JIAOTONG UNIVERSIT 196 Supply Chain Management Lecture 6 Supply Chain Network Design Instructor(s) Prof.Jianjun Gao Department of Automation School of Electronic Information and Electrical Engineering SCM by J.J.Gao SEIEE AU406

Supply Chain Management Instructor(s) SEIEE AU406 + - SCM by J. J. Gao Supply Chain Network Design Prof. Jianjun Gao Department of Automation School of Electronic Information and Electrical Engineering Lecture 6

Outline The Role of Network Design in the Supply Chain s Factors Influencing Network Design Decisions Framework For Network Design Models for Facility location and Capacity allocation The capacitated plant location model Gravity Location Model Locating Plants:the capacitated plant location model with single sourcing Summary SCM by J.J.Gao SEIEE AU406 2

SEIEE AU406 + - The Role of Network Design in the Supply Chain Factors Influencing Network Design Decisions Framework For Network Design Models for Facility location and Capacity allocation The capacitated plant location model Gravity Location Model Locating Plants: the capacitated plant location model with single sourcing Summary 2 Outline SCM by J. J. Gao

The Role of Network Design in the Supply Chain Supply chain network design decisions include the assignment of facility role;location of manufacturing, storage,or transportation-related facilities;and the allocation of capacity and markets to each facility. Supply chain network design decisions are classified as follows: Facility role:What role should each facility play?What processes are performed at each facility? Facility location:Where should facilities be located? Capacity allocation:How much capacity should be allocated to each facility? Market and supply allocation:What markets should each facility serve?Which supply sources should feed each facility? SCM by J.J.Gao SEIEE AU406 3

SEIEE AU406 + - Supply chain network design decisions include the assignment of facility role; location of manufacturing, storage, or transportation-related facilities; and the allocation of capacity and markets to each facility. Supply chain network design decisions are classified as follows: Facility role: What role should each facility play? What processes are performed at each facility? Facility location: Where should facilities be located? Capacity allocation: How much capacity should be allocated to each facility? Market and supply allocation: What markets should each facility serve? Which supply sources should feed each facility? 3 The Role of Network Design in the Supply Chain SCM by J. J. Gao

The Role of Network Design in the Supply Chain Facility location decisions have a long-term impact on a supply chain's performance because it is expensive to shut down a facility or move it to a different location. Capacity allocation can be altered more easily than location, capacity decisions do tend to stay in place for several years The allocation of supply sources and markets to facilities has a significant impact on performance Network design decisions must be revisited as market conditions change or when two companies merge SCM by J.J.Gao SEIEE AU406 4

SEIEE AU406 + - Facility location decisions have a long-term impact on a supply chain’s performance because it is expensive to shut down a facility or move it to a different location. Capacity allocation can be altered more easily than location, capacity decisions do tend to stay in place for several years The allocation of supply sources and markets to facilities has a significant impact on performance Network design decisions must be revisited as market conditions change or when two companies merge 4 SCM by J. J. Gao The Role of Network Design in the Supply Chain

Factors Influencing Network Design Decisions ▣Strategic Factor ▣Foxconn,Zara Technological Factor ▣ semiconductor companies build a few high-capacity facilities. Coca-Cola sets many factories Macroeconomic Factors Tariffs and tax incentives Exchange-Rate and demand risk:Yen V.S.Dollar ▣Freight and Fuel Cost ▣Political Factors Infrastructure Factors SCM by J.J.Gao SEIEE AU406 5

SEIEE AU406 + - 5 Factors Influencing Network Design Decisions SCM by J. J. Gao Strategic Factor Foxconn, Zara Technological Factor semiconductor companies build a few high-capacity facilities. Coca-Cola sets many factories Macroeconomic Factors Tariffs and tax incentives Exchange-Rate and demand risk: Yen V.S. Dollar Freight and Fuel Cost Political Factors Infrastructure Factors

