盒 AO TONG U MT333 Materials Applications and Practice Superalloys in Aerospace A.Superalloys and Applications B.Superalloys Additive Manufacturing C.Superalloys Subtractive Manufacturing MT333 Materials Applications Practice Prof.XiaoQi Chen c.1 Superalloys Additive Manufacturing O TONG U Learning Goals 1.Understand and apply adaptive machining of superalloys 2.Understand and apply 3D Grinding of superalloys 3.Understand Concept of Material Removal Model MT333 Materials Applications&Practice Prof.XiaoQi Chen C.2

MT333 Materials Applications C.1 & Practice Prof. XiaoQi Chen MT333 Materials Applications and Practice A. Superalloys and Applications B. Superalloys Additive Manufacturing C. Superalloys Subtractive Manufacturing Superalloys in Aerospace MT333 Materials Applications C.2 & Practice Prof. XiaoQi Chen Superalloys Additive Manufacturing 1. Understand and apply adaptive machining of superalloys 2. Understand and apply 3D Grinding of superalloys 3. Understand Concept of Material Removal Model Learning Goals

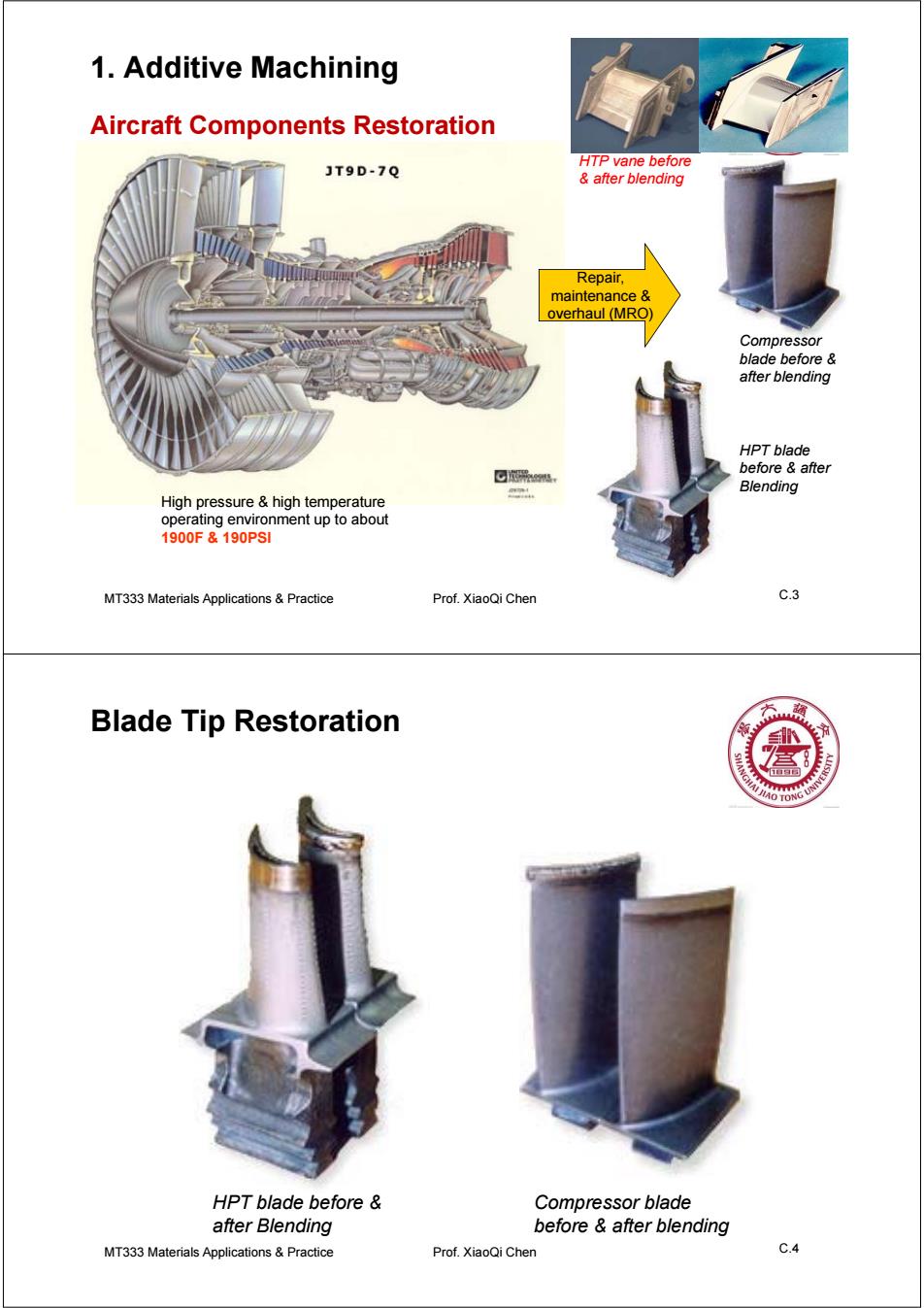

1.Additive Machining Aircraft Components Restoration JT9D-7Q HTP vane before after blending Repair. maintenance overhaul (MRO) Compressor blade before after blending HPT blade before after Blending High pressure high temperature operating environment up to about 1900F&190PSI MT333 Materials Applications Practice Prof.XiaoQi Chen C.3 Blade Tip Restoration O TONG UN HPT blade before Compressor blade after Blending before after blending MT333 Materials Applications&Practice Prof.XiaoQi Chen C.4

MT333 Materials Applications C.3 & Practice Prof. XiaoQi Chen 1. Additive Machining HPT blade before & after Blending Compressor blade before & after blending HTP vane before & after blending High pressure & high temperature operating environment up to about 1900F & 190PSI Repair, maintenance & overhaul (MRO) Aircraft Components Restoration MT333 Materials Applications C.4 & Practice Prof. XiaoQi Chen Blade Tip Restoration HPT blade before & after Blending Compressor blade before & after blending

