Advanced Planning Scheduling (APS) in Semiconductor Manufacturing: Challenges and Opportunities Cheng-song LI(Shihezi Univ.,Xinjiang) 先进生产计划及调度(APS) 在半导体制造业中面临的挑战和机遇 李成松(石河子大学,新疆)

1 先进生产计划及调度 (APS) 在半导体制造业中面临的挑战和机遇 李成松(石河子大学,新疆) Advanced Planning / Scheduling (APS) in Semiconductor Manufacturing: Challenges and Opportunities Cheng-song LI (Shihezi Univ., Xinjiang)

Agenda提纲 ▣Supply Chain 供应链 Advanced Planning/Scheduling (APS) 先进生产计划及调度 Advanced Planning System Case Study 先进生产计划系统实例 2

2 ❑ Supply Chain 供应链 ❑ Advanced Planning/Scheduling (APS) 先进生产计划及调度 ❑ Advanced Planning System Case Study 先进生产计划系统实例 Agenda 提纲

Agenda提纲 ▣Supply Chain 供应链 Advanced Planning/Scheduling (APS) 先进生产计划及调度 Advanced Planning System Case Study 先进生产计划系统实例

3 3 ❑ Supply Chain 供应链 ❑ Advanced Planning/Scheduling (APS) 先进生产计划及调度 ❑ Advanced Planning System Case Study 先进生产计划系统实例 Agenda 提纲

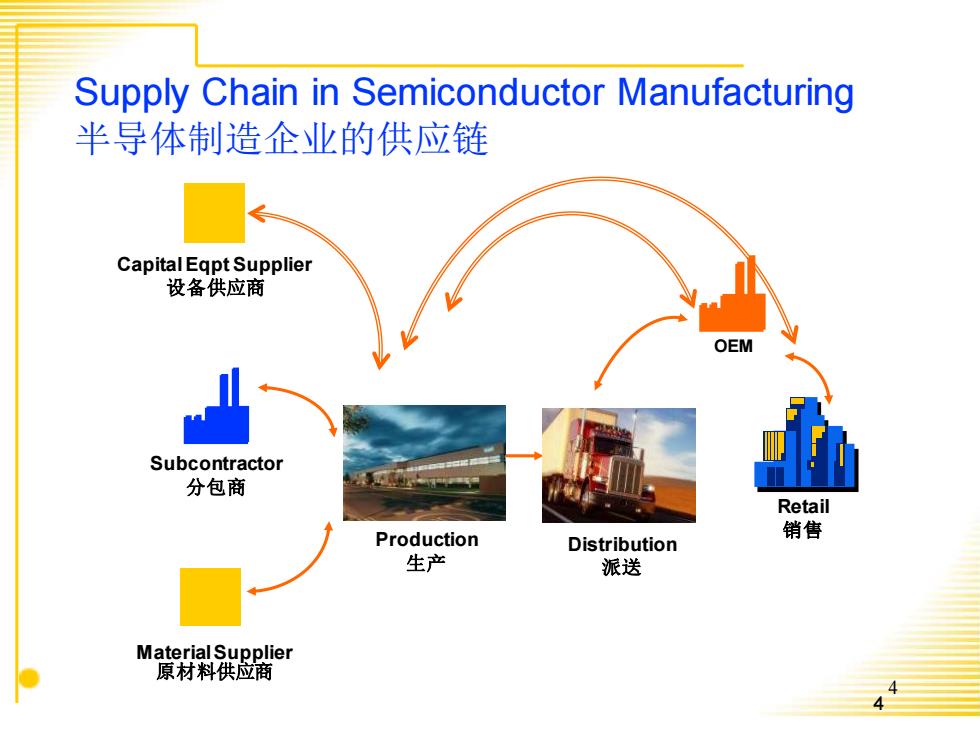

Supply Chain in Semiconductor Manufacturing 半导体制造企业的供应链 Capital Eqpt Supplier 设备供应商 OEM Subcontractor 分包商 Retail Production Distribution 销售 生产 派送 Material Supplier 原材料供应商

4 4 Supply Chain in Semiconductor Manufacturing 半导体制造企业的供应链 Material Supplier 原材料供应商 Retail 销售 Capital Eqpt Supplier 设备供应商 Subcontractor 分包商 OEM Production 生产 Distribution 派送

