damage results. a. If ∆V occurs in a manner which administers acceptable doses of acceleration to the product, the velocity change can be very large without causing damage. b. If ∆Vc and Ac are both exceeded, damage occurs. Figure 14.1: Typical damage boundary curve

Shock: Damage Boundary Implications of Fig.14.1: a. if the input ∆Vthe product’s ∆Vc, However, the only way to avoid damage is to limit the input A < the product’s Ac. This is usually one of the functions that a cushioned package performs: it translates the high acceleration events experienced on the outside of the container to lower acceleration events experienced inside at the unit

Shock: Damage Boundary Implications of Fig.14.1: a. if the input ∆Vthe product’s ∆Vc, However, the only way to avoid damage is to limit the input A < the product’s Ac. This is usually one of the functions that a cushioned package performs: it translates the high acceleration events experienced on the outside of the container to lower acceleration events experienced inside at the unit

Shock: Damage Boundary Figure 14.1 Typical damage boundary curve

Shock: Damage Boundary Figure 14.1 Typical damage boundary curve

Shock: Damage Boundary c. For ∆V< ∆Vc, area where damage does not occur even with very high accelerations. Here ∆V (drop height) is so low that the item acts as its own shock isolator. d. <Ac, damage does not occur, even for large ∆V. That’s because the forces generated (F =ma) are within the strength limits of the products. - From Fig. 14.2, a. ∆Vc boundary (vertical boundary line), is independent of the pulse wave shape. b.Ac (to the right of the vertical line) for half sine and sawtooth pulses depends upon ∆V

Shock: Damage Boundary c. For ∆V< ∆Vc, area where damage does not occur even with very high accelerations. Here ∆V (drop height) is so low that the item acts as its own shock isolator. d. <Ac, damage does not occur, even for large ∆V. That’s because the forces generated (F =ma) are within the strength limits of the products. - From Fig. 14.2, a. ∆Vc boundary (vertical boundary line), is independent of the pulse wave shape. b.Ac (to the right of the vertical line) for half sine and sawtooth pulses depends upon ∆V

Shock: Damage Boundary Figure 14.2 Damage boundary for pulses of same peak acceleration and same velocity change

Shock: Damage Boundary Figure 14.2 Damage boundary for pulses of same peak acceleration and same velocity change

Shock: Damage Boundary c. The damage boundary generated with use of a trapezoidal pulse encloses the damage boundaries of all the other waveforms. - Fragility testing is the process used to establish damage boundaries of products. a. It is usually conducted on a shock testing machine. The procedure has been standardized (ASTM D3332, Mechanical-Shock Fragility of Products, Using Shock Machines). b. Procedure: the item to be tested is fastened to the top of a shock machine table and the table is subjected to controlled velocity changes and shock pulses. The shock table is raised to a preset drop height. It is then released, free falls and impacts against the base of the machine; it rebounds from the base and is arrested by a braking system so that only one impact occurs

Shock: Damage Boundary c. The damage boundary generated with use of a trapezoidal pulse encloses the damage boundaries of all the other waveforms. - Fragility testing is the process used to establish damage boundaries of products. a. It is usually conducted on a shock testing machine. The procedure has been standardized (ASTM D3332, Mechanical-Shock Fragility of Products, Using Shock Machines). b. Procedure: the item to be tested is fastened to the top of a shock machine table and the table is subjected to controlled velocity changes and shock pulses. The shock table is raised to a preset drop height. It is then released, free falls and impacts against the base of the machine; it rebounds from the base and is arrested by a braking system so that only one impact occurs

Shock: Damage Boundary c. For trapezoidal pulses, the programmer is a constant force pneumatic cylinder. The g-level of the trapezoidal pulse is controlled simply by adjusting the compressed gas pressure in the cylinder. The ∆V is controlled by adjusting drop height. A Shock Testing Machine (1)

Shock: Damage Boundary c. For trapezoidal pulses, the programmer is a constant force pneumatic cylinder. The g-level of the trapezoidal pulse is controlled simply by adjusting the compressed gas pressure in the cylinder. The ∆V is controlled by adjusting drop height. A Shock Testing Machine (1)