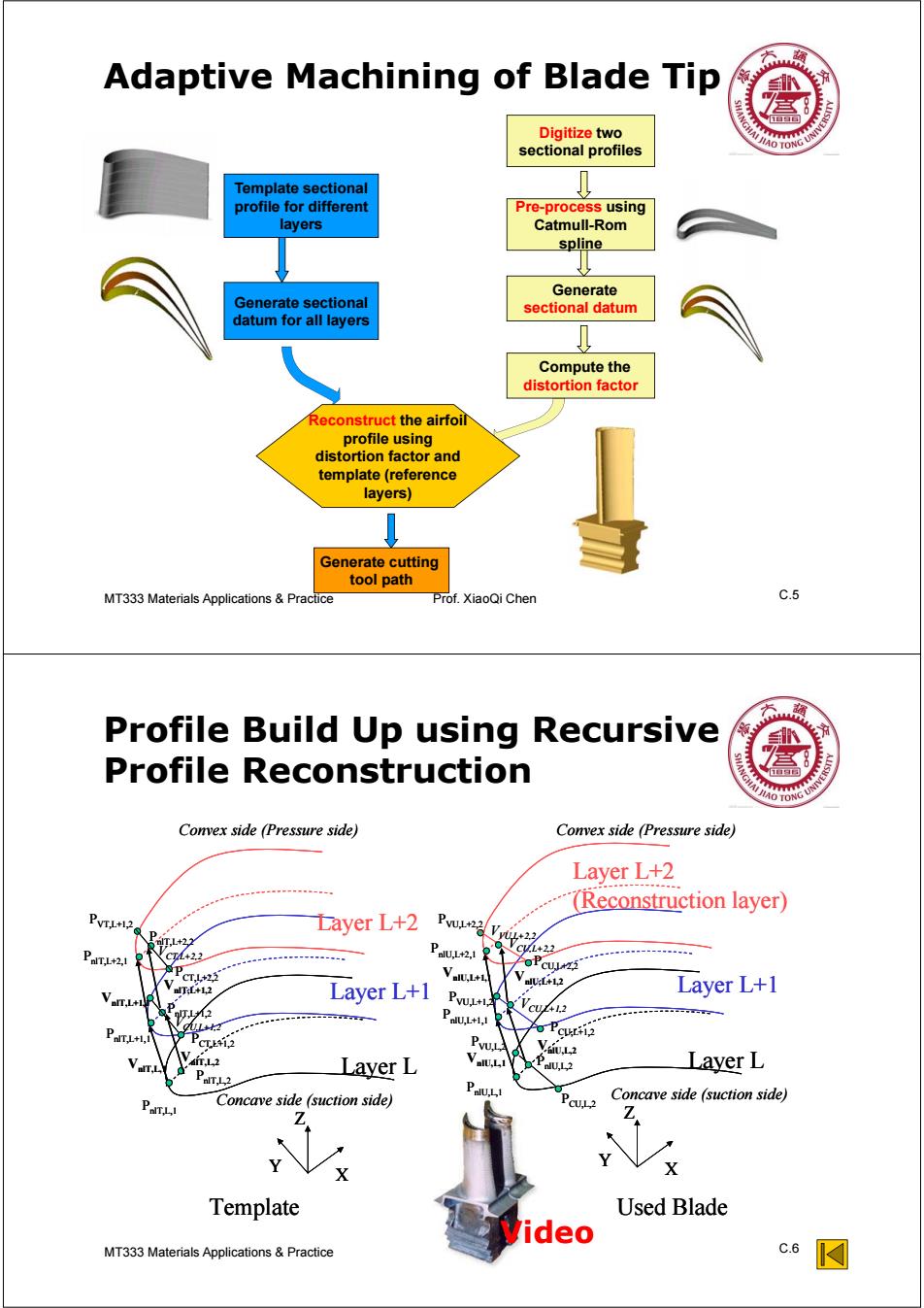

Adaptive Machining of Blade Tip 盒 Digitize two sectional profiles Template sectional profile for different Pre-process using layers Catmull-Rom spline Generate Generate sectional sectional datum datum for all layers ↓ Compute the distortion factor Reconstruct the airfoil profile using distortion factor and template (reference layers) Generate cutting tool path MT333 Materials Applications Practice Prof.XiaoQi Chen c.5 Profile Build Up using Recursive Profile Reconstruction Convex side (Pressure side) Convex side (Pressure side) Layer L+2 (Reconstruction layer) PVTL+12 Dayer L+2 TL+22 PaTL+21 PaUL2 CL+22 VaIU.L+L FoPcuwzi CT.L+22 alU:L+12 Layer L+1 Van.i+ olT:L+L2 Layer L+1 ,2 PaU.L+11 +l. o PCUL+i2 CT1,2 V,2 Layer L PaT12 Layer L Concave side (suction side) Concave side (suction side) Z Template Used Blade ideo MT333 Materials Applications&Practice C.6 ☑

MT333 Materials Applications C.5 & Practice Prof. XiaoQi Chen Adaptive Machining of Blade Tip Template sectional profile for different layers Digitize two sectional profiles Generate sectional datum for all layers Generate sectional datum Compute the distortion factor Generate cutting tool path Reconstruct the airfoil profile using distortion factor and