SCM Trend in Semiconductor Manufacturing 半导体制造企业供应链管理趋势 ▣Reduce inventories 减少库存 Move to build-to-order 按订货制造 Reduce planning cycle time 缩短计划制订时间 Improve delivery performance 提高计划制订水平 Focus on total Supply Chain Management(SCM) 专注于供应链整体优化 Collaborative planning and execution 整合计划和执行

5 5 ❑ Reduce inventories 减少库存 ❑ Move to build-to-order 按订货制造 ❑ Reduce planning cycle time 缩短计划制订时间 ❑ Improve delivery performance 提高计划制订水平 ❑ Focus on total Supply Chain Management (SCM) 专注于供应链整体优化 ❑ Collaborative planning and execution 整合计划和执行 SCM Trend in Semiconductor Manufacturing 半导体制造企业供应链管理趋势

Agenda提纲 ▣Supply Chain 供应链 Advanced Planning/Scheduling (APS) 先进生产计划及调度 口Advanced Planning System Case Study先进生产计划 系统实例 6

6 6 ❑ Supply Chain 供应链 ❑ Advanced Planning/Scheduling (APS) 先进生产计划及调度 ❑ Advanced Planning System Case Study 先进生产计划 系统实例 Agenda 提纲

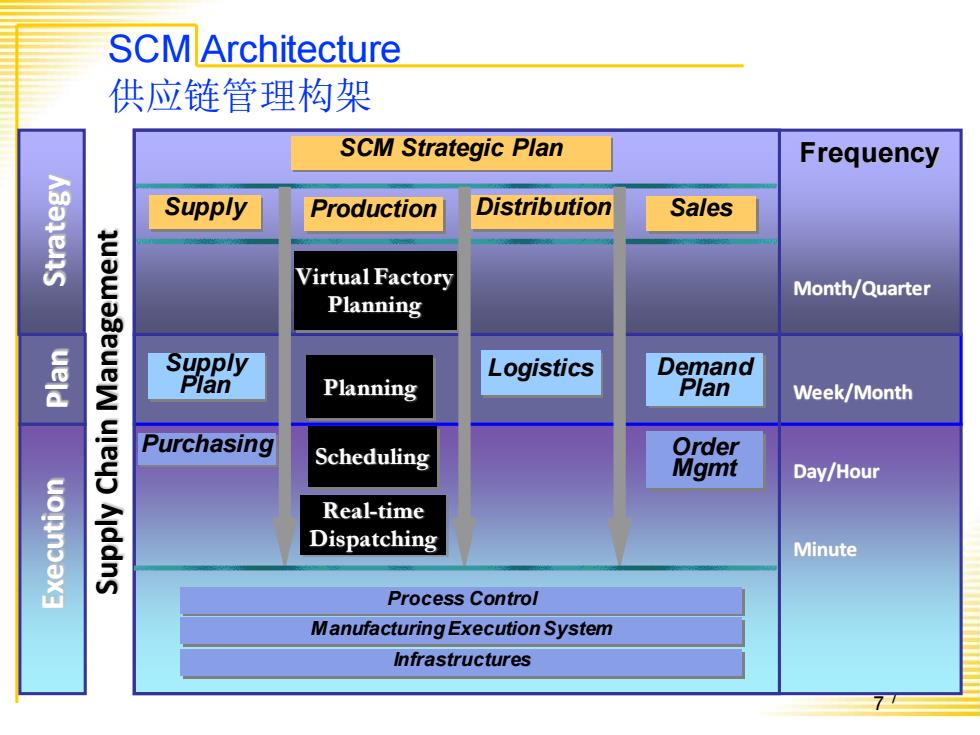

SCM Architecture 供应链管理构架 SCM Strategic Plan Frequency Supply Production Distribution Sales ueld quawaBeueW Virtual Factory Month/Quarter Planning Supply Logistics Demand Plan Planning Plan Week/Month uley) Purchasing Scheduling Order Mgmt Day/Hour Real-time Dispatching Minute Process Control Manufacturing Execution System Infrastructures

7 7 Purchasing Supply Plan Scheduling Logistics Planning Order Mgmt Demand Plan Supply Production Distribution Process Control Manufacturing Execution System Infrastructures SCM Strategic Plan Real-time Dispatching Virtual Factory Planning Sales Frequency Month/Quarter Week/Month Day/Hour Minute SCM Architecture 供应链管理构架 Strategy Plan Execution Supply Chain Management