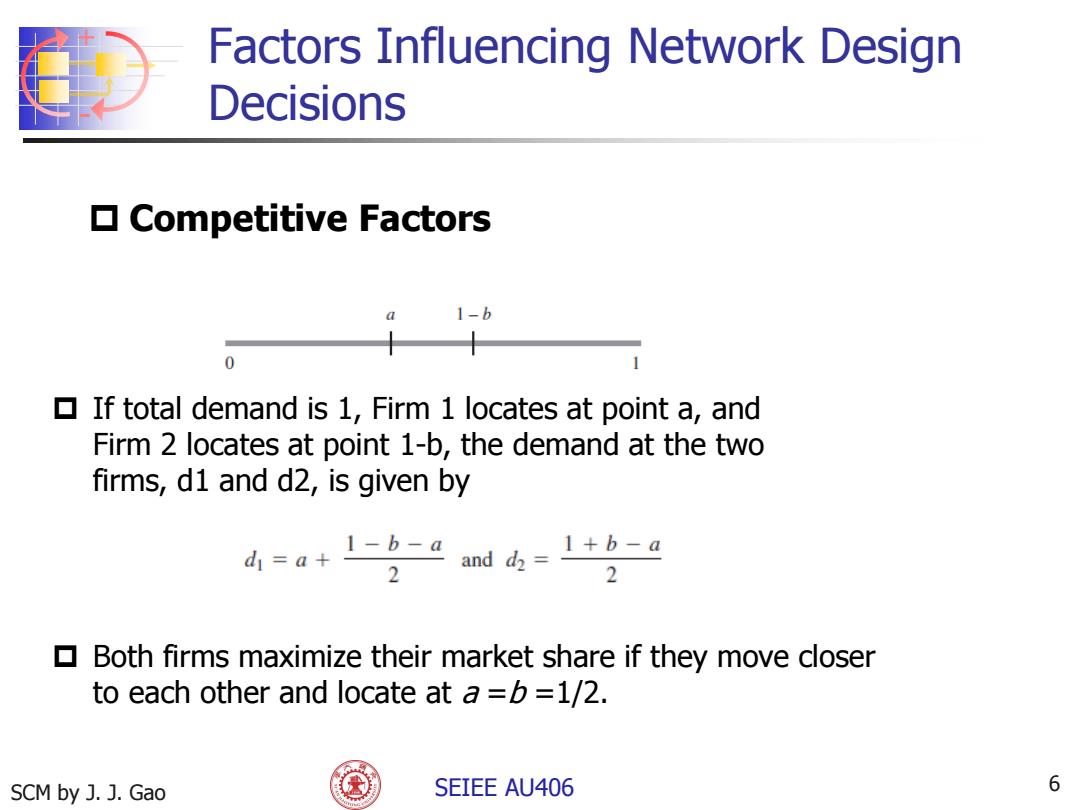

Factors Influencing Network Design Decisions ▣Competitive Factors 1-b 0 1 If total demand is 1,Firm 1 locates at point a,and Firm 2 locates at point 1-b,the demand at the two firms,d1 and d2,is given by di=a+I-b-a and d2= 1+b-a 2 2 Both firms maximize their market share if they move closer to each other and locate at a =b=1/2. SCM by J.J.Gao SEIEE AU406 6

SEIEE AU406 + - 6 SCM by J. J. Gao Factors Influencing Network Design Decisions Competitive Factors If total demand is 1, Firm 1 locates at point a, and Firm 2 locates at point 1-b, the demand at the two firms, d1 and d2, is given by Both firms maximize their market share if they move closer to each other and locate at a =b =1/2