template (reference layers) Pre-process using Catmull-Rom spline MT333 Materials Applications C.6 & Practice Prof. XiaoQi Chen Profile Build Up using Recursive Profile Reconstruction VnlU,L+1,1 VnlU,L,1 Layer L Layer L+2 (Reconstruction layer) Layer L+1 VCU,L+1,2 VCU,L+2,2 VnlT,L,1 VnlT,L+1,1 Layer L Layer L+2 Layer L+1 PnlT,L,1 PnlT,L+1,1 PnlT,L+2,1 Template Used Blade PnlT,L,2 PnlT,L+1,2 PVT,L+1,2 VnlT,L,2 VnlT,L+1,2 VnlU,L,2 VnlU,L+1,2 PCU,L,2 PCU,L+1,2 PCU,L+2,2 VVU,L+2,2 PVU,L+2,2 PnlU,L,1 PnlU,L+1,1 PnlU,L+2,1 X Z Y X Z Y Convex side (Pressure side) Concave side (suction side) Concave side (suction side) Convex side (Pressure side) PVU,L,2 PVU,L+1,2 PnlU,L,2 PCT,L+1,2 PnlT,L+2,2 PCT,L+2,2 VCU,L+1,2 VCT,L+2,2 VnlU,L+1,1 VnlU,L,1 Layer L Layer L+2 (Reconstruction layer) Layer L+1 VCU,L+1,2 VCU,L+2,2 VnlT,L,1 VnlT,L+1,1 Layer L Layer L+2 Layer L+1 PnlT,L,1 PnlT,L+1,1 PnlT,L+2,1 Template Used Blade PnlT,L,2 PnlT,L+1,2 PVT,L+1,2 VnlT,L,2 VnlT,L+1,2 VnlU,L,2 VnlU,L+1,2 PCU,L,2 PCU,L+1,2 PCU,L+2,2 VVU,L+2,2 PVU,L+2,2 PnlU,L,1 PnlU,L+1,1 PnlU,L+2,1 X Z Y X Z Y Convex side (Pressure side) Concave side (suction side) Concave side (suction side) Convex side (Pressure side) PVU,L,2 PVU,L+1,2 PnlU,L,2 PCT,L+1,2 PnlT,L+2,2 PCT,L+2,2 VCU,L+1,2 VCT,L+2,2 Video

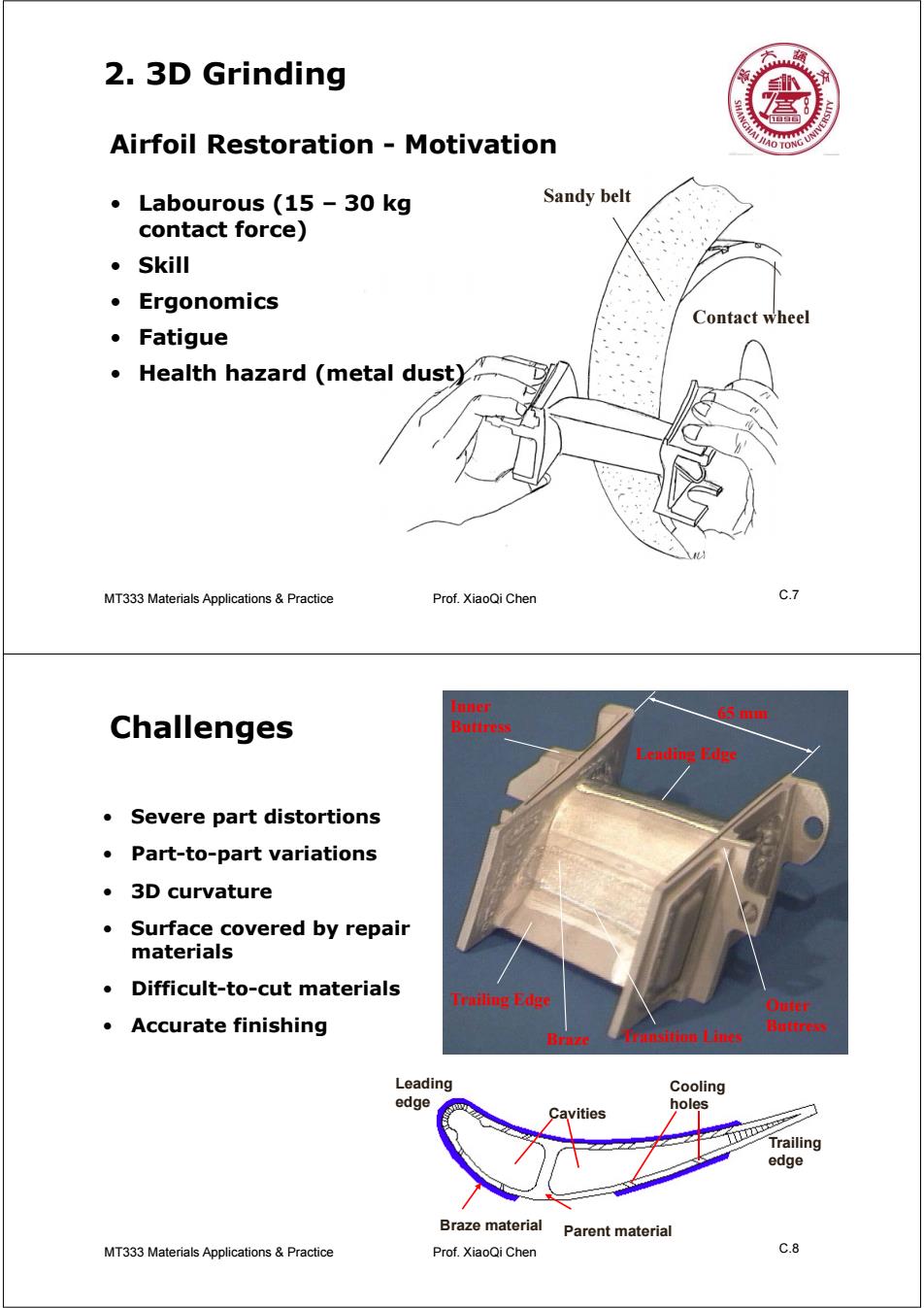

2.3D Grinding Airfoil Restoration Motivation JIAO TO ONG UN ·Labourous(15-30kg Sandy belt contact force) 。Skill ·Ergonomics Contact wheel ·Fatigue Health hazard (metal dust) MT333 Materials Applications Practice Prof.XiaoQi Chen C.7 Inner 65 mm Challenges Buttress Leading Edge Severe part distortions Part-to-part variations ·3 D curvature Surface covered by repair materials Difficult-to-cut materials Trailing Edge Oufer ·Accurate finishing Buttress Braze ansition Lines Leading Cooling edge holes Cavities Trailing edge Braze material Parent material MT333 Materials Applications&Practice Prof.XiaoQi Chen C.8

MT333 Materials Applications C.7 & Practice Prof. XiaoQi Chen 2. 3D Grinding Contact wheel Sandy belt • Labourous (15 – 30 kg contact force) • Skill • Ergonomics • Fatigue • Health hazard (metal dust) Airfoil Restoration - Motivation MT333 Materials Applications C.8 & Practice Prof. XiaoQi Chen Challenges 65 mm Trailing Edge Leading Edge Braze Outer Buttress Inner Buttress Transition Lines Braze material Parent material Leading edge Trailing edge Cavities Cooling holes • Severe part distortions • Part-to-part variations • 3D curvature • Surface covered by repair materials • Difficult-to-cut materials • Accurate finishing