Semiconductor Industry:Challenges 产业现状:挑战 口Marketing environment changes dramatically.半导体产业市场变化剧 烈。企业必须缩短市场反应时间,特别是生产计划的制定周期。 ▣ The cost of equipments is very high.半导体装备成本极高。主要设备 使用率的提高,能为公司节省巨额开支。 ▣ Semiconductor manufacturing is among the most complex production problems encountered today.半导体制造的复杂性和专业性,使其生 产管理成为最具挑战的课题。 ▣ Many enterprises lack expertise in IE/OR to apply APS.优秀的生产管 理系统需要先进工业工程(运筹)学成果支持。 In China中国国情: No domestic APS provider 无国内APS提供者。国外APS提供者产品价格高,服务尚未本地化 Production Management:guesswork,manual work 生产管理:主观臆断、手工计算 8 8

8 8 Semiconductor Industry: Challenges 产业现状:挑战 ❑ Marketing environment changes dramatically. 半导体产业市场变化剧 烈。企业必须缩短市场反应时间,特别是生产计划的制定周期。 ❑ The cost of equipments is very high. 半导体装备成本极高。主要设备 使用率的提高,能为公司节省巨额开支。 ❑ Semiconductor manufacturing is among the most complex production problems encountered today. 半导体制造的复杂性和专业性,使其生 产管理成为最具挑战的课题。 ❑ Many enterprises lack expertise in IE/OR to apply APS. 优秀的生产管 理系统需要先进工业工程(运筹)学成果支持。 In China 中国国情: ❑ No domestic APS provider 无国内APS提供者。国外APS提供者产品价格高,服务尚未本地化 ❑ Production Management: guesswork, manual work 生产管理:主观臆断、手工计算

Production Management:Current Status 生产管理现状 Lack of supply chain visibility 企业供应链透明度低 Inefficient production/distribution planning and execution 低效率生产/派送计划和执行 Long responsiveness TPT 客户响应速度慢 ▣Lack of flexibility 生产计划柔性差 Lack of optimization 生产计划优化程度差 ▣Poor on-time delivery 低及时交货率 High inventory,low turnover 高库存、低周转率 Competing management objectives 相互矛盾的生产管理目标 9

9 9 ❑ Lack of supply chain visibility 企业供应链透明度低 ❑ Inefficient production/distribution planning and execution 低效率生产/派送计划和执行 ❑ Long responsiveness TPT 客户响应速度慢 ❑ Lack of flexibility 生产计划柔性差 ❑ Lack of optimization 生产计划优化程度差 ❑ Poor on-time delivery 低及时交货率 ❑ High inventory, low turnover 高库存、低周转率 ❑ Competing management objectives 相互矛盾的生产管理目标 Production Management: Current Status 生产管理现状

Solution (Resource:ITRS*) 解决方案(源自TRS*) Significant improvements in factory planning/scheduling are required. 必须通过先进生产计划和调度系统来提高半导体制造的生产率 Improvements in factory forecasting and flexible factory information/control systems that can change with business conditions must be developed and implemented.必须改进工厂的需求预测,建 立柔性的工厂信息和管理软件系统,使得工厂产能可以随着市场环境 的改变而改变 .scheduling and dispatching.must be developed to improve equipment OEE and extendibility.必须探索和发展生产调度和分派技 术,以改进装备的利用率,提高工厂的可扩展性 International Technology Roadmap of Semiconductor 国际半导体技术路线图一半导体技术权威资料

10 10 Solution (Resource: ITRS*) 解决方案(源自ITRS*) ❑ Significant improvements in factory planning/scheduling are required. 必须通过先进生产计划和调度系统来提高半导体制造的生产率 ❑ Improvements in factory forecasting and flexible factory information/control systems that can change with business conditions must be developed and implemented. 必须改进工厂的需求预测,建 立柔性的工厂信息和管理软件系统,使得工厂产能可以随着市场环境 的改变而改变 ❑ . scheduling and dispatching. must be developed to improve equipment OEE and extendibility. 必须探索和发展生产调度和分派技 术,以改进装备的利用率,提高工厂的可扩展性 * International Technology Roadmap of Semiconductor 国际半导体技术路线图 - 半导体技术权威资料