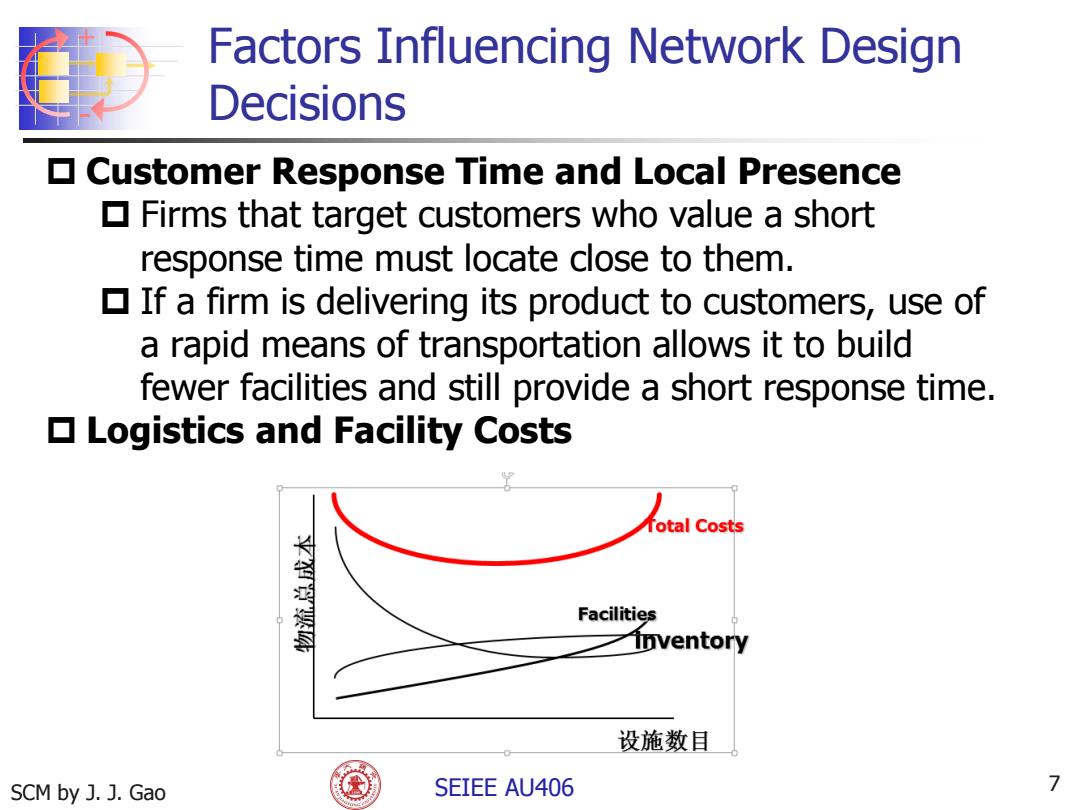

Factors Influencing Network Design Decisions ▣ Customer Response Time and Local Presence Firms that target customers who value a short response time must locate close to them. If a firm is delivering its product to customers,use of a rapid means of transportation allows it to build fewer facilities and still provide a short response time. Logistics and Facility Costs Total Costs Facilities Inventory 设施数目 SCM by J.J.Gao SEIEE AU406 7

SEIEE AU406 + - 7 SCM by J. J. Gao Factors Influencing Network Design Decisions Customer Response Time and Local Presence Firms that target customers who value a short response time must locate close to them. If a firm is delivering its product to customers, use of a rapid means of transportation allows it to build fewer facilities and still provide a short response time. Logistics and Facility Costs

Framework of Network Design COMPETITIVE STRATEGY PHASEI Supply Chain GLOBAL COMPETITION INTERNAL CONSTRAINTS Strategy Capital,growth strategy, existing network PRODUCTION TARIFFS AND TAX TECHNOLOGIES INCENTIVES Cost,scale/scope impact. support required,flexibility PHASE II REGIONAL DEMAND Regional Facility Size,growth,homogeneity, COMPETITIVE Configuration local specifications ENVIRONMENT POLITICAL, AGGREGATE FACTOR AND EXCHANGE RATE. LOGISTICS COSTS AND DEMAND RISK PRODUCTION METHODS PHASE III AVAILABLE Skill needs,response time Desirable Sites INFRASTRUCTURE FACTOR COSTS LOGISTICS COSTS Labor,materials,site specific PHASE IV Transport,inventory, Location Choices coordination 8 FIGURE 5-2 Framework for Network Design Decisions