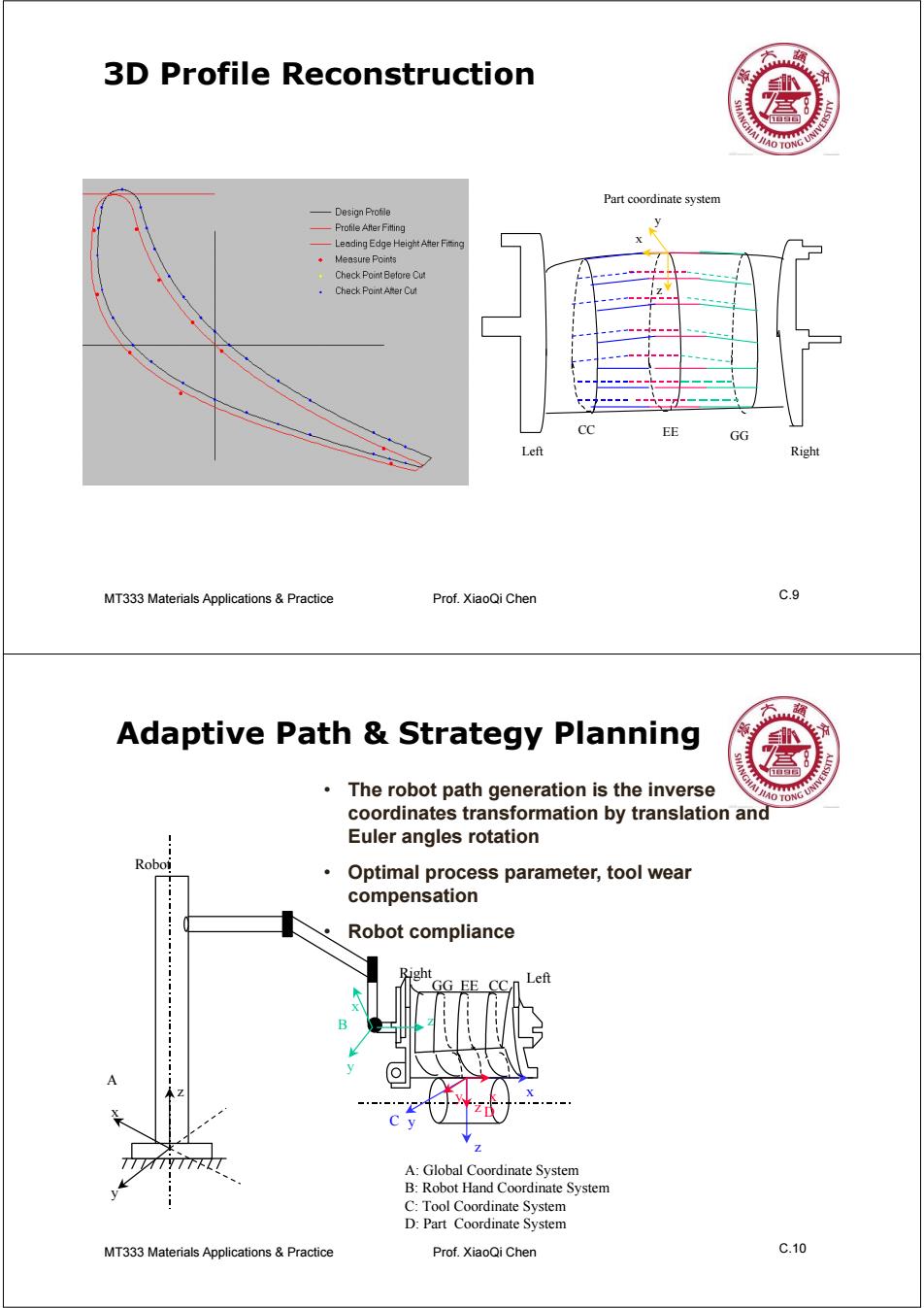

3D Profile Reconstruction 盒 AO TO Part coordinate system 一Design Profile Profile After Fitting Leading Edge Height After Fiting Measure Points Check Point Betore Cut Check Point ARer Cut GG Left Right MT333 Materials Applications Practice Prof.XiaoQi Chen c.9 Adaptive Path Strategy Planning The robot path generation is the inverse HO TONG UNN coordinates transformation by translation and Euler angles rotation Roboi Optimal process parameter,tool wear compensation Robot compliance Right GG EE Left 7 A:Global Coordinate System B:Robot Hand Coordinate System C:Tool Coordinate System D:Part Coordinate System MT333 Materials Applications&Practice Prof.XiaoQi Chen C.10

MT333 Materials Applications C.9 & Practice Prof. XiaoQi Chen 3D Profile Reconstruction CC EE GG x y z Part coordinate system Left Right MT333 Materials Applications C.10 & Practice Prof. XiaoQi Chen Adaptive Path & Strategy Planning x z y x y z x z y x y z GG EE CC A B C D A: Global Coordinate System B: Robot Hand Coordinate System C: Tool Coordinate System D: Part Coordinate System Robot Left Right • The robot path generation is the inverse coordinates transformation by translation and Euler angles rotation • Optimal process parameter, tool wear compensation • Robot compliance

Robot compliance principle 歌 Z-axis AO TC movement Workpiece Tool Abrasive Contact motor belt wheel R2KLS F=RKiLo+ R Spring Df D R1=D1 Rs=D D D: K:spring stiffness Displacement Lo:spring displacement due Tension Sensor(S) to preloading wheel MT333 Materials Applications Practice Prof.XiaoQi Chen C.11 Robot Compliance implementation O TONG UNN MT333 Materials Applications Practice Prof.XiaoQi Chen C.12 ☑

MT333 Materials Applications C.11 & Practice Prof. XiaoQi Chen Df Dt Tool motor Spring Displacement Sensor (S) Tension wheel Workpiece Contact wheel Z-axis movement Abrasive belt Ds F R K L S s l l R R K l l 2 0 t f D D Rl t s D D Rs Kl : spring stiffness L0: spring displacement due to preloading Robot compliance - principle MT333 Materials Applications C.12 & Practice Prof. XiaoQi Chen Robot Compliance - implementation

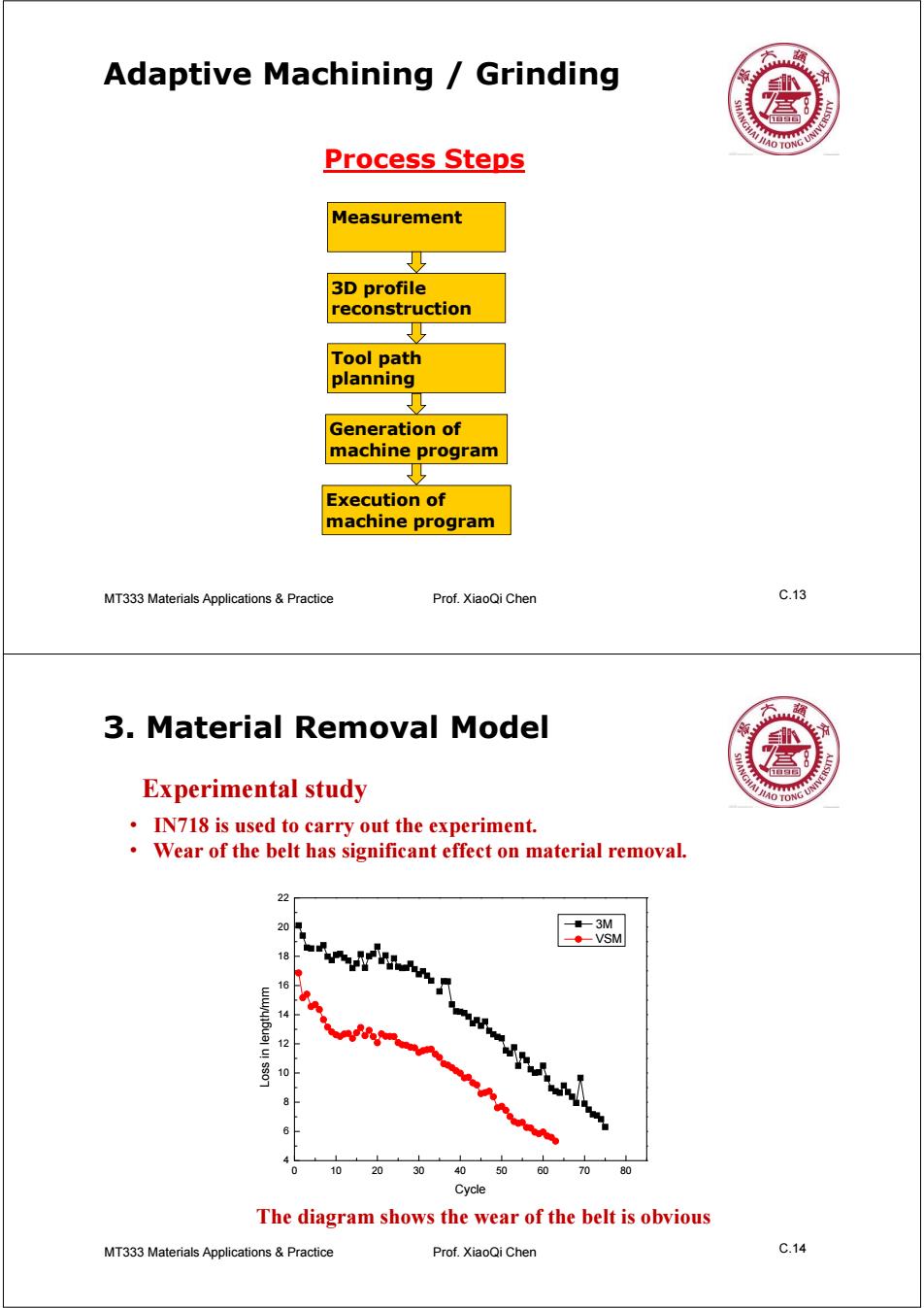

Adaptive Machining /Grinding HAO TO ONG UN Process Steps Measurement 女 3D profile reconstruction Tool path planning Generation of machine program Execution of machine program MT333 Materials Applications Practice Prof.XiaoQi Chen C.13 3.Material Removal Model Experimental study O TONG UN IN718 is used to carry out the experiment. Wear of the belt has significant effect on material removal. 2 -3M ◆-VSM 16 m-wn 12 10 20 30 40 50 60 70 80 Cycle The diagram shows the wear of the belt is obvious MT333 Materials Applications&Practice Prof.XiaoQi Chen C.14

MT333 Materials Applications C.13 & Practice Prof. XiaoQi Chen Adaptive Machining / Grinding Measurement 3D profile reconstruction Tool path planning Generation of machine program Process Steps Execution of machine program MT333 Materials Applications C.14 & Practice Prof. XiaoQi Chen Experimental study • IN718 is used to carry out the experiment. • Wear of the belt has significant effect on material removal. 0 10 20 30 40 50 60 70 80 4 6 8 10 12 14 16 18 20 22 Loss in length/mm Cycle 3M VSM The diagram shows the wear of the belt is obvious 3. Material Removal Model

Modelling Methods HAO TO ONG UN Input and output parameters Wheel speed Roughness Grinding force Model Removal rate Wear of belt Model construction Wear of belt,which is quantified by the working time of the belt,is contained in the model to improve the predicting accuracy. Wheel speed and grinding force are set with four levels to carry out experiment. MT333 Materials Applications Practice Prof.XiaoQi Chen C.15 ANN modelling ·Black-box approach. AO TONG U Use neural network to represent input-output relationship. Use available to train NN 35 -Predicting value of roughness/um Predicting value of loss/g A-True value of roughness/um 30 -True value of loss/g 25 20 10 Output of ANN modeling MT333 Materials Applications&Practice Prof.XiaoQi Chen C.16

MT333 Materials Applications C.15 & Practice Prof. XiaoQi Chen Model Wheel speed Grinding force Wear of belt Roughness Removal rate Model construction Input and output parameters • Wear of belt, which is quantified by the working time of the belt, is contained in the model to improve the predicting accuracy. • Wheel speed and grinding force are set with four levels to carry out experiment. Modelling Methods MT333 Materials Applications C.16 & Practice Prof. XiaoQi Chen 2 4 6 8 10 12 5 10 15 20 25 30 35 Predicting value of roughness/um Predicting value of loss/g True value of roughness/um True value of loss/g Output of ANN modeling ANN modelling • Black-box approach. • Use neural network to represent input-output relationship. • Use available to train NN

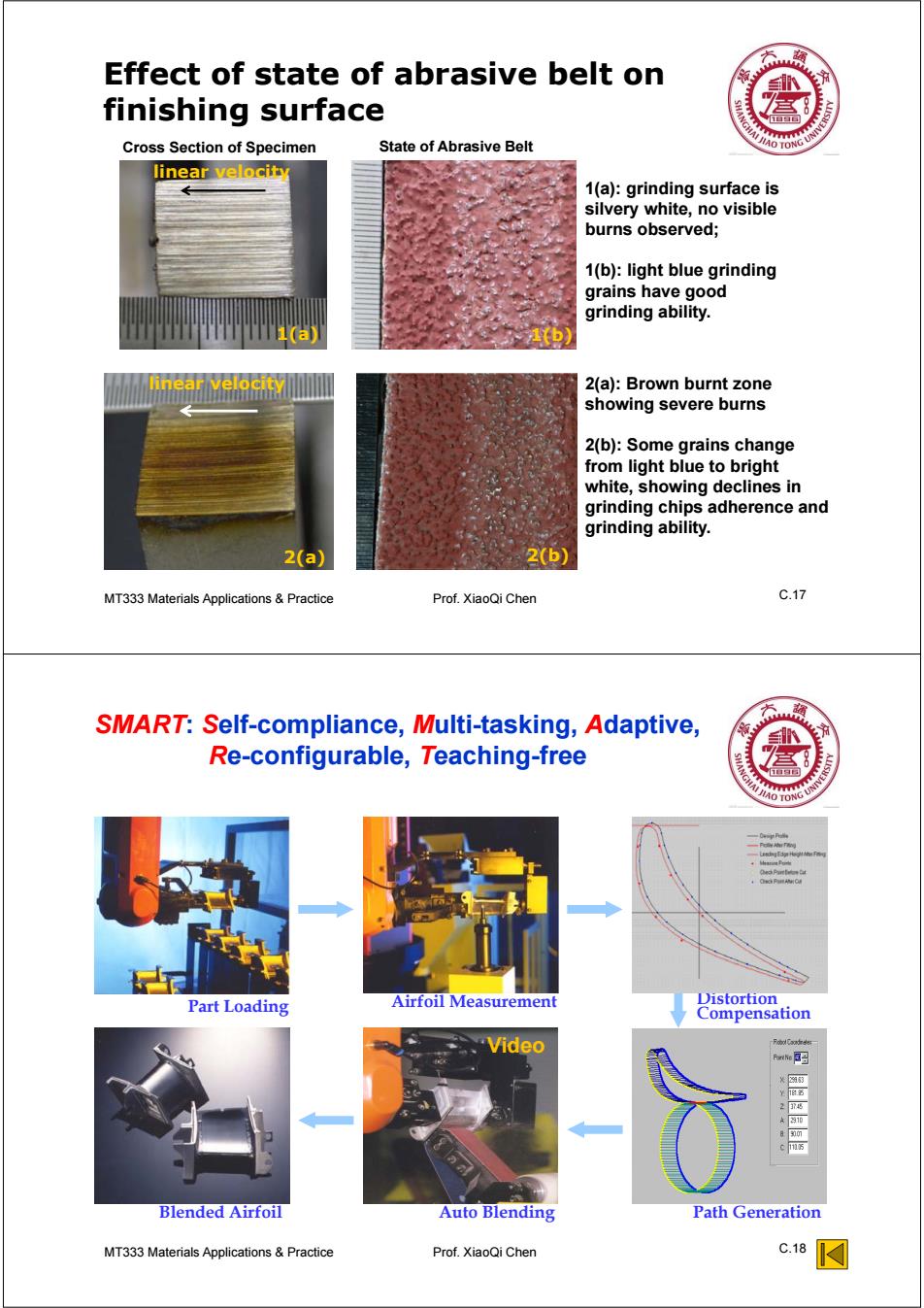

Effect of state of abrasive belt on finishing surface Cross Section of Specimen State of Abrasive Belt JIAO TO linear velocity 1(a):grinding surface is silvery white,no visible burns observed; 1(b):light blue grinding grains have good grinding ability. 2(a):Brown burnt zone showing severe burns 2(b):Some grains change from light blue to bright white,showing declines in grinding chips adherence and grinding ability. 2(a) MT333 Materials Applications Practice Prof.XiaoQi Chen C.17 SMART:Self-compliance,Multi-tasking,Adaptive, Re-configurable,Teaching-free O TONG U Part Loading Airfoil Measurement Distortion Compensation ..Video Fooe a图 米1的 cm Blended Airfoil Auto Blending Path Generation MT333 Materials Applications Practice Prof.XiaoQi Chen C.18

MT333 Materials Applications C.17 & Practice Prof. XiaoQi Chen Effect of state of abrasive belt on finishing surface linear velocity Cross Section of Specimen State of Abrasive Belt 1(a): grinding surface is silvery white, no visible burns observed; 1(b): light blue grinding grains have good grinding ability. linear velocity 2(a): Brown burnt zone showing severe burns 2(b): Some grains change from light blue to bright white, showing declines in grinding chips adherence and grinding ability. 1(a) 1(b) 2(a) 2(b) MT333 Materials Applications C.18 & Practice Prof. XiaoQi Chen Part Loading Auto Blending Path Generation Distortion Compensation Airfoil Measurement Blended Airfoil SMART: Self-compliance, Multi-tasking, Adaptive, Re-configurable, Teaching-free Video