SEIEE AU406 + - 8 Framework of Network Design SCM by J. J. Gao

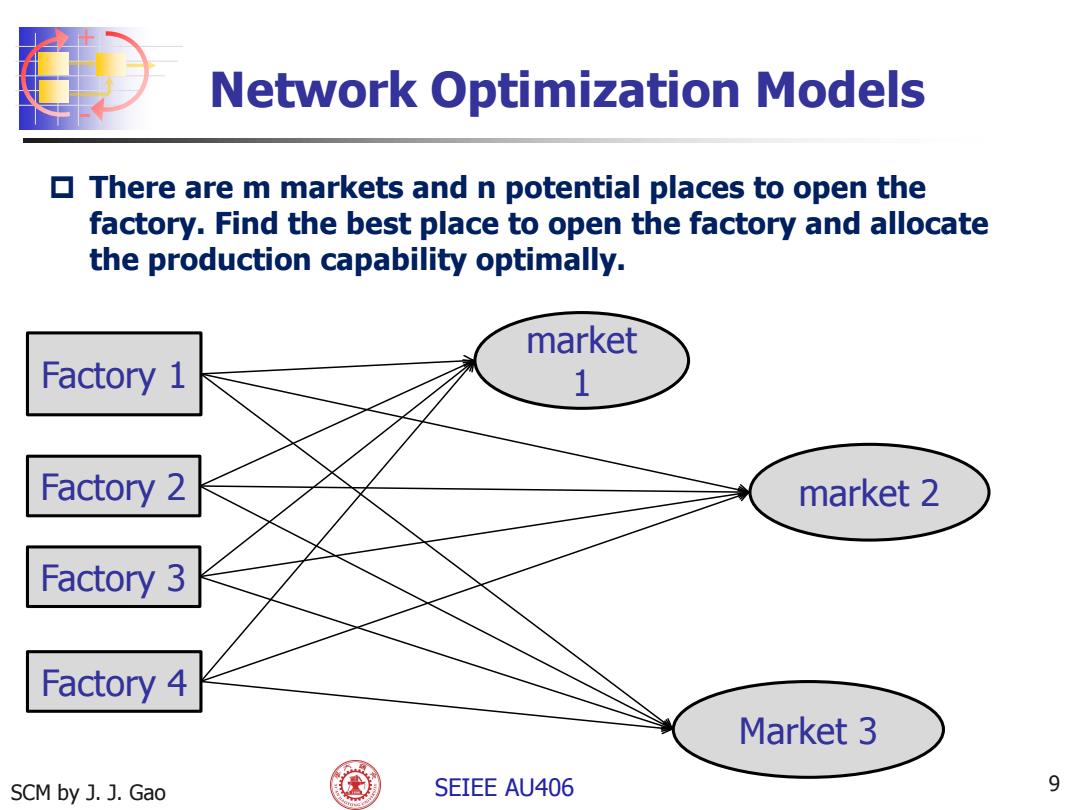

Network Optimization Models ▣ There are m markets and n potential places to open the factory.Find the best place to open the factory and allocate the production capability optimally. market Factory 1 1 Factory 2 market 2 Factory 3 Factory 4 Market 3 SCM by J.J.Gao 国 SEIEE AU406 9

SEIEE AU406 + - 9 SCM by J. J. Gao Network Optimization Models Factory 1 Factory 2 Factory 3 Factory 4 market 1 market 2 Market 3 There are m markets and n potential places to open the factory. Find the best place to open the factory and allocate the production capability optimally

Network Optimization Models Parameters: n=number of potential plant locations/capacity (each level of capacity will count as a separate location) m number of markets or demand points Di=annual demand from market j Ki=potential capacity of plant i fi=annualized fixed cost of keeping plant i open cyj cost of producing and shipping one unit from plant i to market j(cost includes production,inventory,transportation,and tariffs) Decision Variables: yi 1 if plant i is open,0 otherwise xij=quantity shipped from plant i to market j SCM by J.J.Gao SEIEE AU406 10

SEIEE AU406 + - 10 SCM by J. J. Gao Network Optimization Models Parameters: Decision Variables: